Veneers for walls, retaining walls and the like

a technology of veneration and retaining walls, applied in the field of veneration panels, can solve the problems of retaining walls, affecting the appearance of retaining walls, and affecting the appearance of retaining walls, and achieve the effect of improving the appearance of the front face and costing effectiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

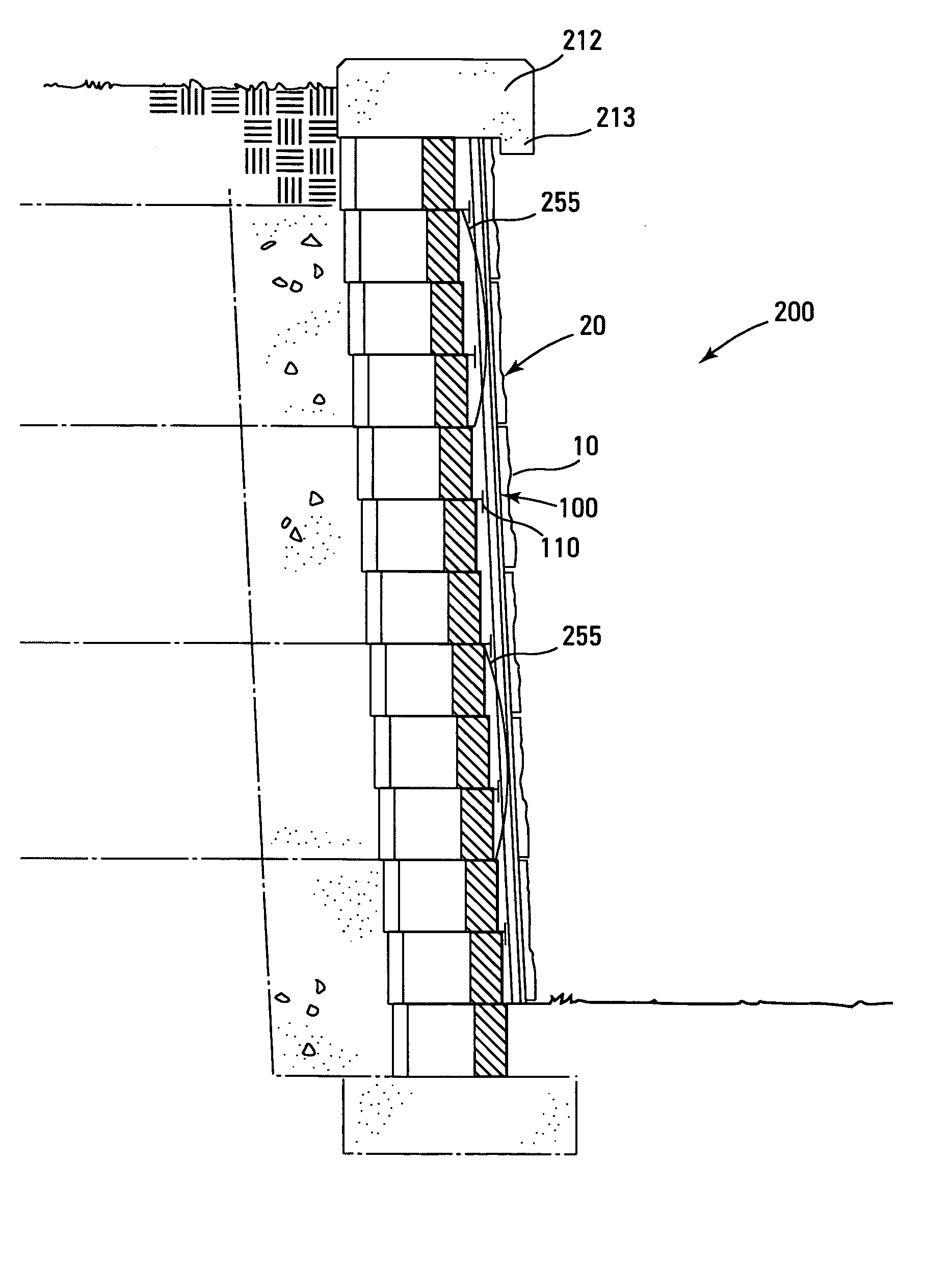

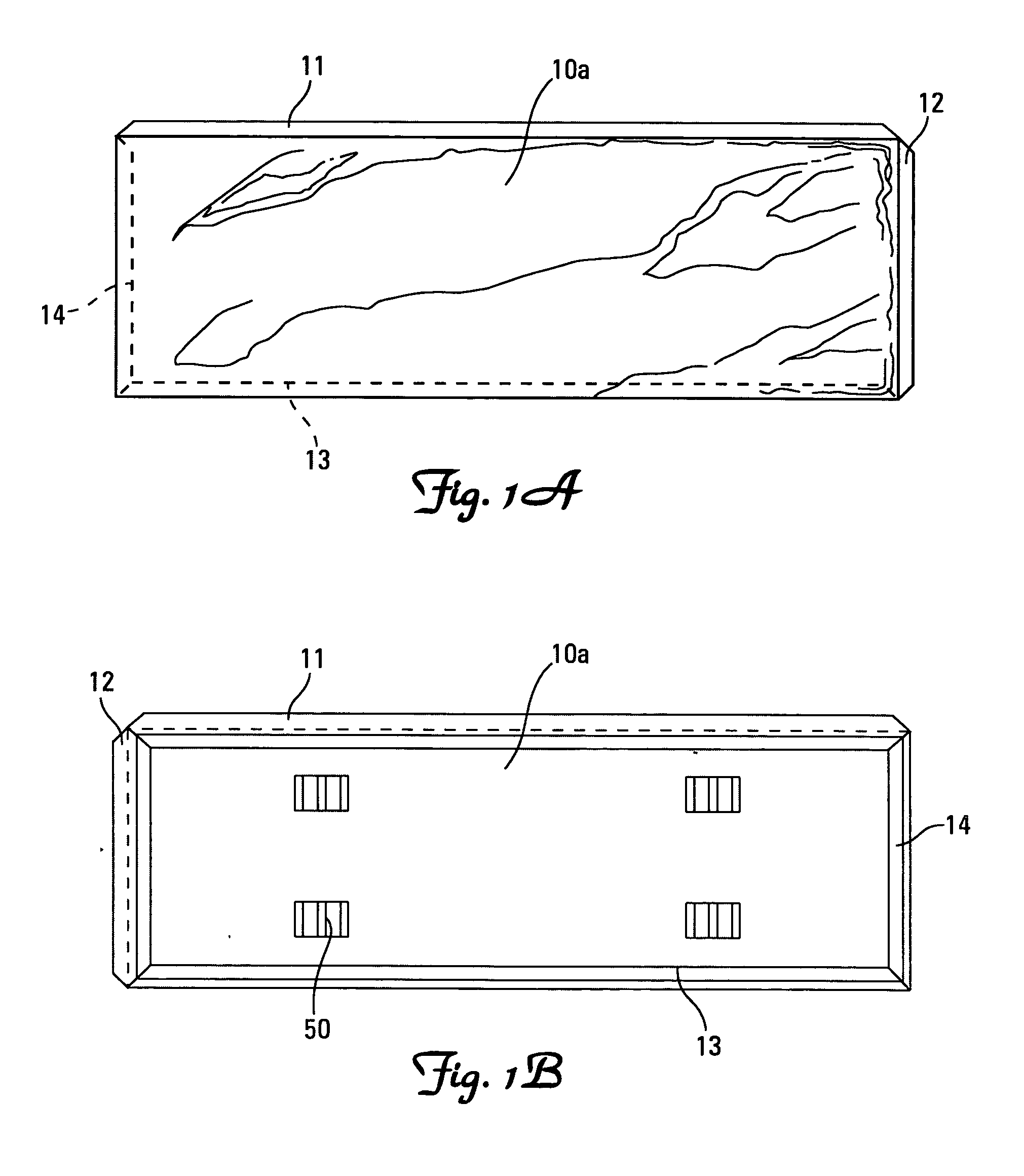

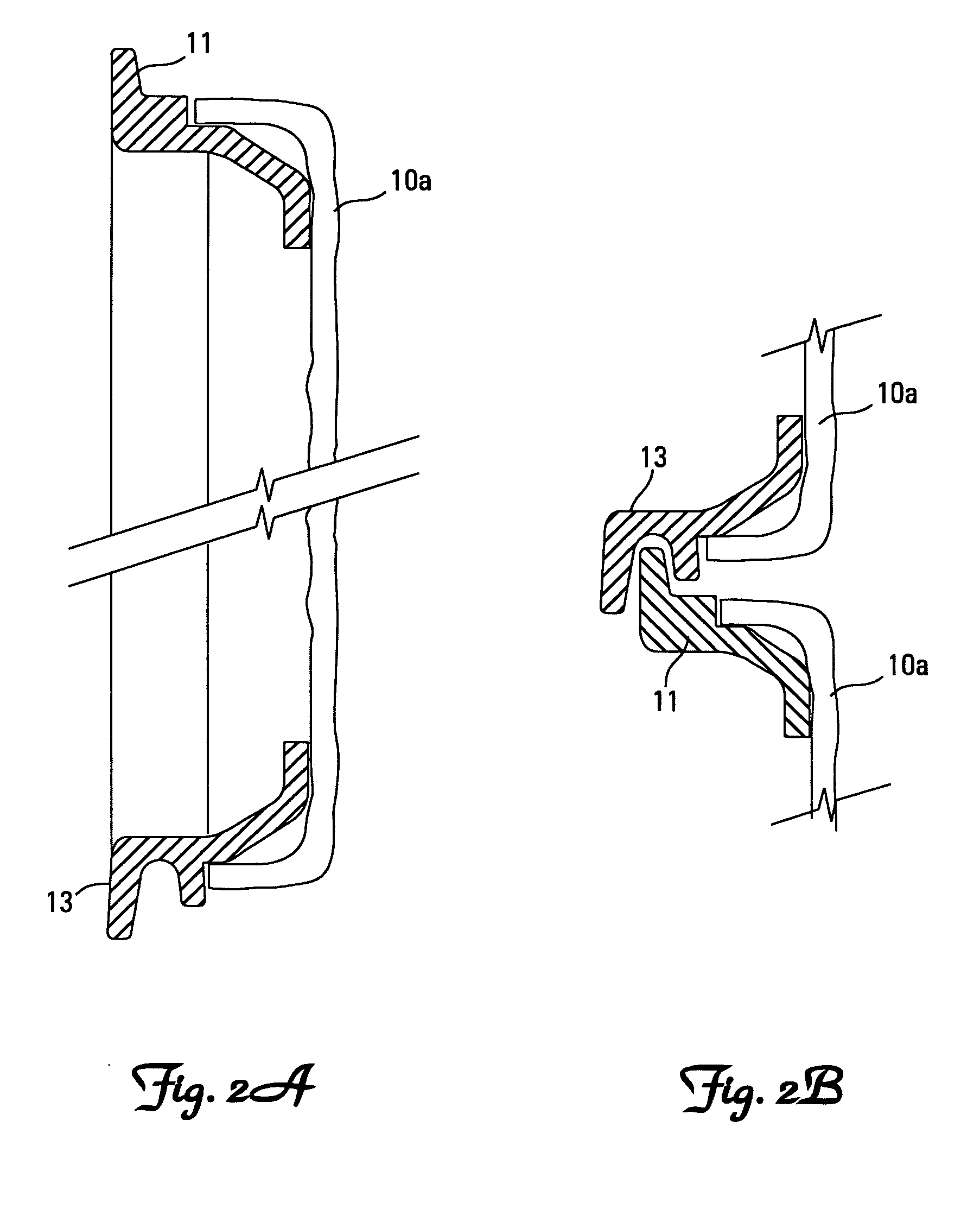

[0032] In this application, wall refers to structures comprising natural stone, poured concrete, precast panels, masonry, landscape timbers or railroad ties, and retaining wall blocks. Panels having a desired appearance are used as a veneer by attaching the panels to the exposed surfaces of a wall.

[0033] In a preferred embodiment, the panels of this invention are used with retaining walls, and in a most preferred embodiment, the retaining walls comprise blocks. The blocks are made of a rugged, weather resistant material, preferably (and typically) zero-slump molded concrete. Other suitable materials include plastic, reinforced fibers, wood, metal and stone. The blocks may have various shapes and characteristics, as known in the art, and may be stacked one upon the other to provide a straight wall, and also may be stacked so that they are angled from vertical. As known in the art, the blocks may be connected to each other by a pin attachment system, or the blocks may be provided wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sizes | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com