Ultrasonic dispersing-magnetic separating process for copper-molybdenum bulk concentrate

A copper-molybdenum mixed concentrate, magnetic separation technology, applied in the direction of magnetic separation, high-gradient magnetic separation, high-gradient magnetic separator, etc., can solve the problem of separation, secondary pollution, lower molybdenum grade and recovery rate of molybdenum concentrate and other issues, to achieve the effect of eliminating environmental hazards, reducing mechanical inclusions, and excellent environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Copper grade of copper molybdenum sulfide mixed concentrate is 21.52%, molybdenum grade is 2.93%, the content of chalcopyrite and bornite in copper minerals in copper minerals (that is, the total content of both chalcopyrite and bornite) The content of molybdenite in molybdenum minerals is 94.7%, the content of molybdenite in molybdenum minerals is 98.3%, the ore with fineness less than 74μm in copper sulfide molybdenum mixed concentrate accounts for 86%, and the monomer dissociation degree of copper minerals and molybdenum minerals is 96.5%. .

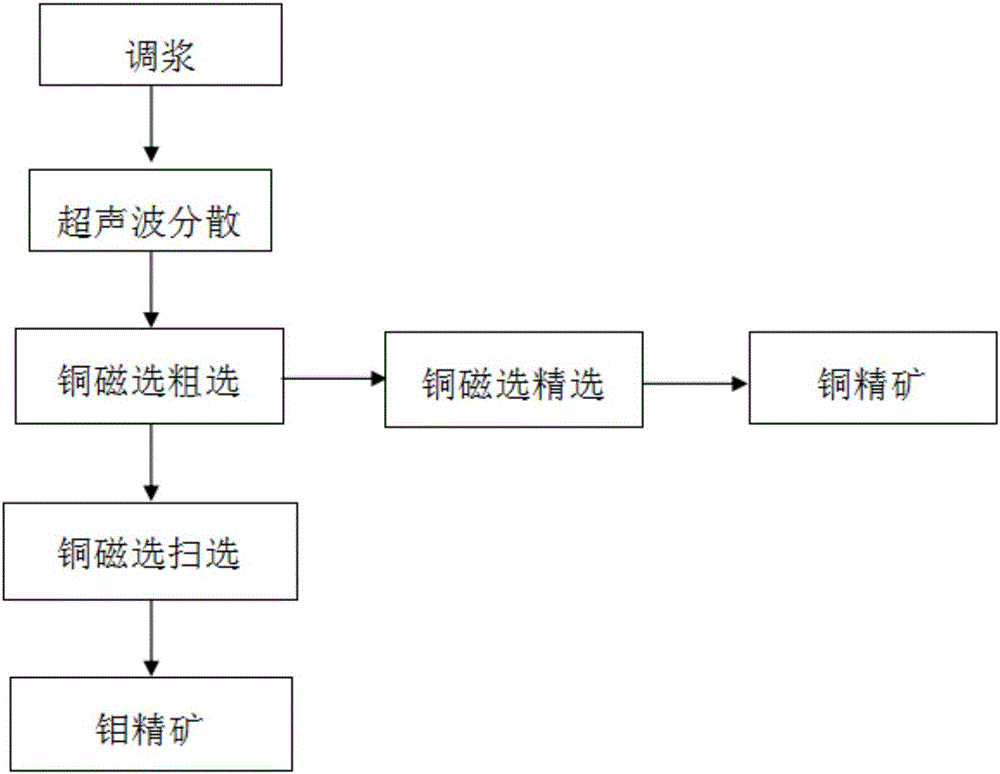

[0026] The magnetic separation process is as figure 2 As shown, the copper-molybdenum mixed concentrate slurry is adjusted to a pulp concentration of 15% to obtain a copper-molybdenum mixed concentrate slurry, and then an ultrasonic disperser is used to ultrasonically disperse the copper-molybdenum mixed concentrate slurry to make the copper-molybdenum mixed concentrate slurry The copper-molybdenum ore particles in the medium...

Embodiment 2

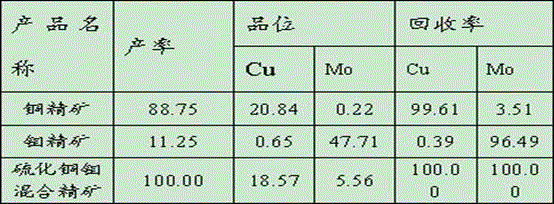

[0032] The copper grade of copper-molybdenum sulfide mixed concentrate is 18.55%, the grade of molybdenum is 5.60%, the content of chalcopyrite and bornite in copper minerals (that is, the total content of chalcopyrite and bornite) is 93%, and the The content of molybdenite in the mineral is 96%, the copper-molybdenum mixed concentrate ore with a fineness less than 74μm accounts for 88%, and the monomer dissociation degree of copper mineral and molybdenum mineral is 96%.

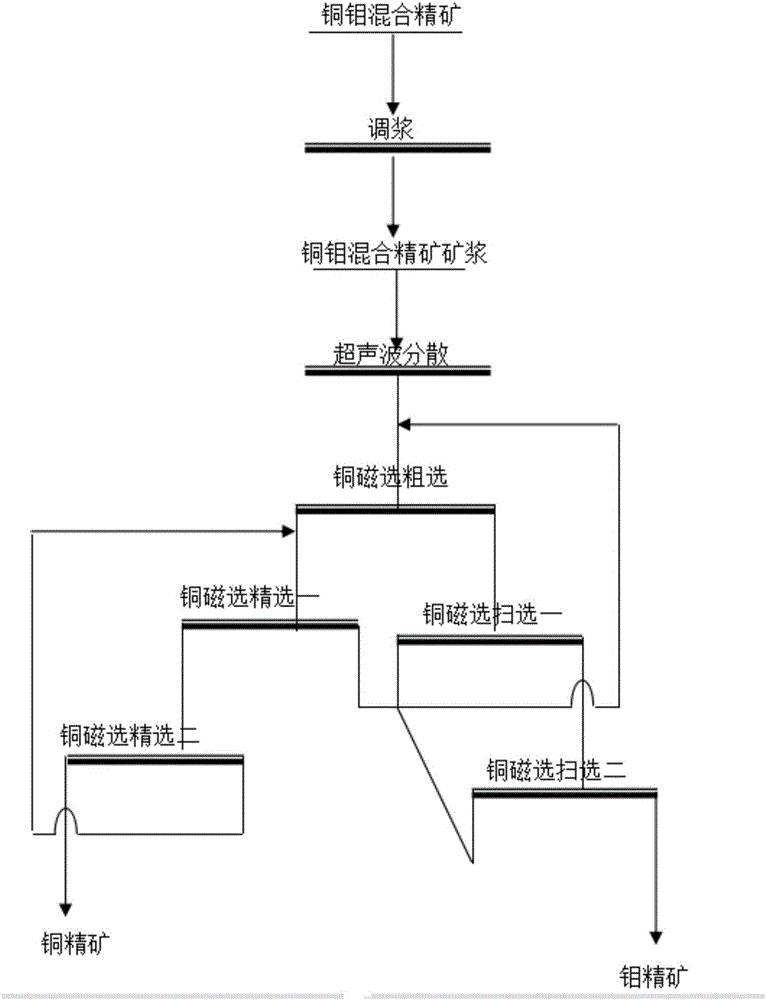

[0033] The mixed copper-molybdenum sulfide concentrate is slurried until the concentration of the pulp is 15%, and the copper-molybdenum mixed concentrate slurry is obtained, and then the copper-molybdenum mixed concentrate slurry is ultrasonically dispersed by an ultrasonic disperser to make the copper-molybdenum mixed concentrate slurry The copper-molybdenum ore particles are dispersed to eliminate the agglomeration between the copper-molybdenum ore particles. The magnetic field strength of the high-gradien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com