Quick and high-precision method for manufacturing layered modular die based on laser combination processing technology

A technology that combines processing and manufacturing methods, applied in manufacturing tools, laser welding equipment, metal processing equipment, etc., can solve the problems of mold strength, poor surface wear resistance, complex process, and complex realization process, and achieve overall performance requirements. , Clean and pollution-free processing, the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

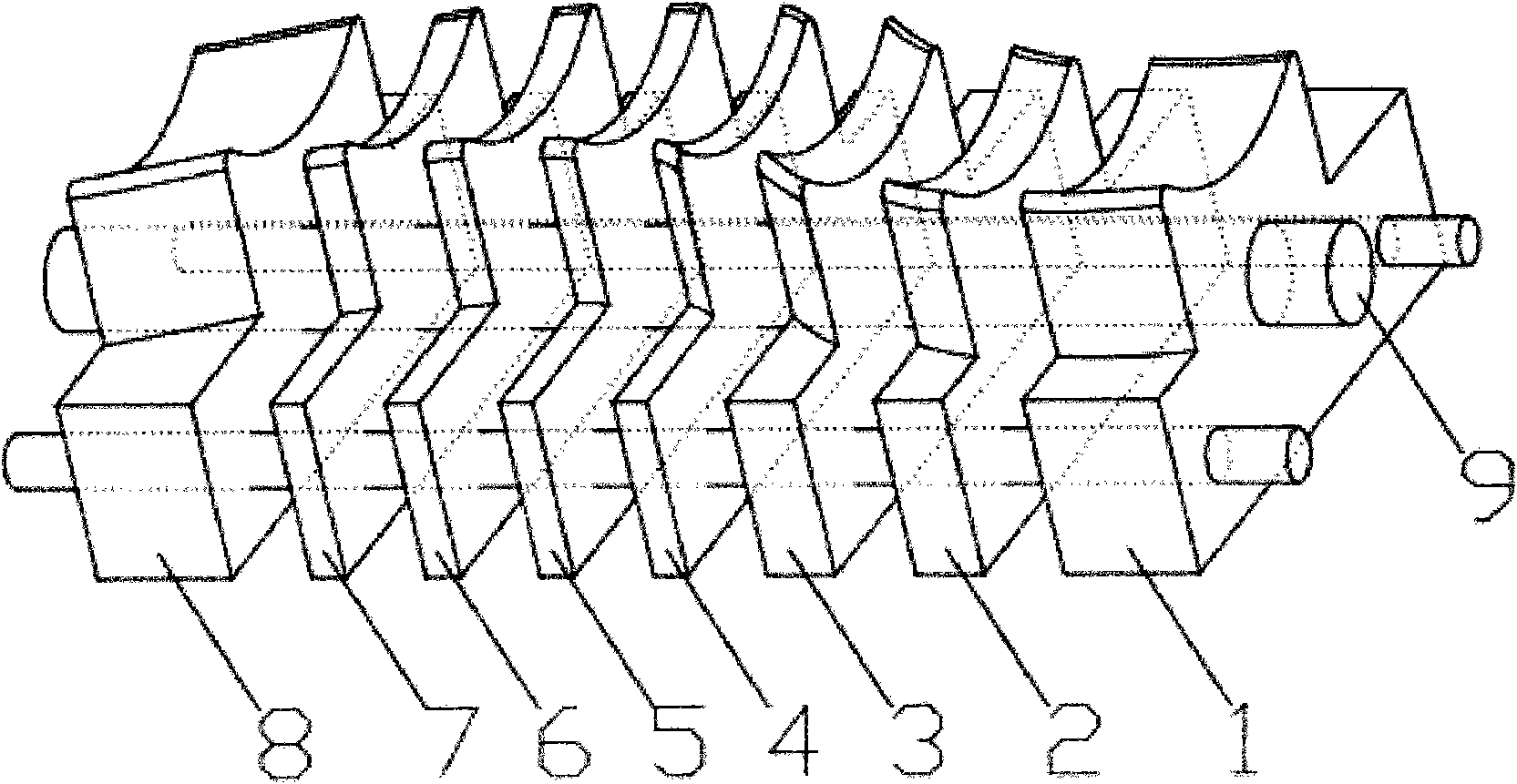

[0032] A rapid and high-precision manufacturing method for layered modular molds based on laser combined processing technology proposed by the present invention makes full use of modern CAD, realizes fully digitally driven layered modular mold CAD and CAM, and breaks through the traditional mold structure bondage. In the following, the present invention will be further described in detail in conjunction with the accompanying drawings and the inventors give embodiments according to the technical solution of the present invention.

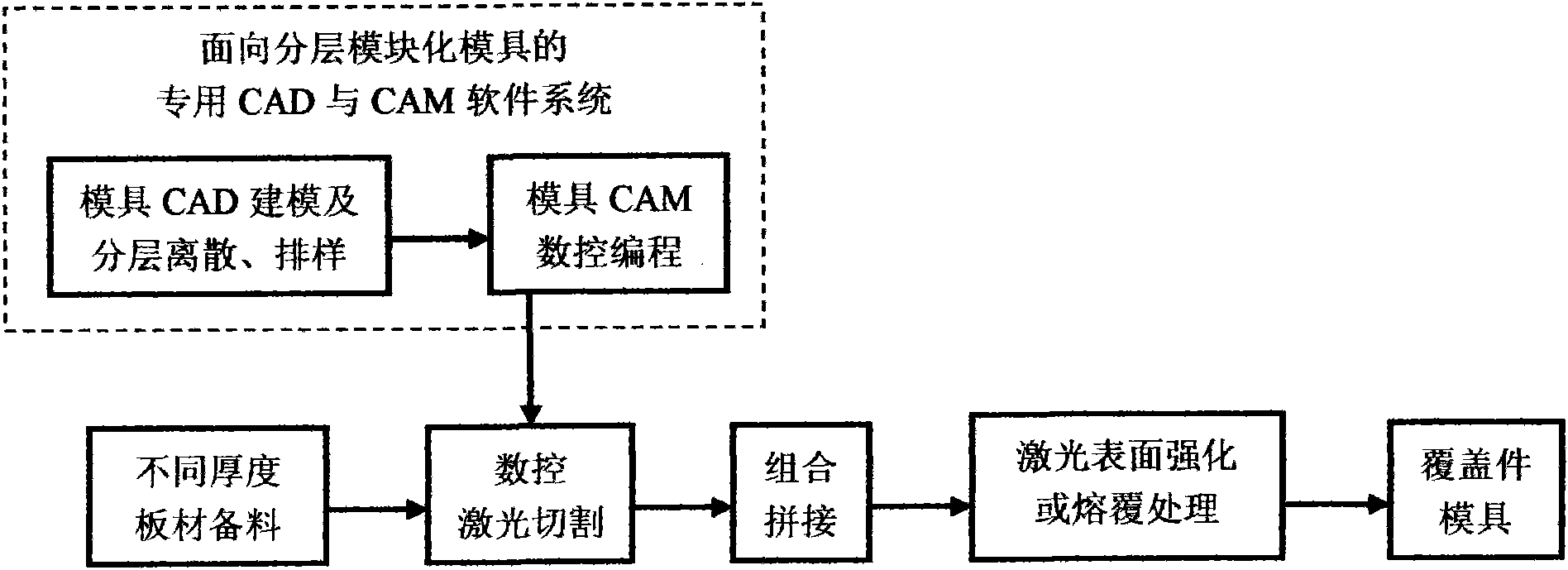

[0033] 1) The technical approach of mold manufacturing

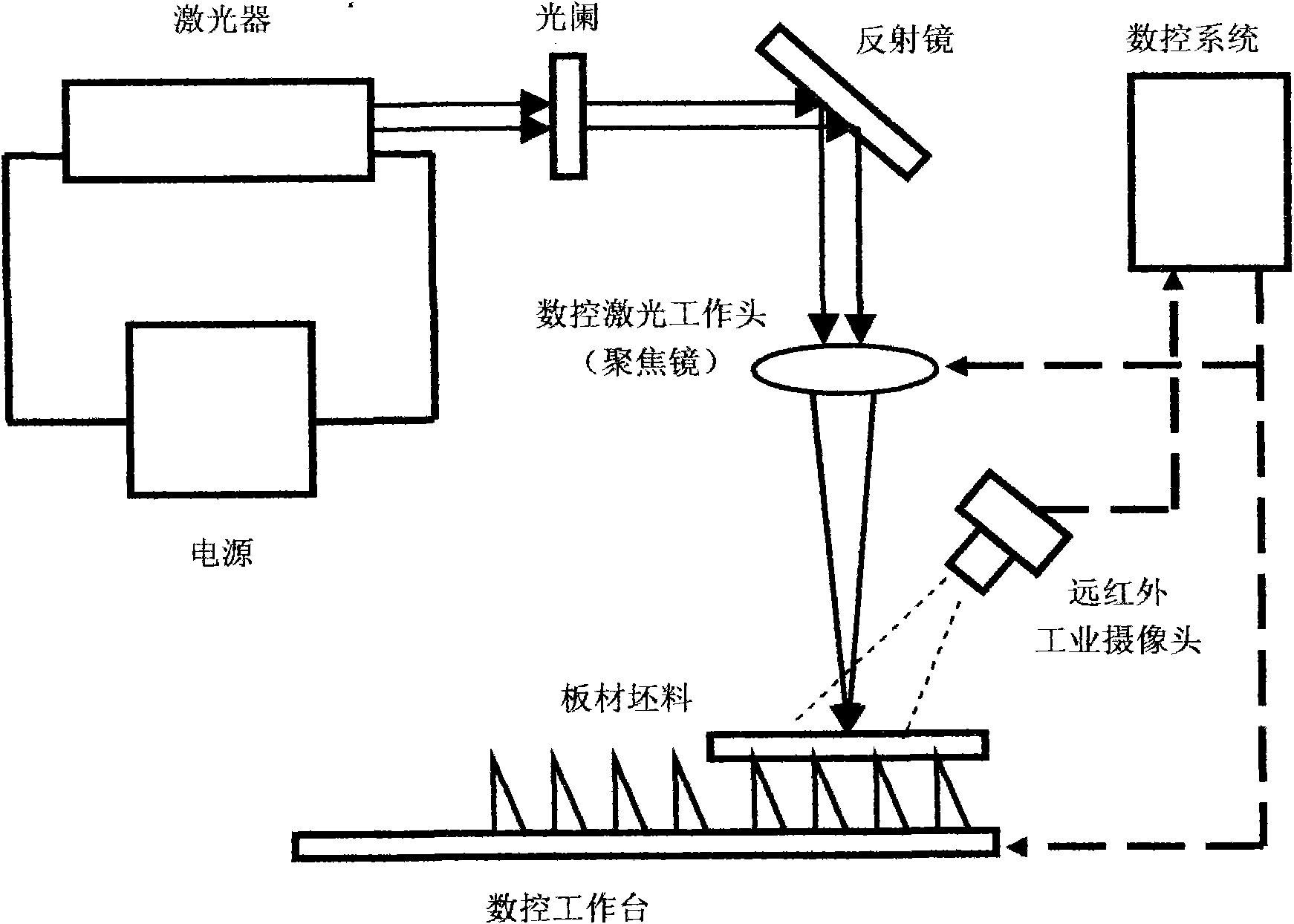

[0034] see figure 1 , the main technical approach of using the present invention to carry out rapid and high-precision manufacturing of stamping dies is: ①Use the special-purpose CAD and CAM software system oriented to the layered modular die structure provided by the present invention to carry out layered discrete processing, blanking and layout of the dies and NC programming; ② The blank is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com