Beneficiation method for molybdenum-containing high-zinc complex magnesium silicate altered skarn type copper ore

A technology of magnesium silicate and ore dressing method, which is applied in the direction of chemical instruments and methods, flotation, wet separation, etc., can solve the problems of large damage, difficult floatability, poor product quality, etc., and simplify the pharmaceutical system , Guarantee the effect of high purity quality and recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

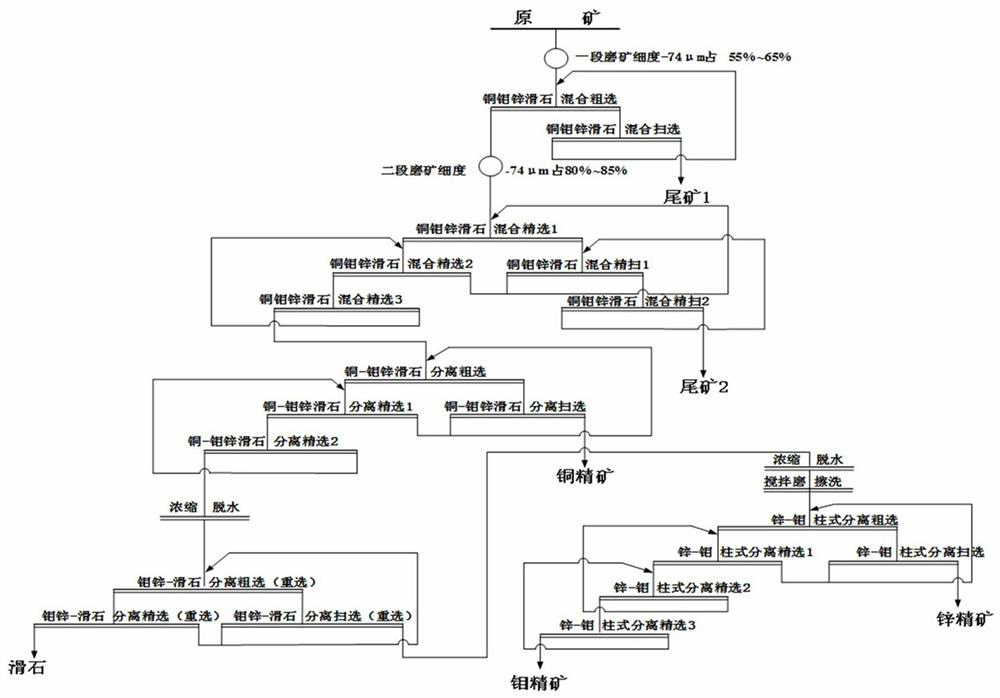

Method used

Image

Examples

Embodiment 1

[0058]A concentrator in Nianqing, Tibet, contains 0.59% copper, 0.015% molybdenum, 0.39% zinc, and 16.35% magnesium. The main metal minerals are sulfide minerals (chalcopyrite, chalcocite, copper blue, molybdenite and flash Zinc ore), magnesium silicate minerals are mainly talc and serpentine, talc and molybdenite have good natural buoyancy, affected by the inevitable ions of the pulp, sphalerite has excellent buoyancy, talc and various metals Minerals have very little difference in floatability and are difficult to separate. The above-mentioned ore samples are processed through the following process steps:

[0059] A. One-stage grinding: The crushed copper ore is subjected to one-stage grinding, and the grinding fineness is -74μm, accounting for 65%.

[0060] B. Copper-molybdenum-zinc talc mixed roughing: the first-stage grinding product is subjected to copper-molybdenum-zinc talc mixed roughing, and the process conditions for copper-molybdenum-zinc talc mixed roughing are ad...

Embodiment 2

[0068] A concentrator in Inner Mongolia contains 0.51% copper, 0.017% molybdenum, 0.31% zinc, and 15.19% magnesium. The main metal minerals are sulfide minerals (chalcopyrite, chalcopyrite, chalcopyrite, copper blue, molybdenite and sphalerite talc, talc and molybdenite have good natural buoyancy, affected by the inevitable ions in the pulp, sphalerite has excellent buoyancy, and the buoyancy between talc and various metal minerals The difference is very small and it is difficult to separate. The above-mentioned ore samples are processed through the following process steps:

[0069] A. One-stage grinding: The crushed copper ore is subjected to one-stage grinding, and the grinding fineness is -74μm, accounting for 60%.

[0070] B. Copper-molybdenum-zinc talc mixed roughing: the first-stage grinding product is mixed with copper-molybdenum-zinc talc roughing, the process condition of copper-molybdenum-zinc talc mixed roughing is to add calcium oxide 2500 g / ton, stir for 5 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com