Novel microcrystal glass ceramic composite board and preparation method thereof

A glass-ceramic, glass-ceramic technology, applied in the field of decorative building materials, can solve problems affecting product competitiveness and sales, and achieve the effects of low price, low cost and wide distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A new type of glass-ceramic composite plate, which is composed of glass-ceramic and ceramic plate blank, is characterized in that:

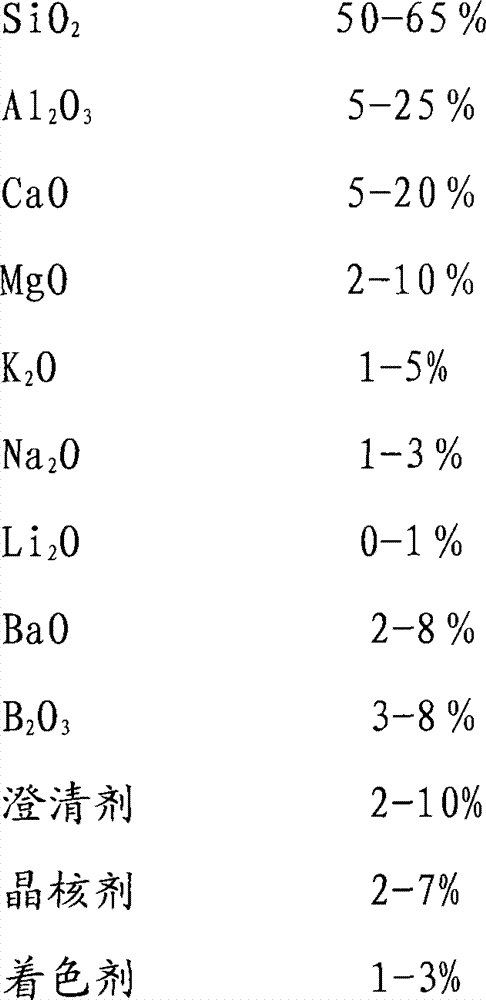

[0023] Glass-ceramic consists of the following components by weight:

[0024]

[0025] The clarifying agent is fluorite, and the crystal nucleating agent is zircon.

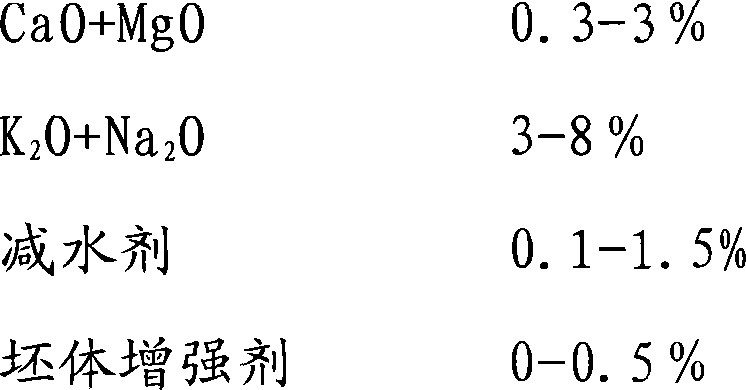

[0026] The ceramic slab green body is composed of the following components by weight:

[0027]

[0028]

[0029] The method for preparing the novel glass-ceramic composite plate is characterized in that:

[0030] a. Preparation of glass-ceramic:

[0031] Quartz, potassium feldspar, albite, calcite, talc, dolomite, barium carbonate, sodium carbonate, potassium carbonate, boric acid, borax and clarifying agents, nucleating agents and or without The mixture of colorants is mixed evenly and sent to the glass kiln for melting. The melting temperature is 1420°-1520°C. The melted melt is water-quenched, dried, screened, and broken into crystallites smaller than 10 mm wit...

Embodiment 2

[0036] A new type of glass-ceramic composite plate, which is composed of glass-ceramic and ceramic plate blank, is characterized in that:

[0037] Glass-ceramic consists of the following components by weight:

[0038]

[0039]

[0040] The clarifying agent is fluorite, and the crystal nucleating agent is zircon.

[0041] The ceramic slab green body is composed of the following components by weight:

[0042]

[0043] The preparation method of the novel glass-ceramic composite plate is the same as that of the first embodiment.

[0044] The present invention uses CaO and MgO as raw materials, which are widely distributed and low in price, and at the same time avoid using expensive ZnO as raw materials, so that the cost is low, and at the same time, CaO-MgO-Al is used. 2 O 3 -SiO 2 The glass-ceramic of the system makes it low cost and can achieve the same high surface tension and low viscosity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com