Core sand for automobile engine casting and preparation method of core sand

A technology of automobile engine and core sand, which is applied to casting molding equipment, molds, cores, etc. It can solve the problems of poor finish, poor air permeability of sand molds, and rough surface of aluminum sand parts, so as to achieve good air permeability and reduce Sensitivity, short drying time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A core sand for automobile engine casting, prepared from the following parts by weight (kg) of raw materials: forsterite sand 170, graphite sand 40, high magnesium phosphorus tailings 35, skarn 40, waste foamed concrete 25, wood Section clay 40, coal powder 15, coconut bran 16, blast furnace gas ash 14, high alumina fine powder 8, calcium zirconate 10, hollow silica nanosphere 15, sodium silicate 2, aluminum silicate 3, ammonium alginate 3 , Hydroxyethyl cellulose 4, β-cyclodextrin 4, appropriate amount of water.

[0016] A preparation method of core sand for automobile engine casting includes the following steps:

[0017] (1) Mix the high-magnesium phosphorus tailings slag, skarn, and waste foamed concrete evenly, crush them into a particle size of 130-150 mesh, and then add graphite sand, blast furnace gas ash, high alumina fine powder, calcium zirconate, and appropriate amount of water Stir and disperse, smelt the mud, send it to a calciner at 1300-1350°C for calcination...

Embodiment 2

[0021] A core sand for automobile engine casting, prepared from the following parts by weight (kg) of raw materials: forsterite sand 175, graphite sand 47.5, high magnesium phosphorus tailings 37.5, skarn 50, waste foam concrete 27.5, wood Clay 45, coal powder 16.5, coconut bran 18, blast furnace gas ash 15, high alumina fine powder 10, calcium zirconate 12.5, hollow silica nanosphere 16, sodium silicate 2.5, aluminum silicate 4, ammonium alginate 3.5 , Hydroxyethyl cellulose 5, β-cyclodextrin 5.5, appropriate amount of water.

[0022] The preparation method is the same as in Example 1.

Embodiment 3

[0024] A core sand for automobile engine casting, prepared from the following parts by weight (kg) of raw materials: forsterite sand 180, graphite sand 55, high magnesium phosphorus tailings 40, skarn 60, waste foam concrete 30, wood Section clay 50, coal powder 18, coconut bran 20, blast furnace gas ash 16, high alumina fine powder 12, calcium zirconate 15, hollow silica nanosphere 17, sodium silicate 3, aluminum silicate 5, ammonium alginate 4 , Hydroxyethyl cellulose 6, β-cyclodextrin 7, appropriate amount of water.

[0025] The preparation method is the same as in Example 1.

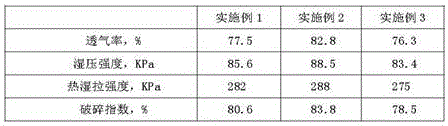

[0026] The performance test results of the foundry core sand prepared in the above Examples 1-3 are shown in the following table:

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com