Combined regulator for flotation of magnesian skarn type copper sulfide ore and application thereof

A technology for flotation of magnesium skarn and combined regulator, applied in flotation, solid separation, etc., can solve problems such as difficulties in flotation separation, scaling of pipes and cavities, dispersion of unfavorable mineral particles and flotation separation, etc., to achieve Improve the grade and recovery rate, eliminate adverse effects, and improve the effect of beneficiation indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

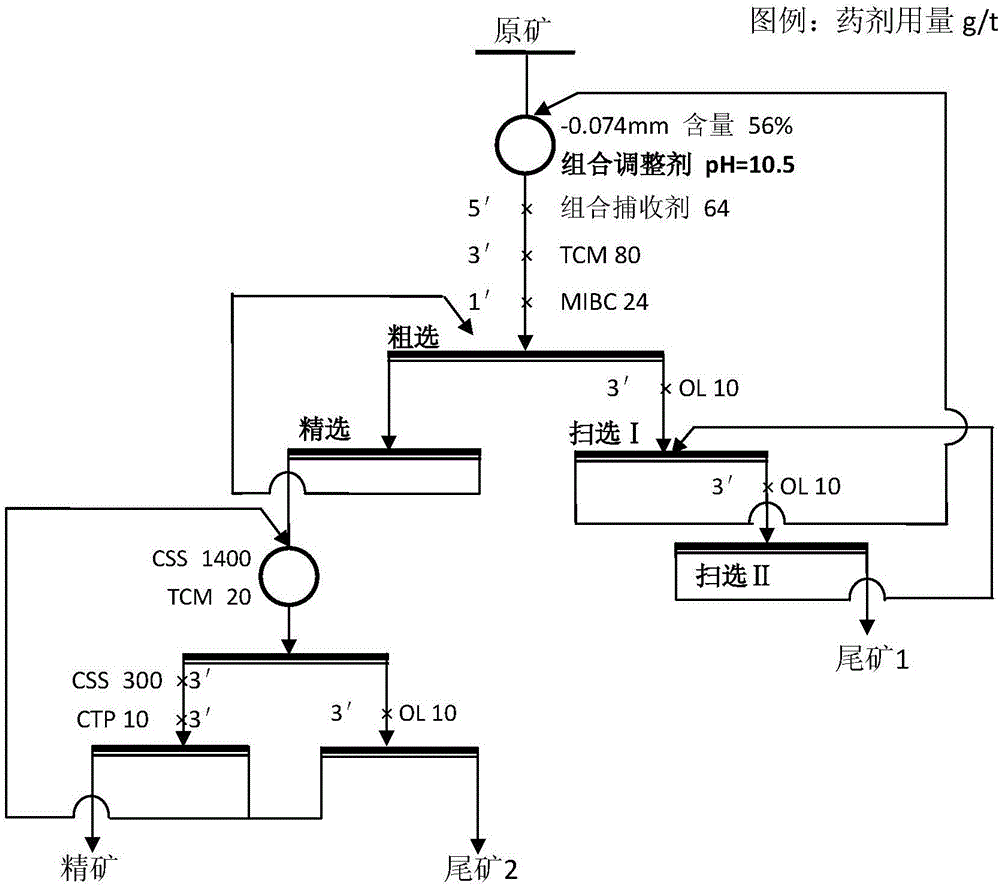

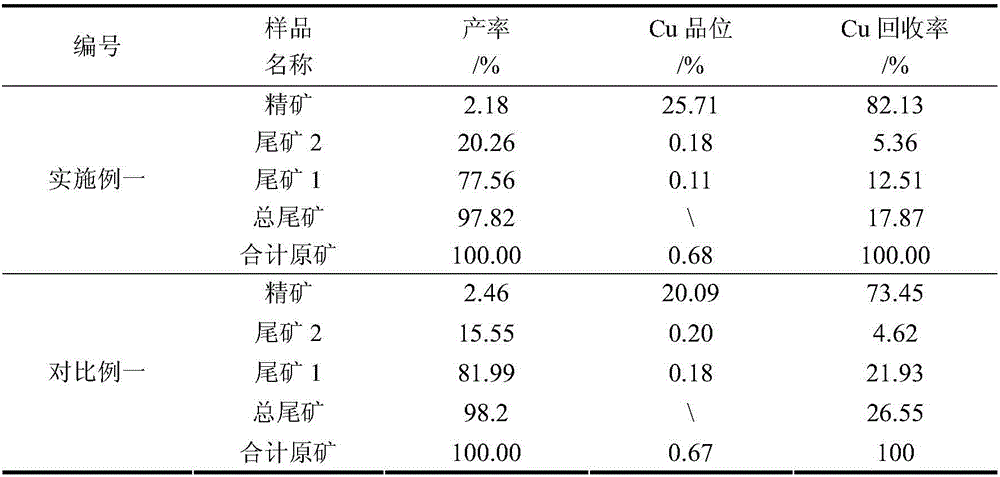

Embodiment 1

[0021] A large-scale copper sulfide ore produced in magnesium skarn in foreign countries, the raw ore copper grade is about 0.67%, the copper sulfide minerals in the raw ore are chalcopyrite, chalcocite and copper basket, and the gangue minerals are mainly pyrite and quartz , amphibole, mica, chlorite, talc, kaolinite and montmorillonite. Add combined regulator to the raw ore to adjust the pH value of the pulp to 10.5-11.0, the ratio of combined regulator is: 25:0.5:1, 56% is ground to -0.074mm; add combined collector 64 g / ton (OL, D Combination of ammonium black medicine and PAX, the proportion of the three is 3:3:1), adding inhibitor TCM 80 g / ton raw ore and foaming agent MIBC 24 g / ton raw ore, flotation to obtain roughing concentrate and roughing tailings mine. The tailings 1 are obtained after the roughing tailings are swept twice.

[0022] After the rough beneficiation concentrate goes through a blank beneficiation, a section of beneficiation concentrate is obtained. T...

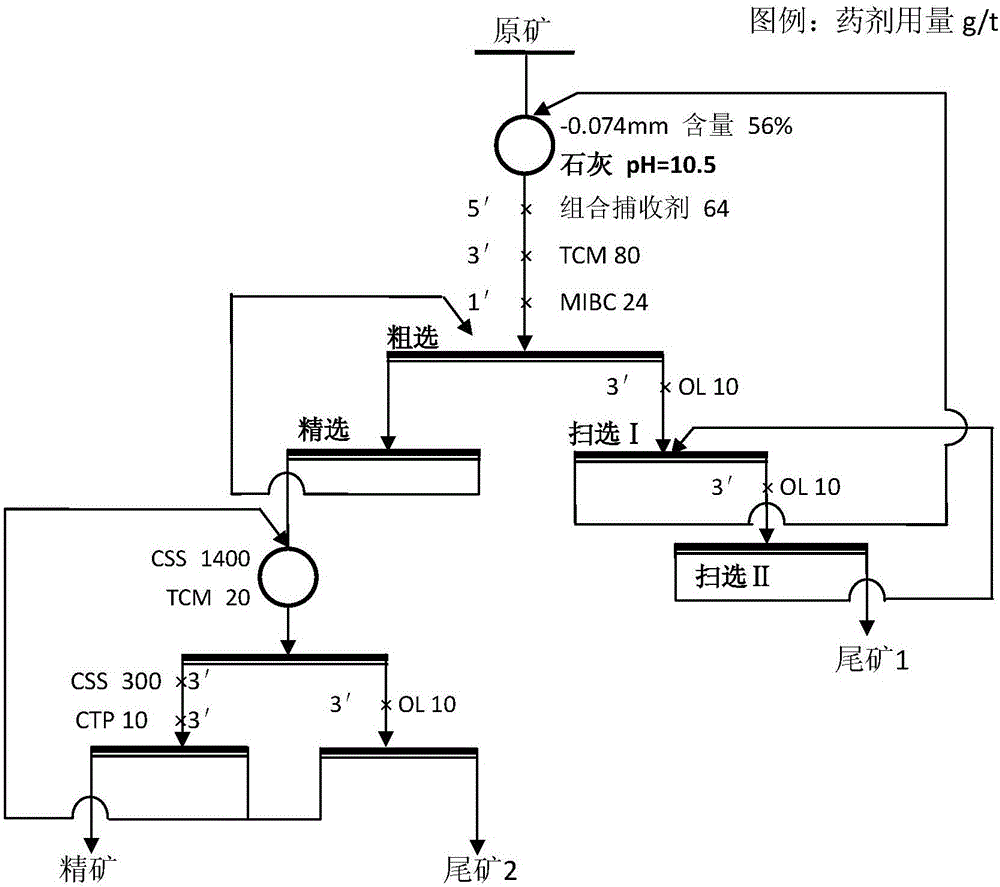

Embodiment 2

[0030] A large-scale copper sulfide ore produced in magnesia skarn abroad has a copper grade of about 0.53%. The copper sulfide mineral in the ore is chalcopyrite, and the gangue minerals are mainly pyrite, quartz, mica, amphibole, stone, chlorite, talc. Add a combination regulator to the raw ore to adjust the pH value of the pulp to 10.5-11.0, and grind to -0.074mm to account for 55%; add a combined collector of 64 g / ton (OL, butyl ammonium black medicine, PAX combination, the proportion of the three is 3: 3:1), add inhibitor TCM 80 g / ton of raw ore and foaming agent MIBC 24 g / ton of raw ore, and obtain roughing concentrate and roughing tailings by flotation. The tailings 1 are obtained after the roughing tailings are swept twice.

[0031] After the rough beneficiation concentrate goes through a blank beneficiation, a section of beneficiation concentrate is obtained. The first-stage sorting concentrate is subjected to the second-stage grinding, and the ground product is sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com