Stereoscopic magical-color ceramic product and preparation method thereof

A technology of illusion and ceramics, which is applied in the production field of powder cloth three-dimensional illusion ceramic products, which can solve the problems of not having three-dimensional illusion and three-dimensional effect, and achieve the effect of clear and rich patterns and strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

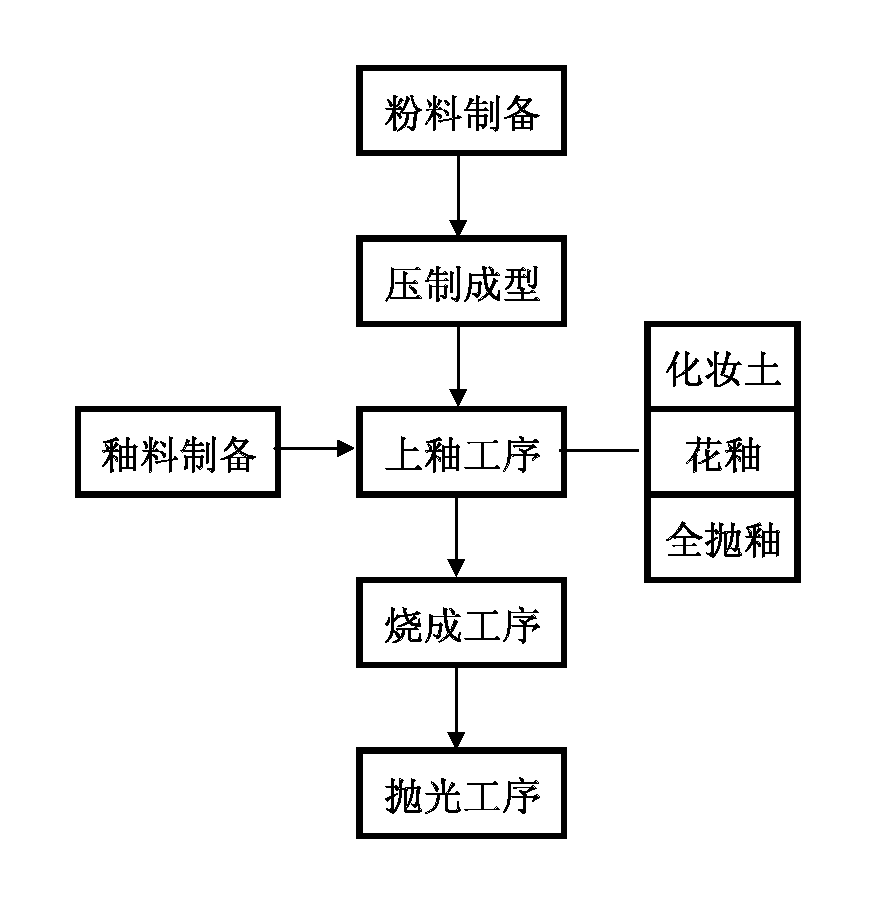

[0020] Here, the invention provides a method for preparing a three-dimensional illusion ceramic product. see figure 1 , which includes conventional powder preparation process, pressing process, glazing process, firing process and polishing process.

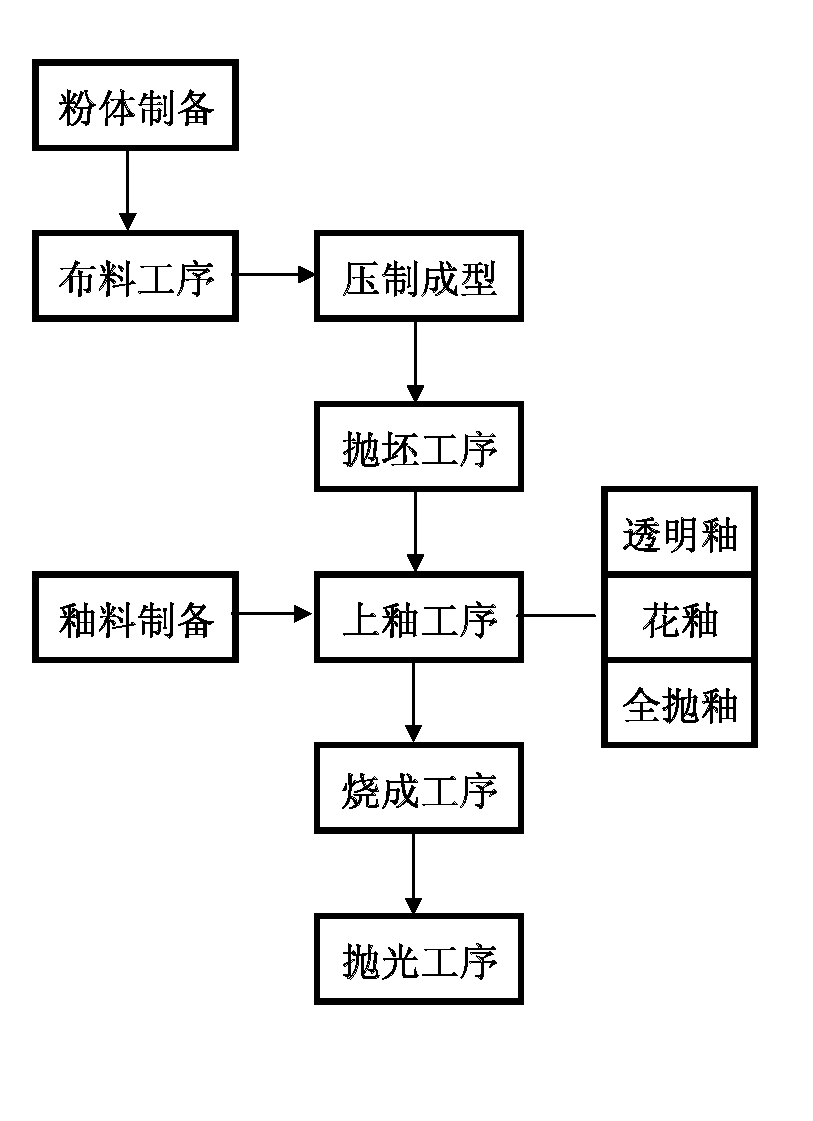

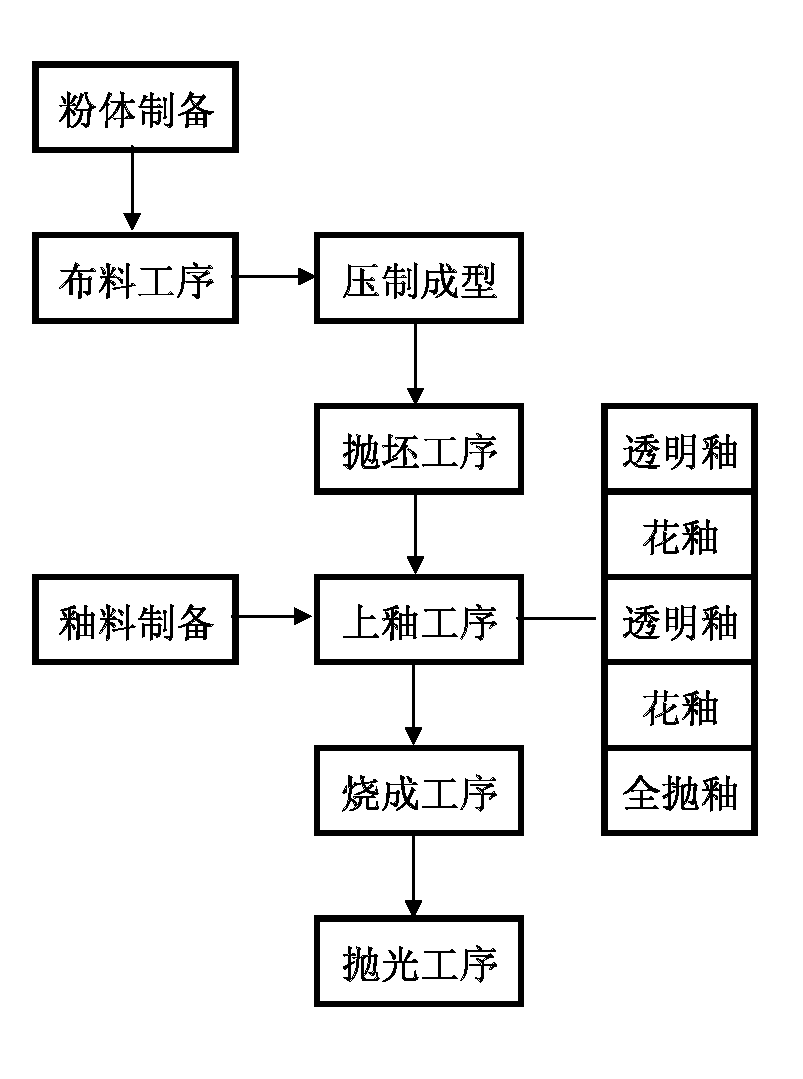

[0021] see figure 2 and image 3 , the present invention also includes cloth process. It can be primary cloth or secondary cloth. The secondary fabric is to divide the base material and the fabric twice, wherein the powder with different colors and different textures is used as the fabric on the surface of the adobe to distribute the designed pattern through the powder multi-tube fabric equipment. The fabric used in the surface layer of the adobe contains at least two or more powders of different colors. Whether it is primary fabric or secondary fabric, multi-tube fabric can be used, and surface layer powders of different colors are dropped into the grid of the material truck through different material tubes as the fabric la...

Embodiment 1

[0036] Using a powder dispenser, different types of powder are laid out in line patterns according to the design requirements. After being pressed and dried by a press, the surface of the dried billet is treated by a throwing machine. The depth of the throwing is 0.3mm, and a fine powder pattern is obtained. Dry billets. Spray a layer of specific gravity of 1.28g / cm on the surface of the dry billet 3 transparent glaze, the amount of glaze is 220g / m 2 , and then print and decorate through a roller printing machine, superimposing richer roller patterns to make the brick surface pattern more full. Finally, the full-polishing transparent glaze is used for screen printing, and the final product is obtained after firing once in the kiln for polishing and edging.

Embodiment 2

[0038] In the implementation case 1, the adobe after the printing decoration is sprayed with a layer of specific gravity of 1.35g / cm 3 transparent glaze, the amount of glaze is 280g / m 2 , transported to a ceramic inkjet printer through a belt for inkjet printing decoration, and the subsequent process is the same as Case 1.

[0039] The beneficial effects of the invention are: the product prepared by the production method combines the characteristics of rough powder pattern, real texture, rich and delicate antique brick pattern, and the like. By applying transparent glaze and printing repeatedly, a multi-level three-dimensional decorative effect can be presented. The product pattern is clear and rich, the texture is fine like natural stone, with clear layers and strong three-dimensional effect. The overall paving effect is better than natural stone, and has a very good market promotion prospect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com