Filter device and method for removing magnetizable particles from a fluid

A filtering device and technology of magnetic particles, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of labor-intensive, complicated, and difficult to clean magnets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

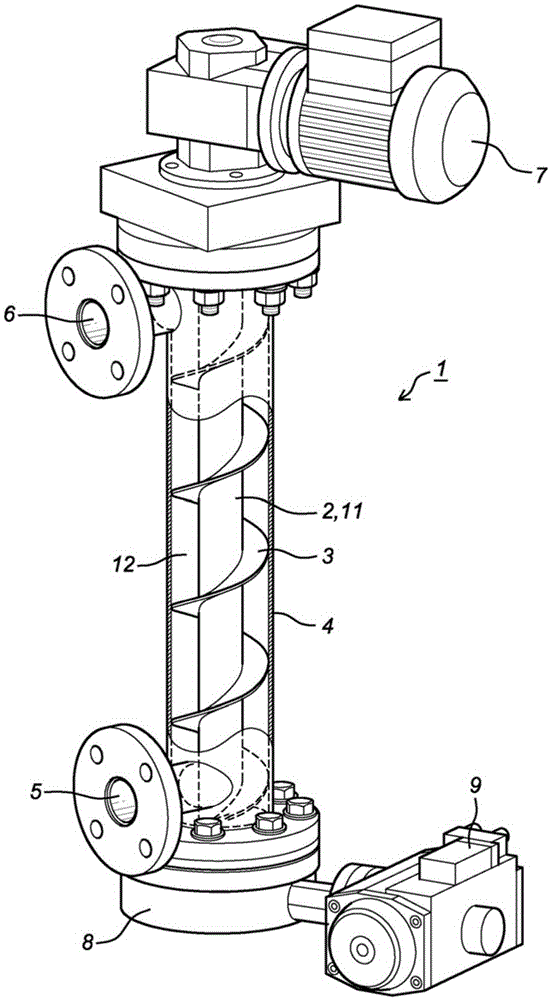

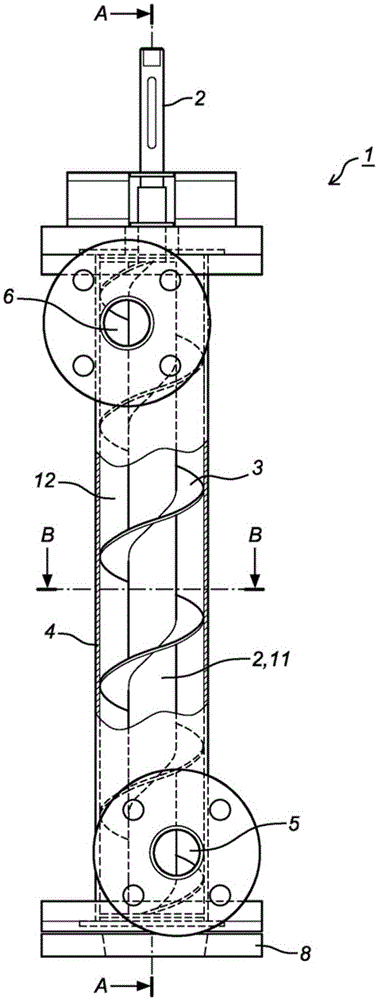

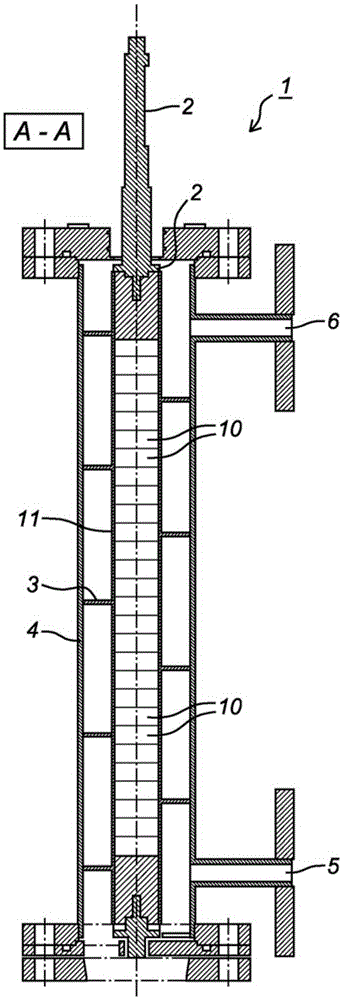

[0017] figure 1 is a perspective view of a filter device 1 according to the invention. This filter device 1 is also referred to as a magnetic separator or magnetic filter. The filter device 1 comprises a rotatable central shaft 2 around which a fixed worm 3 (Archimedes screw) meshing with the central shaft 2 is arranged, wherein the worm 3 is partially (half- Continuous) welding and connected to the shell 4. The casing 4 completely surrounds the worm, although to show the worm 3 and the central shaft 2, the casing 4 is in figure 1 is partially omitted. The housing is provided with a supply port 5 for treating water laden with metal particles and a discharge port 6 at a higher level for discharging at least partially purified water. The upper end surface 4 a of the casing 4 is coupled to a motor 7 for axially rotating the center shaft 2 . As shown in the top view, the direction of rotation of the central shaft 2 is clockwise. The lower end surface 4b of the casing 4 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com