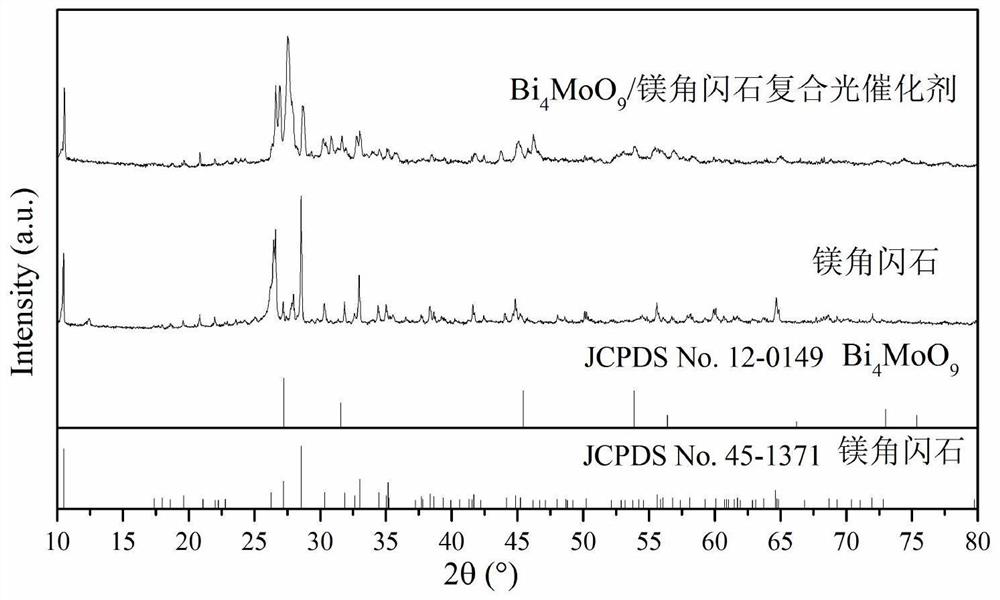

a bi 4 moo 9 Preparation method of amphibole composite photocatalyst

A technology of amphibole and composite light, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc. It can solve the problems of poor natural sedimentation performance and achieve high solubility , easy to wash, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) 4.85g Bi (NO 3 ) 3 ·5H 2 Mix O and 140mL of glycerol, stir and dissolve at room temperature with ultrasonic (ultrasonic power 60W) for 20min, and continue to stir in a water bath at 20°C for use, after obtaining mixed clear solution A;

[0026] (2) Disperse 9.7g of magnesium amphibole (particle size 2000 mesh) ultrasonically (ultrasonic power 100W) in 97mL of deionized water to obtain solution B;

[0027] (3) 0.485g (NH 4 ) 6 Mo 7 O 24 ·4H 2 O was dissolved in 136 mL of deionized water, and stood at room temperature for use to obtain mixed solution C;

[0028] (4) 3.56g NH 4 HCO 3 Dissolve in 72 mL of deionized water, and stand at room temperature for use to obtain mixed solution D;

[0029] (5) adding the solution B obtained in step (2) into the mixed clear solution A obtained in step (1), and stirring in a water bath at 90° C. for 10 min to obtain mixed solution E;

[0030] (6) mixing solution C prepared in step (3) and solution D prepared in step (4) t...

Embodiment 2

[0033] (1) 5.82g Bi (NO 3 ) 3 ·5H 2 Mix O and 174mL of glycerol, stir and dissolve at room temperature with ultrasonic (ultrasonic power 60W) for 40min, and continue to stir in a water bath at 30°C for use, after obtaining mixed clear solution A;

[0034](2) Disperse 8.31 g of magnesia amphibole (particle size 6000 mesh) ultrasonically (ultrasonic power 100 W) in 124 mL of deionized water to obtain solution B;

[0035] (3) 0.53g (NH 4 ) 6 Mo 7 O 24 ·4H 2 O was dissolved in 159 mL of deionized water, and stood at room temperature for use to obtain mixed solution C;

[0036] (4) 4.24g NH 4 HCO 3 Dissolve in 95 mL of deionized water, let stand at room temperature for use, and obtain mixed solution D;

[0037] (5) Add the solution B obtained in step (2) to the mixed clear solution A obtained in step (1), and stir in a water bath at 90°C for 30 min to obtain mixed solution E

[0038] (6) mixing solution C prepared in step (3) and solution D prepared in step (4) to obtain...

Embodiment 3

[0041] (1) 6.79g Bi (NO 3 ) 3 ·5H 2 Mix O and 190 mL of glycerol, and at room temperature, ultrasonically (ultrasonic power 100W) was stirred and dissolved for 30 min, and at 30 ° C, the water bath continued to stir for use, and after obtaining the mixed clear solution A;

[0042] (2) Disperse 13.58 g of magnesia amphibole (particle size 2000 mesh) ultrasonically (ultrasonic power 60 W) in 136 mL of deionized water to obtain solution B;

[0043] (3) 0.645g (NH 4 ) 6 Mo 7 O 24 ·4H 2 O was dissolved in 182 mL of deionized water, and stood at room temperature for use to obtain mixed solution C;

[0044] (4) 4.5g NH 4 HCO 3 Dissolve in 112 mL of deionized water, let stand at room temperature for use, and obtain mixed solution D;

[0045] (5) adding the solution B obtained in step (2) into the mixed clear solution A obtained in step (1), and stirring in a water bath at 90° C. for 30 min to obtain mixed solution E;

[0046] (6) mixing solution C prepared in step (3) and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com