Magnetic hydrocyclone, magneto-gravitational combined separation system and magneto-gravitational combined separation method applied to weakly-magnetic mineral selection

A technology of hydrocyclone and magnetic gravity combination, which is applied in the direction of magnetic separation, chemical instruments and methods, cyclone devices, etc., can solve the problems of low recovery rate of fine-grained weak magnetic minerals, and achieve easy adjustment and control, and environmentally friendly technology , The effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

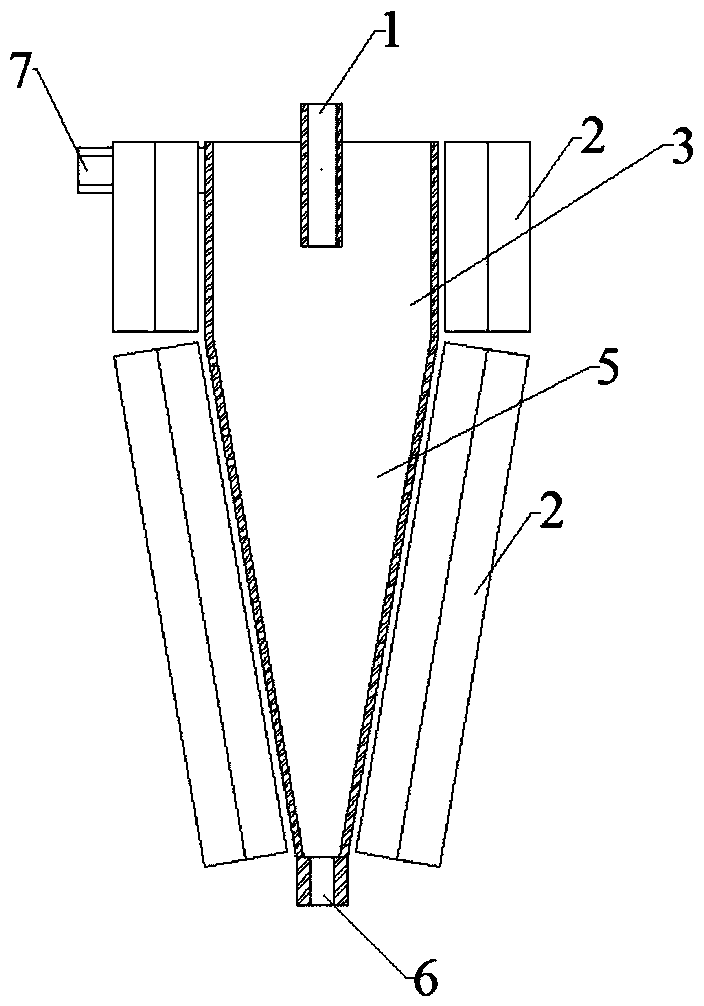

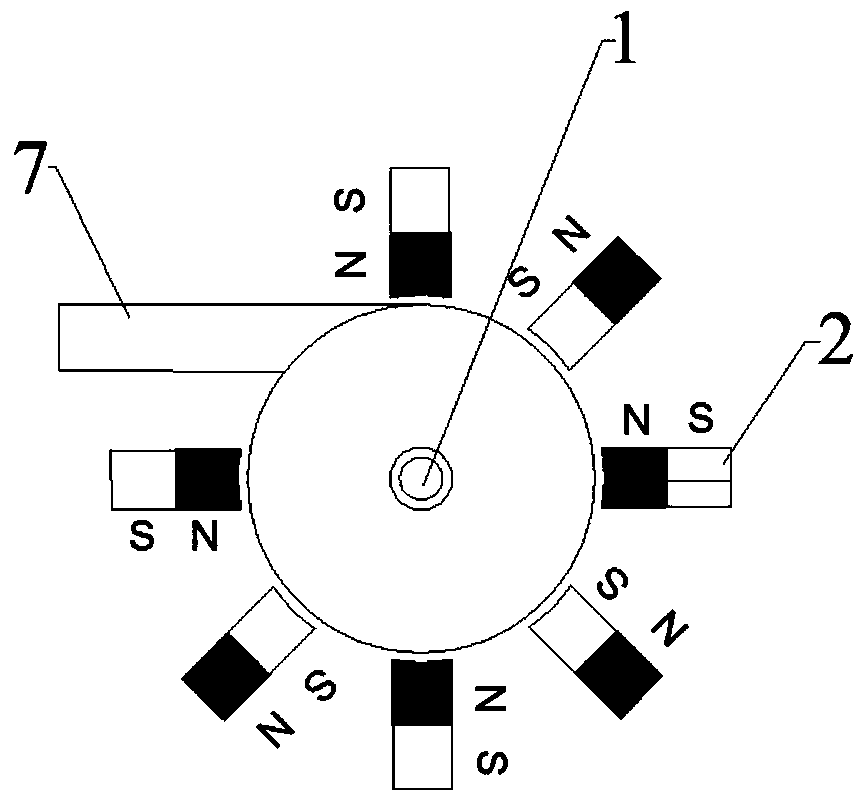

[0033] Such as figure 1 and figure 2 As shown, the magnetic hydrocyclone used for weak magnetic mineral concentration in this embodiment includes a hydrocyclone, and the outer wall of the hydrocyclone is uniformly provided with a plurality of permanent magnets 2 for forming a magnetic field gradient, and the magnetic field gradient The direction is from the inside of the hydrocyclone to the outside.

[0034] In this embodiment, the polarities of the permanent magnets 2 are arranged alternately on the side close to the outer wall of the hydrocyclone, and the permanent magnets 2 are all perpendicular to the outer wall of the hydrocyclone. The highest magnetic field generated by the permanent magnet 2 is 0.4T.

[0035] In this embodiment, the hydrocyclone includes a cylindrical section 3 and a conical section 5 that are connected to each other. There is an ore feeding port 7, and the bottom of the conical section 5 is provided with a settling nozzle 6. Both the cylindrical s...

Embodiment 2

[0043] The magnetic hydrocyclone in this embodiment is the same as that in Embodiment 1.

[0044] The combined magnetic-gravity separation system of this embodiment includes the above-mentioned magnetic hydrocyclone and a vertical ring high-gradient magnetic separator.

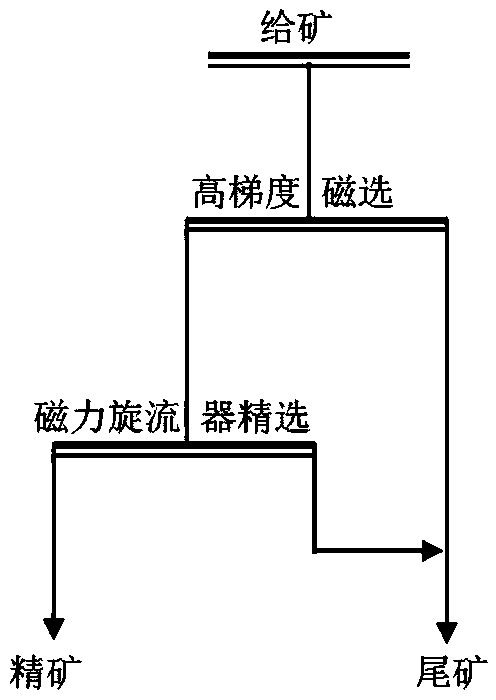

[0045] Utilize the magnetic hydrocyclone in the present embodiment to carry out the method for combined magnetic gravity separation of hematite, comprising the following steps:

[0046] S1: Grinding weakly magnetic hematite with a grade of 25% to -200 mesh accounts for 80%, and pulping to a mass concentration of 35%, as ore feed;

[0047] S2: use the vertical ring high gradient magnetic separator to rough the above-mentioned feed ore under the condition of 5000-10000GS to obtain rough concentrate, and adjust the coarse concentrate to 45%;

[0048] S3: Use a pump to send it into the magnetic hydrocyclone through the ore feeding port 7 for separation to obtain sand settling and overflow. The ore feeding pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com