Centrifuge and method for centrifuging a reaction vessel unit

A reaction vessel and centrifuge technology, applied in the field of centrifuges, to reduce the risk of cross-contamination and achieve the effect of small platform space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

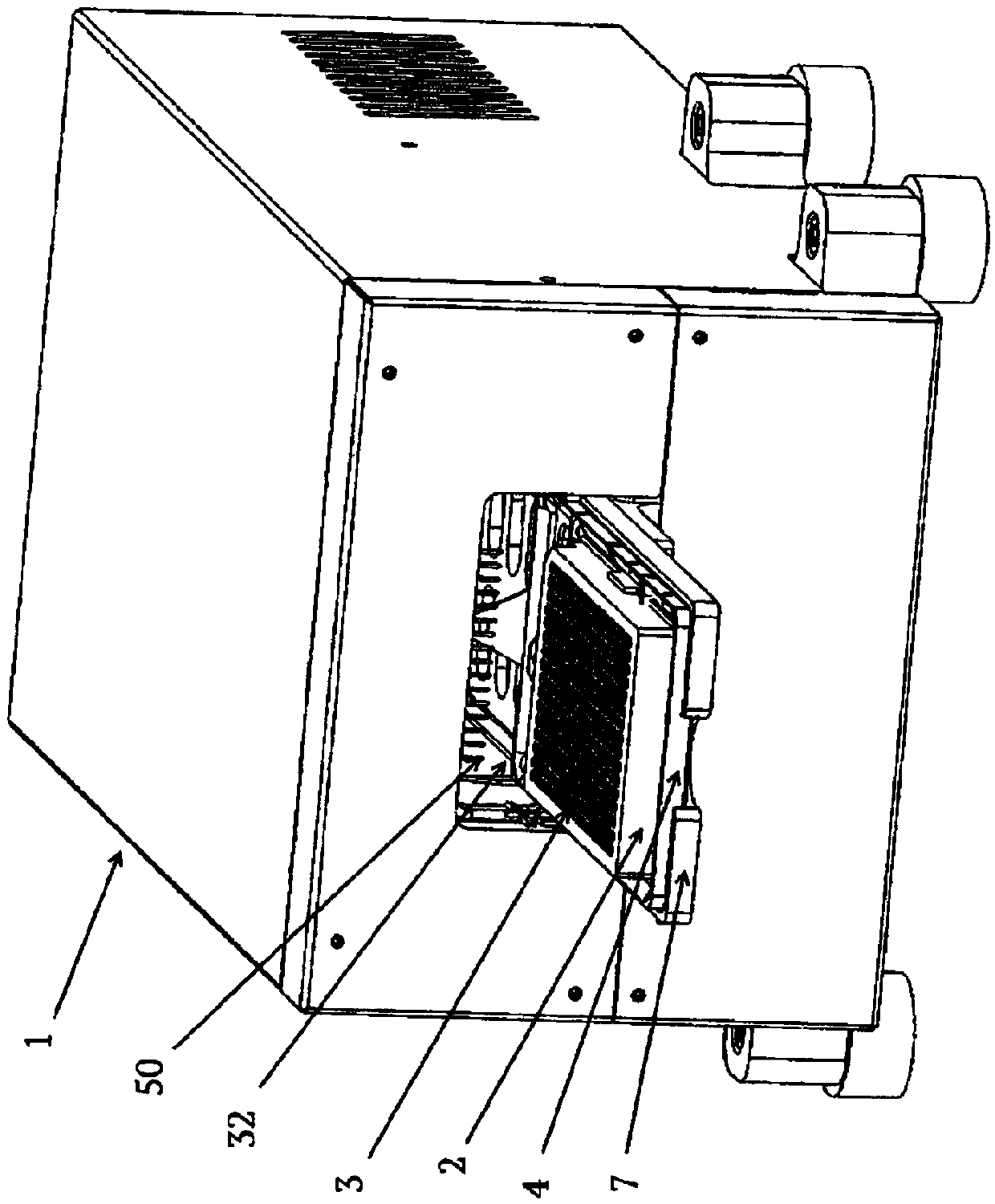

[0092] The first instance of the centrifuge ( Figure 1-Figure 7 ) designed for cleaning and cleaning of the reaction vessel unit. The reaction vessel unit is a microtiter plate 2 . The microtiter plate 2 includes a plurality of reaction vessels 3 arranged in a two-dimensional array. Such microtiter plates typically contain 96, 384 or 1536 reaction volumes3.

[0093] Centrifuge 1 comprises front desk 4, centrifugal part 5 and driving part 6 ( figure 1 ).

[0094] The front desk 4 has a rectangular form in plan view slightly larger than a standard microtiter plate. The outer edge 7 is provided on all side edges of the front desk 4 except for one outer edge adjacent to the eccentric portion 5 .

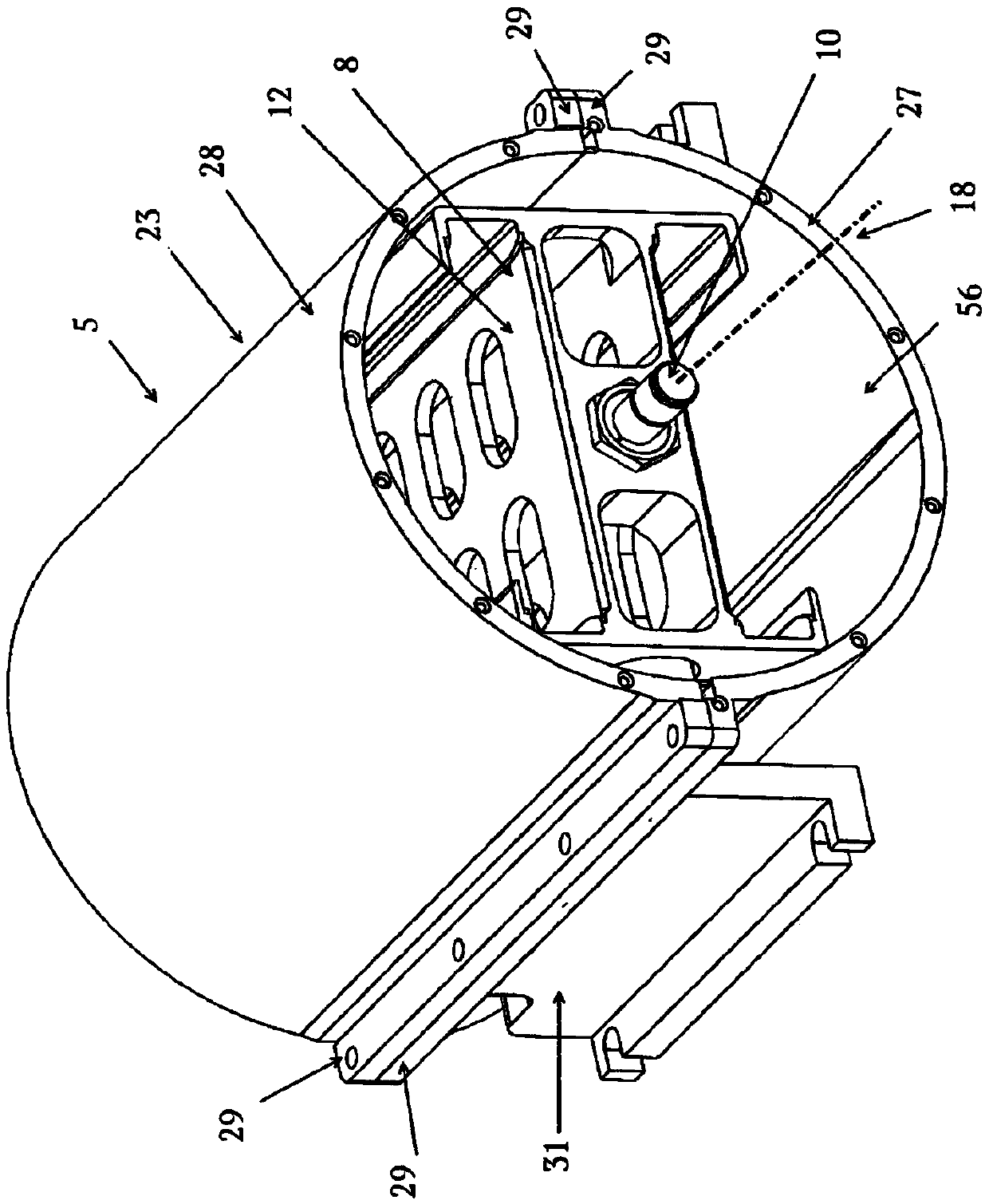

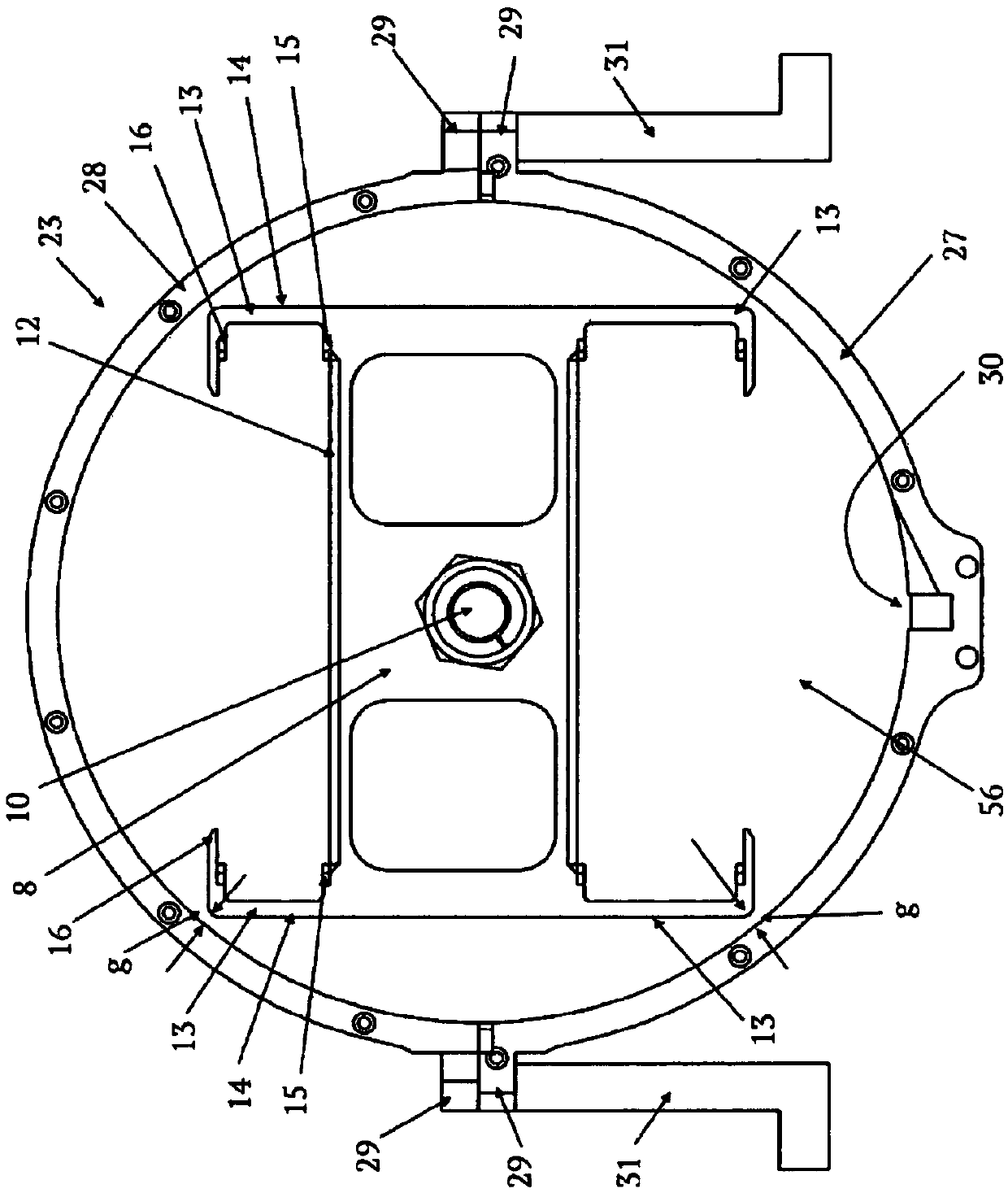

[0095] The centrifugal part 5 includes a rotor 8 and a housing 9 . The rotor 8 is installed on the horizontal shaft 10 ( figure 2 , image 3 ). The rotor 8 comprises two receiving parts, each for receiving a microtiter plate 2 . The receiving part is implemented as a plate tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com