An apparatus and a method for sorting a particulate material

A technology for granular materials and equipment, which is applied in the field of equipment and methods for classifying granular materials, can solve the problems of frequent maintenance, reduced reliability, and classification of classified materials into multiple grades, so as to increase mechanical reliability , Reduce the effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

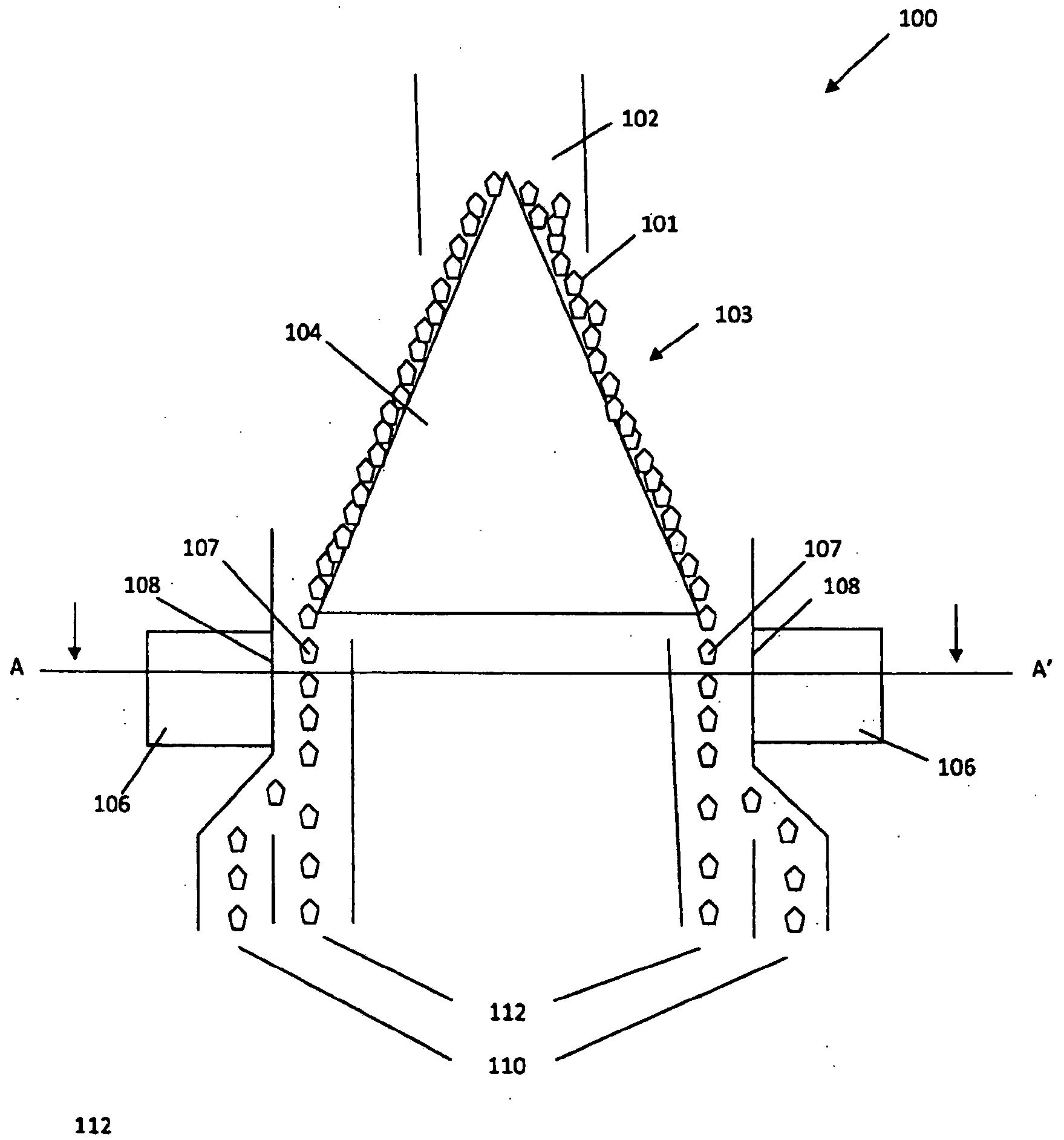

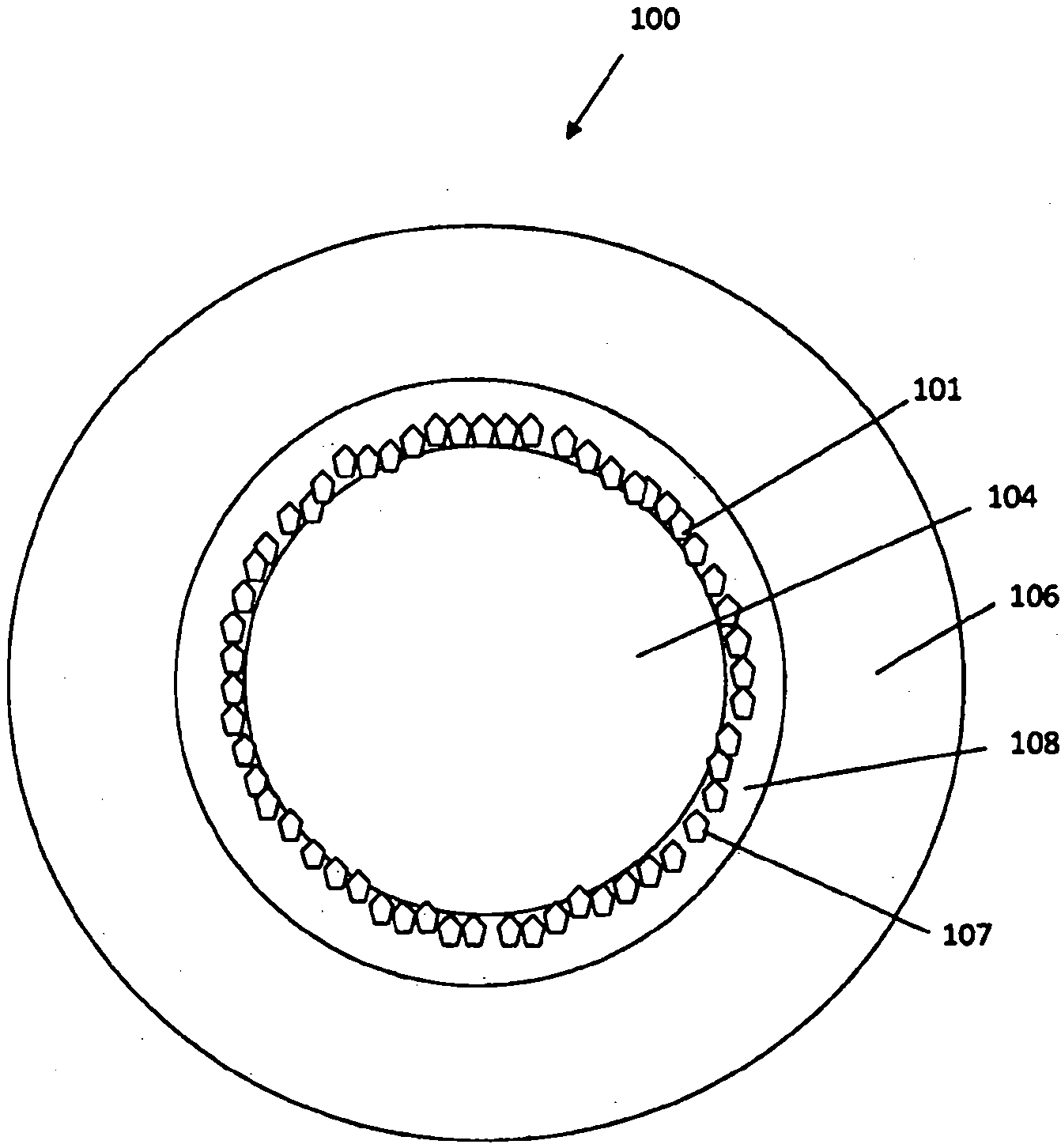

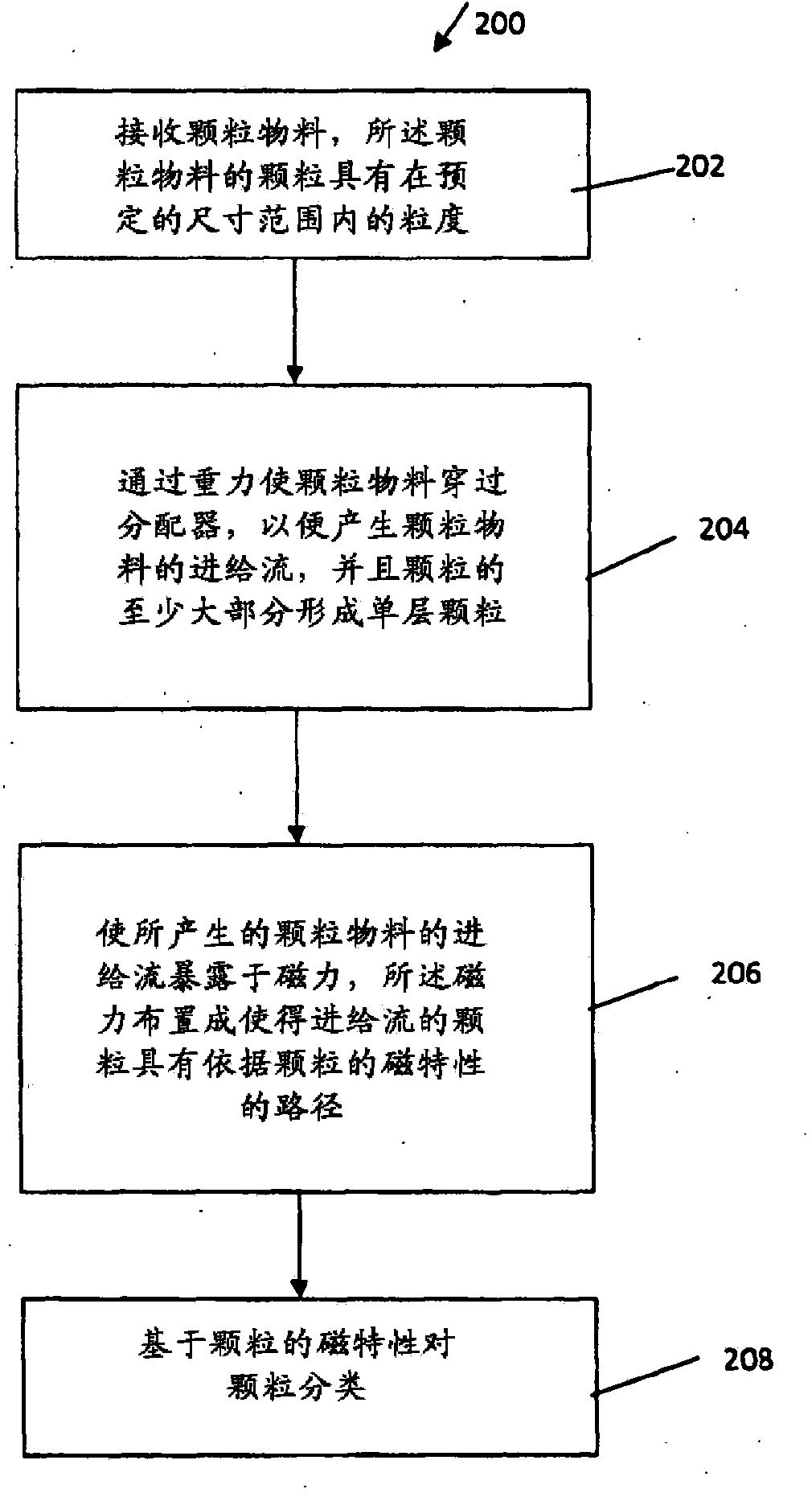

[0052] now refer to Figure 1 to Figure 3 , illustrates an apparatus and method for classifying granular materials according to a specific embodiment of the present invention. figure 1 with figure 2 The apparatus 100 shown in is arranged for sorting particulate material 101 such as iron ore. The apparatus 100 has a receiving portion or feed box 102 for receiving the granular material 101, and the apparatus 100 comprises a distributor 103 arranged to distribute the received granular material 101 such that a monolayer feed stream 107 of the granular material flows from The dispenser 103 falls. The apparatus 100 is arranged for handling particulate material by gravity.

[0053] In this embodiment, the dispenser 103 includes a conical dispensing surface 104, and the particles of the particulate material 101 slide, roll, fall or otherwise move along the conical dispensing surface 104, generally under the influence of gravity. The slope, size and feed of the conical distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com