Separation method for cathode and anode plates in recovery process of lithium ion batteries

A technology for lithium-ion batteries and positive and negative electrodes, applied in the field of lithium-ion battery recycling, can solve the problems of waste of resources, waste, and low efficiency of the separation method of positive and negative electrodes, and achieve improved recovery rate, recovery purity, and low recycling costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The method for separating the positive and negative plates in the lithium ion battery recycling process of the present embodiment may further comprise the steps:

[0022] 1) Discharge the lithium iron phosphate lithium-ion battery, discharge the electrolyte, then disassemble, remove the shell, cover plate and the pole on the cover plate, and then break the battery cell to obtain fragments with a size of about 5mm;

[0023] 2) Sorting: After the fragments obtained in step 1) are removed by negative pressure air separation to obtain the mixed fragments of positive electrode fragments and negative electrode fragments;

[0024] 3) The mixed fragments are transported to the magnetic roller of the magnetic separator through the conveyor belt, and the magnetic field with a magnetic induction intensity of 9500Gs is used to magnetically separate the mixed pole pieces to separate the magnetic positive pole fragments from the non-magnetic negative pole fragments.

[0025] Using th...

Embodiment 2

[0027] The method for separating the positive and negative plates in the lithium ion battery recycling process of the present embodiment may further comprise the steps:

[0028] 1) Discharge the lithium cobalt oxide lithium-ion battery, discharge the electrolyte, then disassemble, remove the shell, cover plate and the pole on the cover plate, and then crush the battery cell to obtain fragments with a size of about 40mm;

[0029] 2) Sorting: After the fragments obtained in step 1) are removed by negative pressure air separation to obtain the mixed fragments of positive electrode fragments and negative electrode fragments;

[0030] 3) The mixed fragments are transported to the magnetic roller of the magnetic separator through the conveyor belt, and the magnetic field with a magnetic induction intensity of 10000Gs is used to magnetically separate the mixed fragments, and the magnetic positive pole fragments are selected to obtain the remaining mixed fragments;

[0031] 4) The rem...

Embodiment 3

[0036] The method for separating the positive and negative plates in the lithium ion battery recycling process of the present embodiment may further comprise the steps:

[0037] 1) Discharge the aluminum-shell nickel-cobalt lithium-manganese oxide lithium-ion battery, discharge the electrolyte, and then break it as a whole to obtain fragments with a size of about 70mm;

[0038] 2) Sorting: the fragments obtained in step 1) are firstly removed by a negative pressure winnowing machine to remove the diaphragm, and then the lithium-ion battery casing is removed by an eddy current separator to obtain mixed fragments of positive electrode fragments and negative electrode fragments;

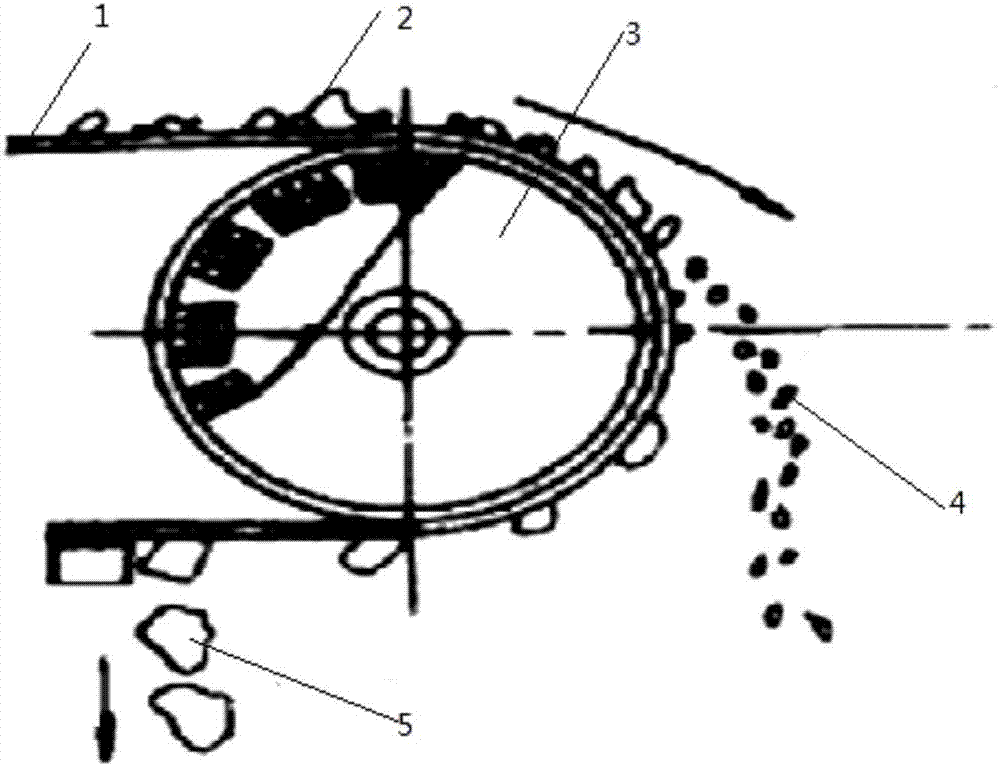

[0039] The steps of eddy current separator to remove the lithium-ion battery case are as follows: the debris mixture after removing the diaphragm is passed through the eddy current separator with a field strength of 5400Gs and a magnetic roller width of 500mm at a feeding speed of 3kg / min; Rotate clockw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic induction | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com