A middle and low grade mixed type collophanite flotation separation agent system and its application

A mixed type collophosite technology, applied in flotation, solid separation, etc., can solve the problems affecting the recovery rate of concentrate, affecting the application of mineral processing backwater, shortening the service life of equipment, etc., to increase the selective inhibition, The effect of prolonging the service life and improving the sortability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

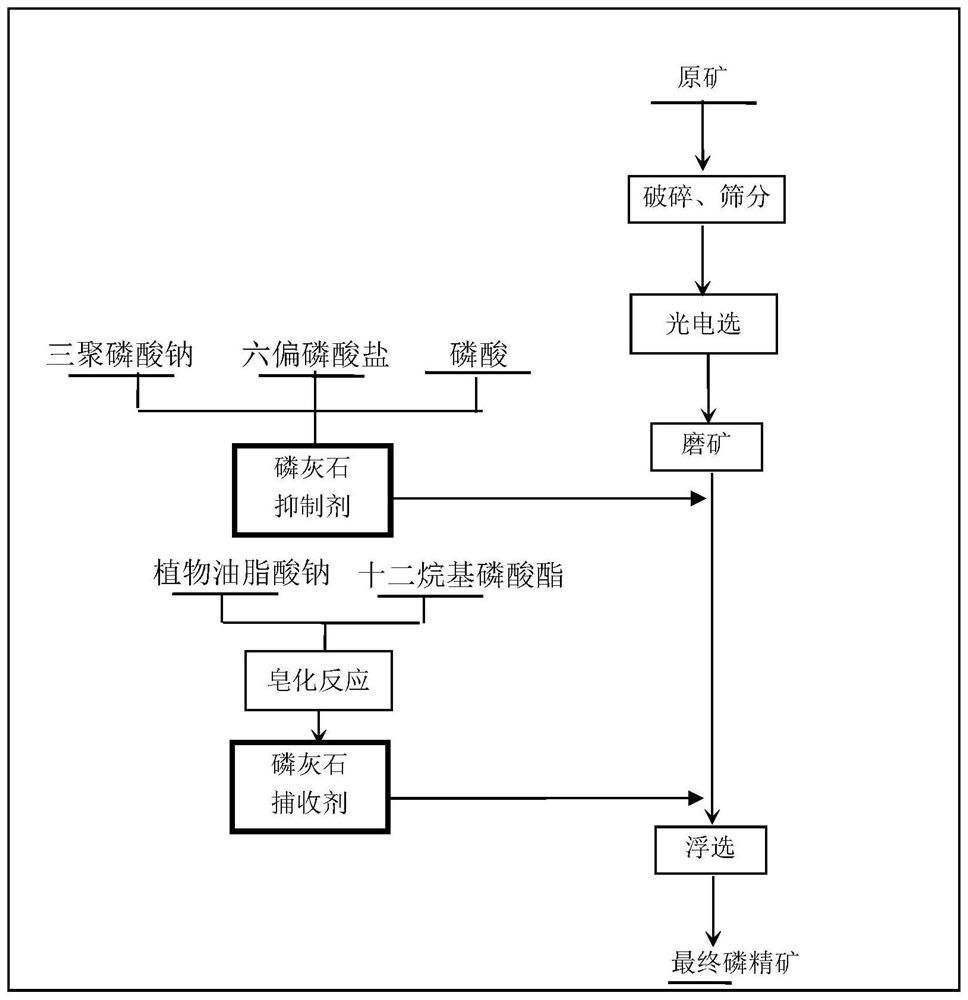

Method used

Image

Examples

Embodiment 1

[0042] 1. A middle and low-grade mixed type collophanite flotation separation agent system, including inhibitors and collectors;

[0043]In parts by weight, the inhibitor includes 4 parts of sodium tripolyphosphate, 2 parts of hexametaphosphate and 2 parts of phosphoric acid, and the collector includes 4 parts of sodium vegetable oil and 1 part of dodecyl phosphate.

[0044] The preparation method of the collector is that the NaOH solution with a concentration of 20% by mass is added into the mixed solution of vegetable oil and dodecyl phosphate, and the heating reaction is carried out under the condition of 60° C. for 5 hours.

[0045] Among them, the vegetable oil is cottonseed oil, rice bran oil, castor oil, corn oil and soybean oil; the weight ratio of NaOH solution to the mixed solution is 0.2:1.

[0046] 2. The application method of the medicament, comprising the following steps:

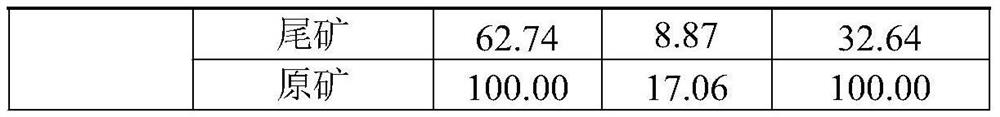

[0047] S1-1. Paramixed collophosite (taken from a dressing plant in Mabian area, P 2 o ...

Embodiment 2

[0059] 1. A middle and low-grade mixed type collophanite flotation separation agent system, including inhibitors and collectors;

[0060] In parts by weight, the inhibitor includes 5.5 parts of sodium tripolyphosphate, 2.5 parts of hexametaphosphate and 2.5 parts of phosphoric acid, and the collector includes 4.5 parts of sodium vegetable oil and 1 part of dodecyl phosphate.

[0061] The preparation method of the collector is that the NaOH solution with a concentration of 20% by mass is added to the mixed solution of vegetable oil and dodecyl phosphate, and the heating reaction is carried out at 70° C. for 4 hours to obtain the final product.

[0062] Among them, the vegetable oil is cottonseed oil, rice bran oil, castor oil, corn oil and soybean oil; the weight ratio of NaOH solution to the mixed solution is 0.2:1.

[0063] 2. The application method of the medicament, comprising the following steps:

[0064] S1-1. Paramixed collophosite (taken from Leibo factory, P 2 o 5 G...

Embodiment 3

[0076] 1. A middle and low-grade mixed type collophanite flotation separation agent system, including inhibitors and collectors;

[0077] In parts by weight, the inhibitor includes 6 parts of sodium tripolyphosphate, 3 parts of hexametaphosphate and 3 parts of phosphoric acid, and the collector includes 5 parts of sodium vegetable oil and 1 part of dodecyl phosphate.

[0078] The preparation method of the collector is that the NaOH solution with a concentration of 20% by mass is added to the mixed solution of vegetable oil and dodecyl phosphate, and the heating reaction is carried out under the condition of 80° C. for 3 hours.

[0079] Among them, the vegetable oil is cottonseed oil, rice bran oil, castor oil, corn oil and soybean oil; the weight ratio of NaOH solution to the mixed solution is 0.2:1.

[0080] 2. The application method of the medicament, comprising the following steps:

[0081] S1-1. Paramixed collophosite (taken from a concentrator in Jinyang, P 2 o 5 Grade...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com