Novel high-efficiency inner circulation oil-cooling iron remover

A technology of internal circulation and iron remover, which is applied in the direction of high gradient magnetic separator, high gradient magnetic separation, chemical instruments and methods, etc., can solve problems such as the failure of iron remover to work normally, solder joint cracking and oil leakage, complex oil circuit layout, etc. , to achieve the effects of reducing solder joint leakage, improving performance, and oil circulation is even and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

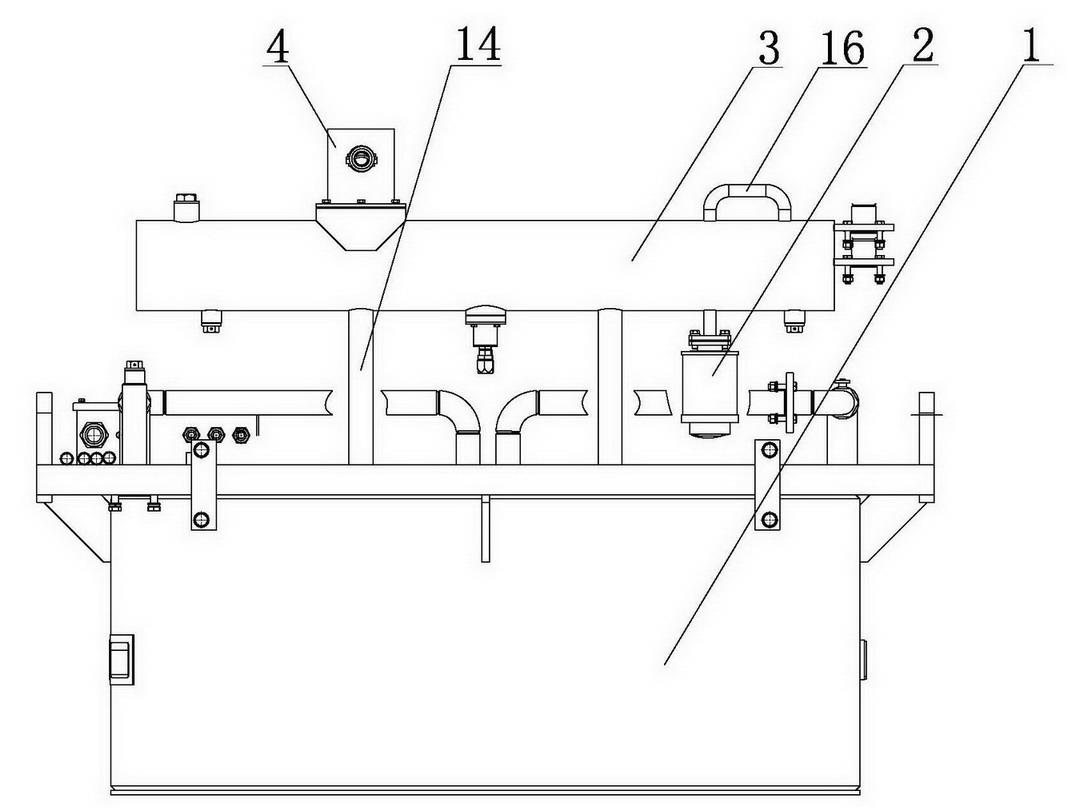

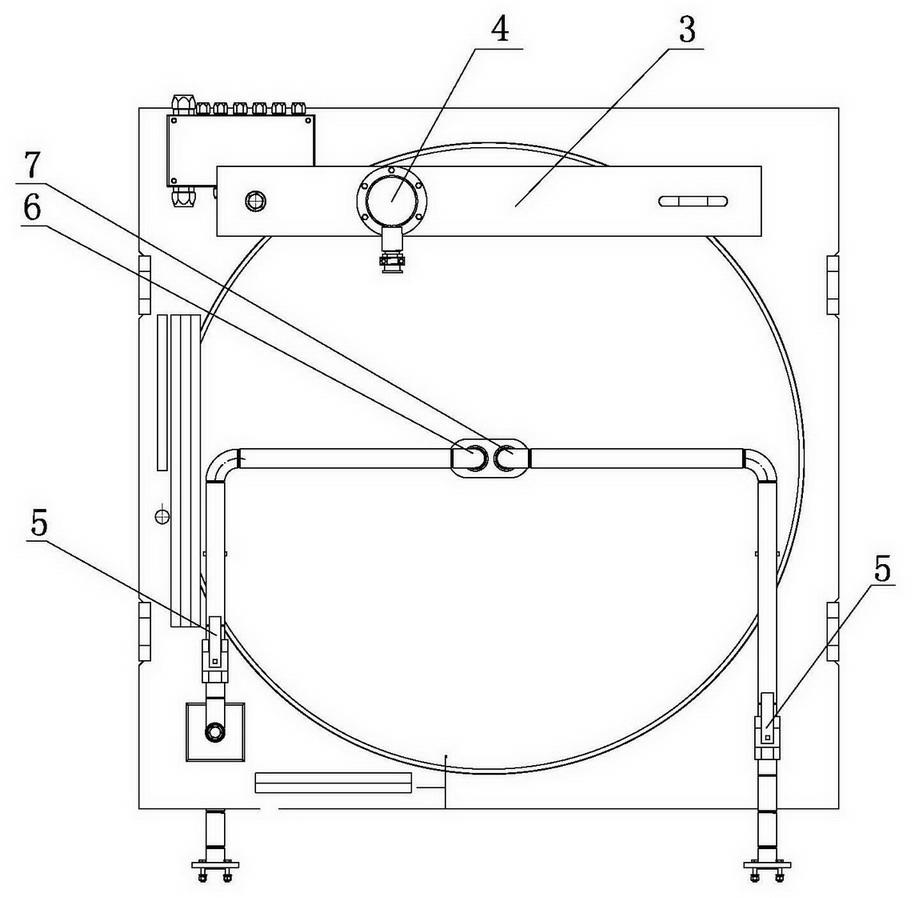

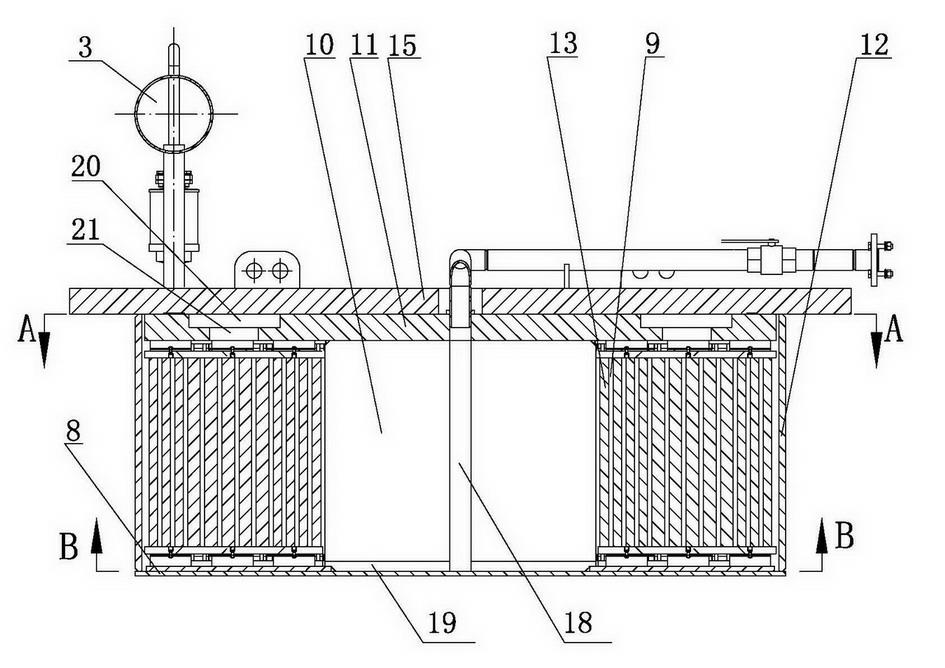

[0011] As shown in the figure, the present invention includes a sealed casing 1 composed of a yoke plate, a supporting plate 8 and a magnetically conductive plate 12 and a magnetic system inside the casing 1 . The magnetic system 1 is composed of an iron core 10 and a coil 13 wound outside the iron core 10 . The coil 13 is a multi-layer structure, and oil passages 9 are left between the layers. The yoke plate is composed of a large yoke plate 15 at the top and a small yoke plate 11 at the bottom. The large yoke plate 15 is provided with an oil inlet pipe 6 , an oil outlet pipe 7 and an oil conservator 3 . There is a valve 5 at the inlet of the oil inlet pipe 6 and the outlet of the oil outlet pipe 7. When the valve is closed during equipment maintenance, the external radiator and circulation pump can be repaired, which shortens the maintenance time and ensures the production of the iron remover. continuity. The junction box 4 of the coil 13 is arranged on the top of the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com