Method for preparing stony glazed vessel by using ophiolite

A vessel and stone technology, applied in the field of silicate materials and ceramics, can solve the problems of dust and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

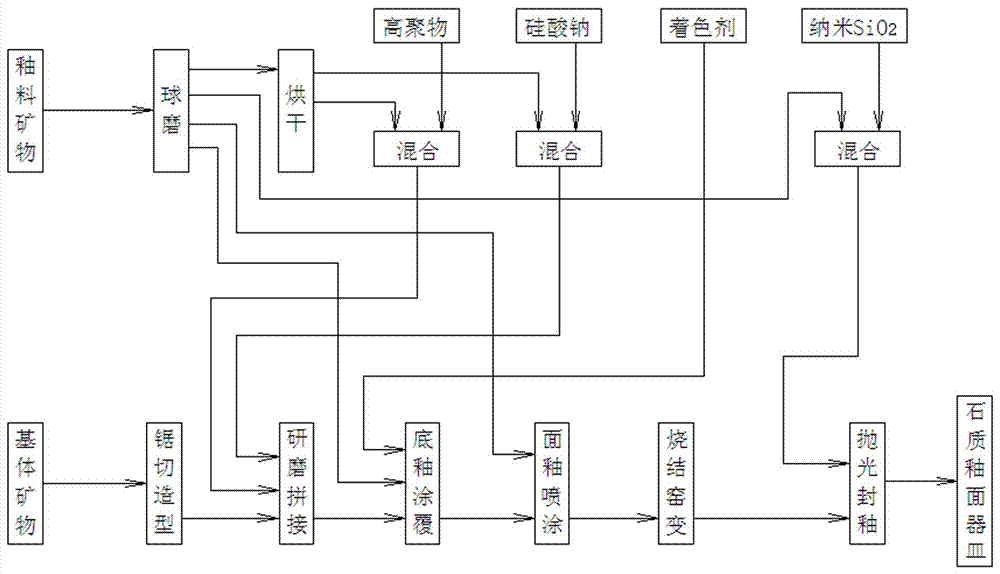

[0031] Wutaishan Tongqiangou olivine, serpentine, amphibolite and metadiabase minerals are used as matrix minerals. It is suitable to use wire saw and expansion cracking mining technology during mining. After sawing, grinding, splicing, bottom glaze coating, The basic technological process of surface glaze spraying, sintering kiln transformation, polishing and sealing glaze, preparing square bucket-shaped vessels, and using glaze minerals to make raw glaze through ball milling and drying auxiliary processes to cooperate with bottom glaze coating and surface glaze spraying. Specific process such as figure 1 shown.

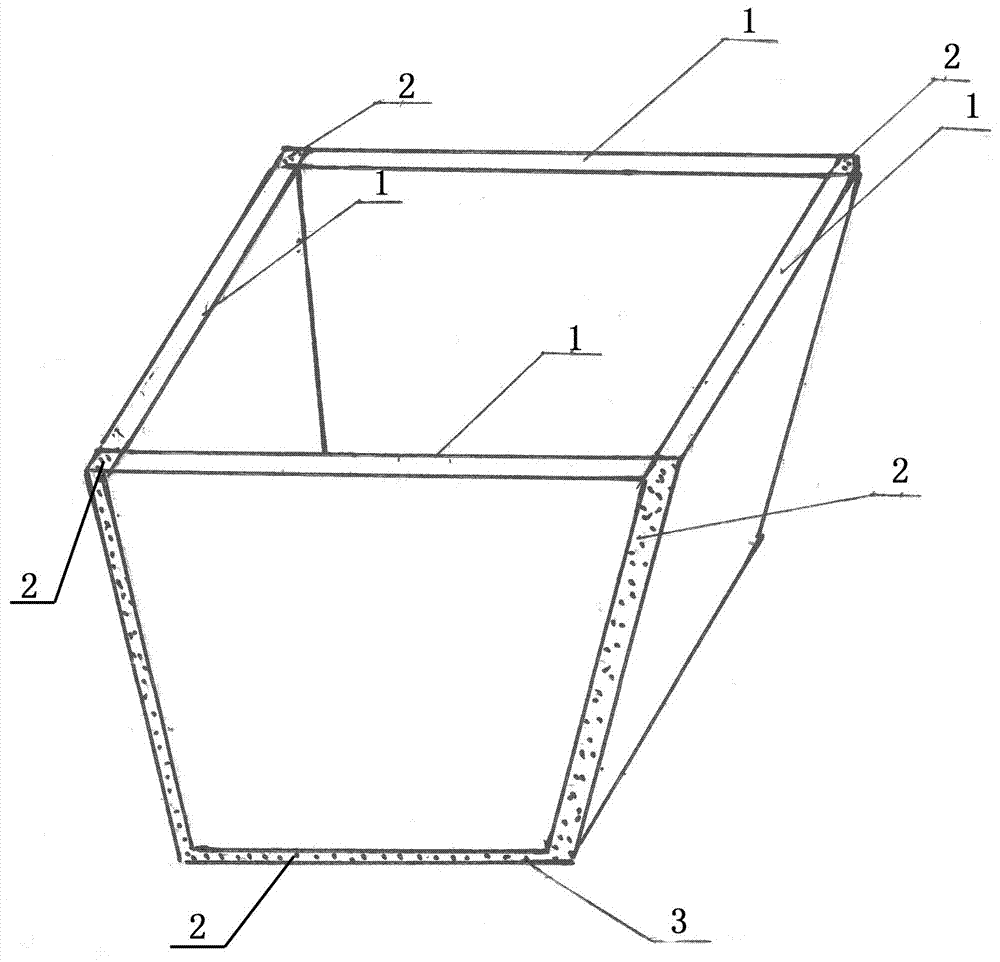

[0032] The preparation method of ophiolite glazed stoneware, the process steps are: sawing the shape is to use a circular saw to first saw the base mineral into a thin plate with a thickness of 12mm, and then cut it into 25cm in height, 45cm in width at the top and 45cm at the bottom Four trapezoidal plates with a width of 30cm, and a bottom plate with a side lengt...

Embodiment 2

[0034] The basic technological process of serpentinized dunite, serpentine, pyroxene, olivine and amphibolite as matrix minerals, sawing, grinding and splicing, bottom glaze coating, top glaze spraying, sintering kiln transformation and polishing , to prepare vases and round jars with circular arcs on the outside and hollow interiors, and the auxiliary process of ball milling the glaze minerals is inserted between the two processes of bottom glaze coating and top glaze spraying.

[0035] The preparation method of the ophiolite glazed stone vessel is as follows: the sawing and molding process is to use a circular saw to cut the matrix minerals mined by static blasting into square columns, and use a circular car equipped with a special cutter head to make A vase with a set pattern; Grinding and splicing is to grind the appearance and mouth of the vase, and the matrix cracks that appear in the process of turning and grinding can be bonded and solidified with polymer cement under d...

Embodiment 3

[0037] Using peridotite, diabase and serpentine as matrix minerals, the hexagonal bucket-shaped vessel was prepared through the basic technological process of sawing, grinding and splicing, bottom glaze coating, surface glaze spraying, sintering kiln transformation and polishing and sealing glaze, and used Glaze minerals are made into raw glaze and high-polymer clay through ball milling, drying and mixing processes.

[0038] The preparation method of ophiolite glazed stoneware, its process steps: sawing shape is to use the circular saw used in stone production to first saw the base mineral into 30mm thick rough board, and cut into 50cm high, the upper side Six trapezoidal plates with a width of 60cm and a lower side width of 45cm are also cut into a hexagonal bottom plate with a side length of 46cm; the grinding and splicing is to coarsely grind the two sides of each plate composed of seven plates. The six side plates lean on the six-cone model with a large bottom and a small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com