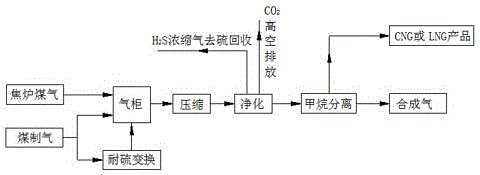

Method used for producing synthesis gas from coke oven gas and coal gas

A coke oven gas and coal-to-gas technology, applied in hydrogen production, gas fuel, petroleum industry, etc., to achieve the effect of single process, controllable hydrogen-carbon ratio, and easy operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The coke oven gas produced by the top-loading coke oven (volume percentage composition is H 2 : 55%, CH 4 : 25%, CO+CO 2 :15%, N 2 : 5%) and 80% volume of coal-to-gas produced by pressurized gasification of crushed coal (volume percentage composition is CO: 49%, H 2 : 24%, CO 2 : 14%, CH 4 : 13%, H 2 S: 0.25%) into the gas holder, the molar flow ratio of coke oven gas and coal-based gas is 1.35:1, and another part of 20% of the volume of coal-based gas enters the sulfur-resistant water-vapour conversion equipped with Qingdao Lianxin QDB series catalyst, Airspeed is 2600h -1 , pressure 3.0MPa, temperature 360°C for sulfur-resistant transformation, the transformation gas and the mixed gas are combined and compressed to form a crude raw material gas with a hydrogen-carbon molar ratio of 2.28, and the crude raw material gas is washed and purified with low-temperature methanol after compression. Remove H at a pressure of 4.0MPa and a temperature of -45°C 2 S and CO ...

Embodiment 2

[0038] The coke oven gas (volume percentage composition as H 2 : 62%, CH 4 : 23%, CO+CO 2 :10%,N 2 : 5%) and about 90% of the volume of coal-to-gas produced by pressurized gasification of crushed coal (volume percentage composition is CO: 59%, H 2 : 20%, CO 2 : 12%, CH 4 : 9%, H 2 S: 0.35%) into the gas holder, the molar flow ratio of coke oven gas and coal-to-gas is 2.0:1, and another part of about 10% of the volume of coal-to-gas enters the QCS-01 catalyst produced by Qilu Petrochemical Research Institute. Sulfur-water-vapor shift at a space velocity of 3300h -1 , pressure 3.5MPa, temperature 380°C for sulfur-resistant transformation, the transformation gas and the mixed gas are combined and compressed to form a crude raw material gas with a hydrogen-carbon molar ratio of 2.36, and the crude raw material gas is purified by thermal alkali method after compression. Removal of H at a pressure of 1.4MPa and a temperature of 100°C 2 S and CO 2 and other impurities to obt...

Embodiment 3

[0040] The coke oven gas produced by the top-loading coke oven (volume percentage composition is H 2 : 60%, CH 4 : 24%, CO+CO 2 :12%,N 2 : 4%) and about 70% volume of coal-to-gas produced by Lurgi furnace gasification (volume percentage composition is CO: 50%, H 2 : 25%, CO 2 : 10%, CH 4 : 15%, H 2 S: 0.28%) into the gas holder, the molar flow ratio of coke oven gas and coal-based gas is 1.5:1, and another part of about 30% of the volume of coal-based gas enters the K8-11 type catalyst produced by the British ICI company. Sulfur-water vapor shift, at a space velocity of 5800h -1 , pressure 4.0MPa, temperature 370°C for sulfur-resistant shifting, the shifted gas and the mixed gas are combined and compressed to form a crude raw material gas with a hydrogen-carbon molar ratio of 3.11, and the crude raw material gas is purified by NHD after compression. 2.8MPa, H removal at 1°C 2 S and CO 2 and other impurities to obtain H 2 S content is less than 0.1ppm, CO 2 Feed gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com