Organic waste gas treater utilizing attapulgite adsorption and superparamagnetic field magnetolysis

A technology of organic waste gas and attapulgite, which is applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of high processing cost, high maintenance cost, large power consumption, etc., and achieve high exhaust gas purification rate and maintenance cost. Low, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Now the present invention is further described in conjunction with description of drawings and embodiments:

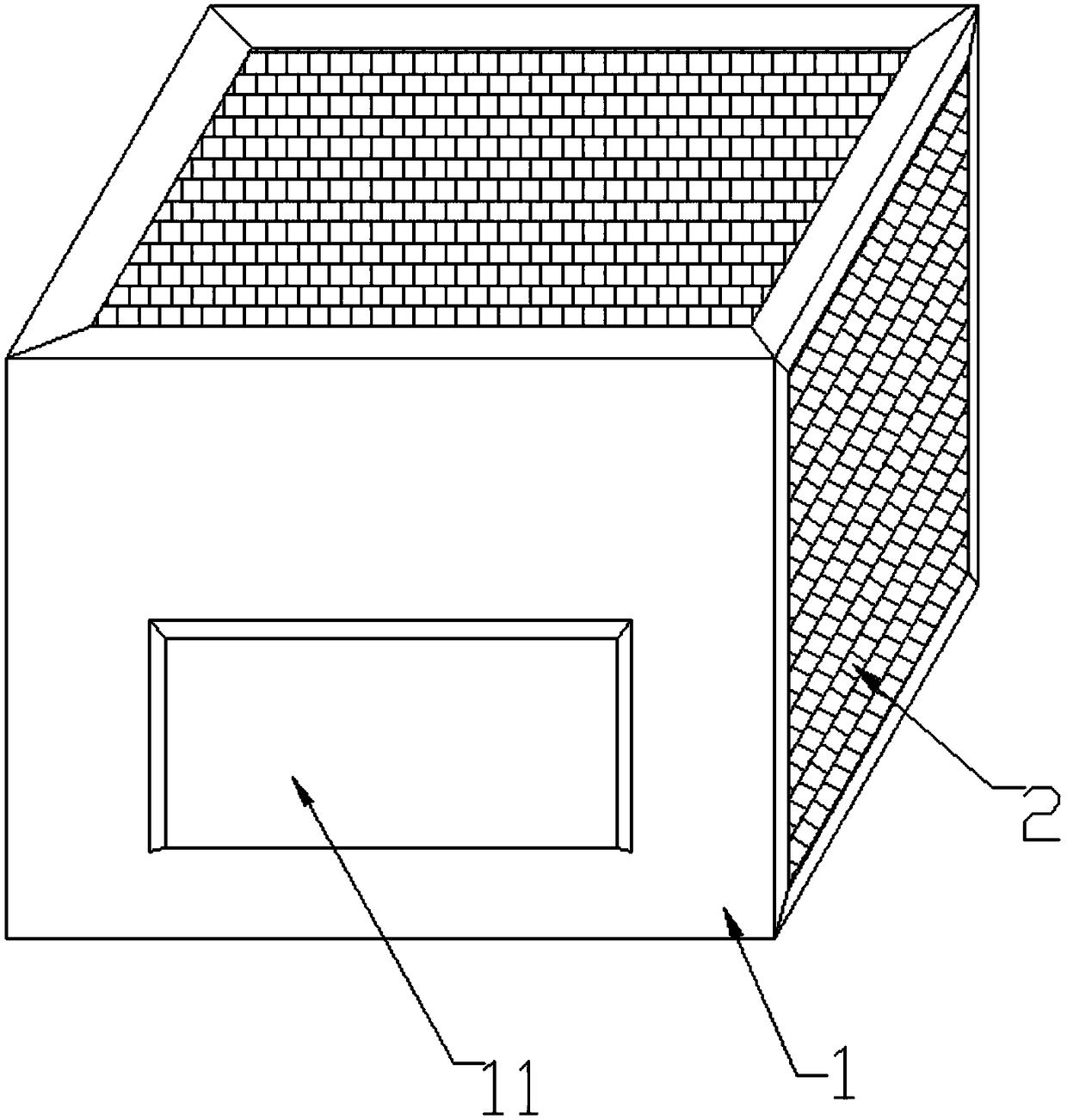

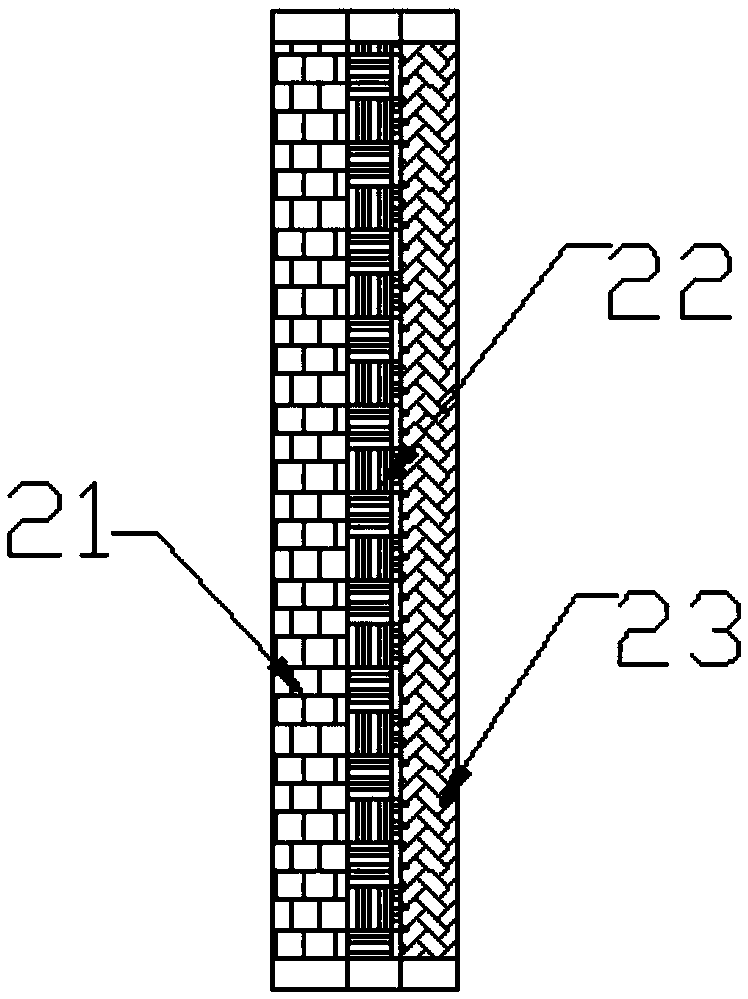

[0037] refer to Figure 1-3 , an organic waste gas processor utilizing attapulgite adsorption and superparamagnetic field magnetolysis, comprising a processor 1 and a fan inside the processor; one side of the processor 1 is provided with an air outlet 11 and at least one side is provided with an inlet Wind surface 2, the air inlet surface is provided with attapulgite molecular sieve 21, modified activated carbon 22 and superparamagnetic field magnetolysis plate 23 from outside to inside;

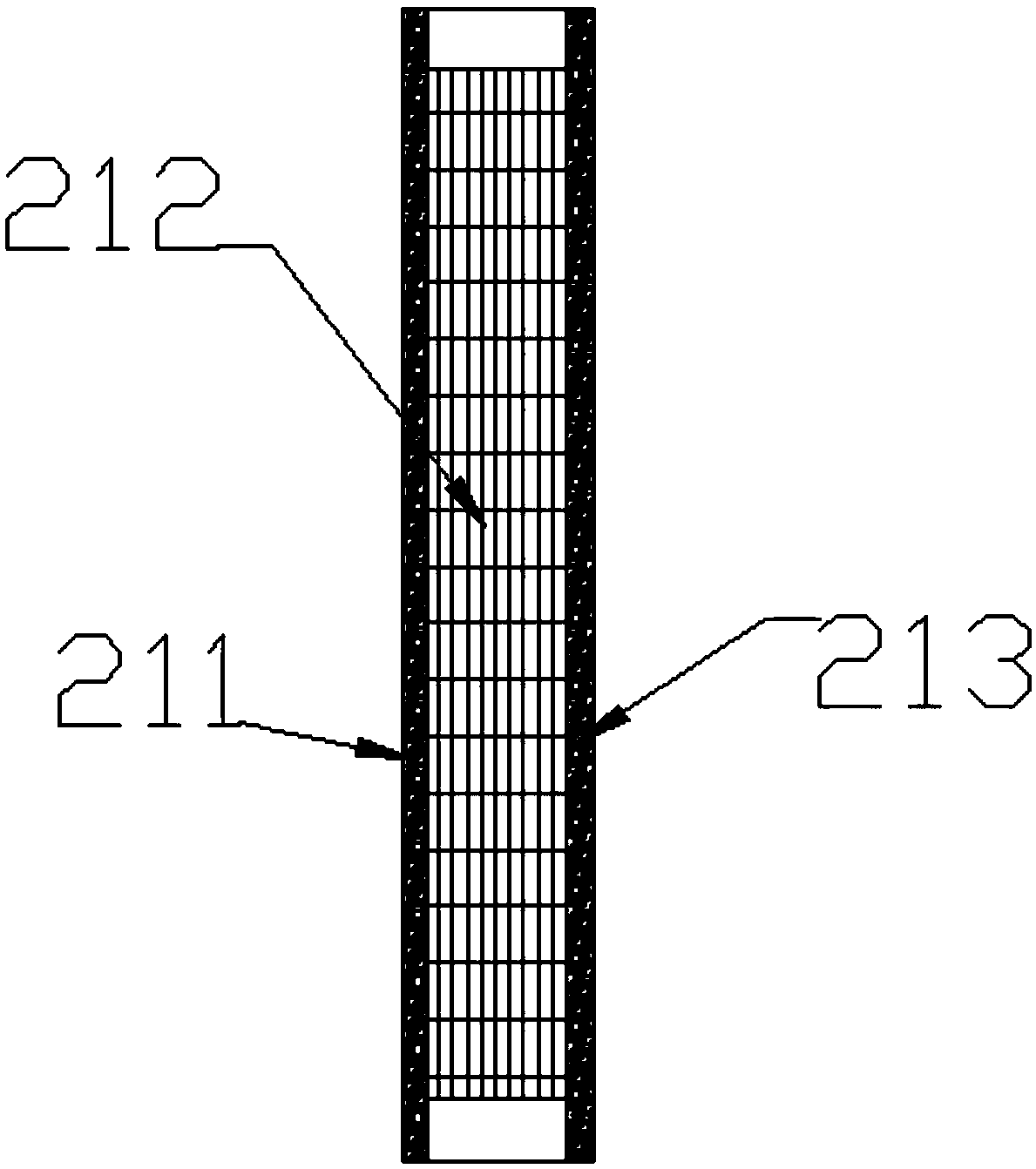

[0038] The attapulgite molecular sieve has a three-layer structure, including a front fine mesh 211, a middle honeycomb flow layer 212 and a rear fine mesh 213. The honeycomb flow layer is filled with attapulgite particles, and consists of the front fine mesh and the rear fine mesh. Layers of fine mesh wrapping;

[0039] The attapulgite molecular particles are made by pulver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com