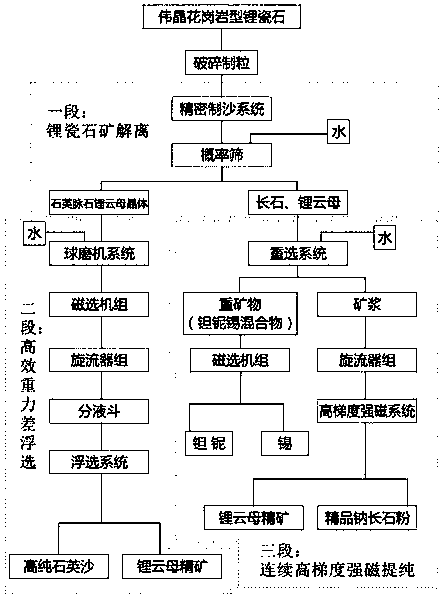

Technology of extracting lepidolite from lithium porcelain stone ore

A lithium china stone and lithium extraction technology, applied in solid separation, high gradient magnetic separation, grain processing, etc., can solve the problems of difficult processing, low production capacity, inflexible process route, etc., achieving small investment, large production capacity, suitable for promotion applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A process for extracting lepidolite from lithium china stone ore, the process specifically includes the following steps:

[0027] (1) Lithium china stone ore dissociation: the pegmatite granite type lithium china stone is crushed and granulated to obtain 3cm ore particles, and the ore particles are sent to the precision sand making system, and the ore particles are made in the original control volume of the sand making machine. Free fall movement, the rebar in the sand making machine has four stages of rapid impact on the ore particles: the first and second stages play the role of impacting finely crushed ore particles, with the free fall of the ore particles and the gradual change of the volume space Small, under the action of super-fast friction and impact in the third and fourth stages, the ore crystals disintegrate naturally to obtain 900um fine sand; the fine sand is sieved by a probability sieve after adding water to obtain a mixture of quartz gangue and lepidolite...

Embodiment 2

[0032] A process for extracting lepidolite from lithium china stone ore, the process specifically includes the following steps:

[0033] (1) Dissociation of lithium china stone ore: crush and granulate the pegmatite granite type lithium china stone to obtain 1.6cm ore particles, and send the ore particles to the precision sand making system, and the ore particles are in the original control volume of the sand making machine In the free fall movement, the rebar in the sand making machine will quickly impact the ore particles in four stages: the first stage and the second stage play the role of impacting the finely crushed ore particles, with the free fall of the ore particles and the gradual increase of the volume space Under the action of ultra-fast friction and impact in the third and fourth stages, the ore crystals disintegrate naturally to obtain 800um fine sand; the fine sand is sieved by a probability sieve after adding water to obtain a mixture of quartz gangue and lepido...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com