Novel microcrystalline glass ceramic composite board and preparation method thereof

A glass-ceramic, glass-ceramic technology, applied in the field of building materials, can solve the problems affecting the market competitiveness and sales of products, unfavorable market promotion of high-end products, expensive zinc oxide, etc. The effect of long firing cycle and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A new type of glass-ceramic composite board, which is made of glass-ceramic and green ceramic board, wherein:

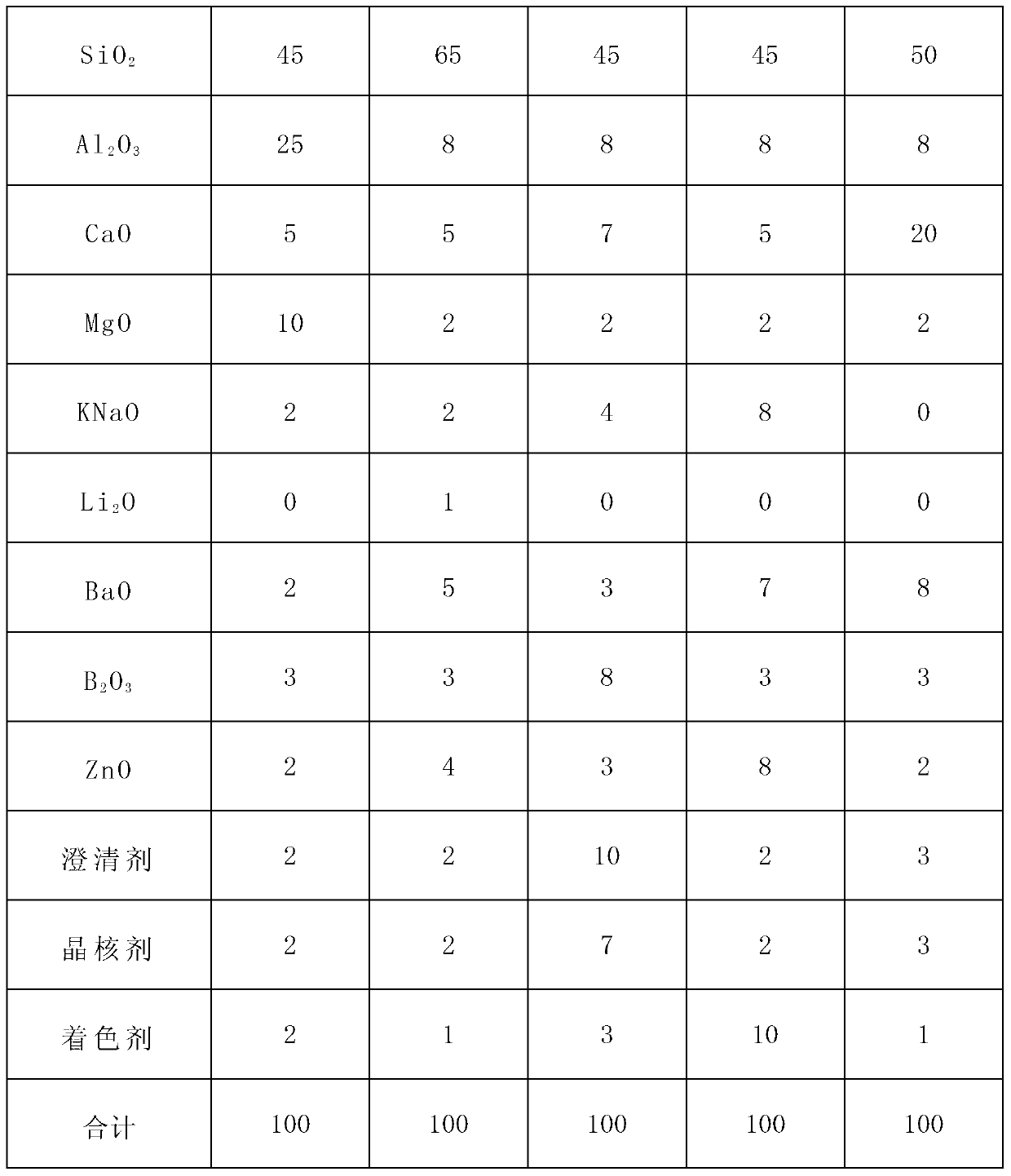

[0027] Glass-ceramics: Quartz, potassium feldspar, albite, calcite, talc, dolomite, alumina, zinc oxide, boric acid, borax, barium carbonate, soda ash, lithium minerals, etc. Crystal nucleating agent and coloring agent are made according to Table 1 formula 1~5;

[0028] Table 1 Glass-ceramic formulation table (parts by weight)

[0029]

[0030]

[0031] The lithium mineral is lepidolite, spodumene, hectorite or hectorite. The clarifying agent is preferably fluorite; the crystal nucleating agent is preferably zircon; the coloring agent is preferably metal oxide.

[0032] Ceramic plate green body: kaolin, china clay, clay, potassium feldspar, albite, quartz, talc and other raw materials, as well as water reducing agent and green body strengthening agent, are made according to formulas 1 to 5 in Table 2.

[0033] Table 2 Ceramic plate green body formula ...

Embodiment 2

[0037] The preparation method of novel glass-ceramic composite board comprises the following steps:

[0038] (1) Preparation of glass-ceramic: Mix the components of the glass-ceramic formula (choose one from formulas 1 to 5 in Table 1 in Example 1) evenly, melt at 1450°C to form a melt, and then water Quenching, drying, crushing, and sieving into 6-purpose glass-ceramic pellets for use.

[0039] (2) Preparation of the ceramic plate green body: Mix the components of the ceramic plate green body formula (choose one from formula 1 to 5 in Table 2 in Example 1) evenly, finely crush by ball mill, spray dry powder, automatic hydraulic press Forming and kiln drying to obtain a ceramic plate green body, and then apply a layer of surface glaze with a thickness of 0.3mm for use.

[0040] (3) Composite the glass-ceramics and the ceramic plate green body: evenly sprinkle the glass-ceramic granules obtained in step (1) on the surface of the glazed ceramic plate green body obtained in step...

Embodiment 3

[0042] A method for preparing a novel glass-ceramic composite plate, comprising the following steps:

[0043] (1) Preparation of glass-ceramic: Mix the components of the glass-ceramic formula (choose one from formulas 1 to 5 in Table 1 in Example 1) evenly, melt at 1520°C to form a melt, and then water Quenching, drying, crushing, and sieving into 120-mesh glass-ceramic pellets for use.

[0044] (2) Preparation of the ceramic plate green body: Mix the components of the ceramic plate green body formula (choose one from formula 1 to 5 in Table 2 in Example 1) evenly, finely crush by ball mill, spray dry powder, automatic hydraulic press Forming and kiln drying to obtain a ceramic plate green body, and then apply a layer of surface glaze with a thickness of 0.5mm for use.

[0045](3) Composite the glass-ceramics and the ceramic plate green body: evenly sprinkle the glass-ceramic granules obtained in step (1) on the surface of the glazed ceramic plate green body obtained in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com