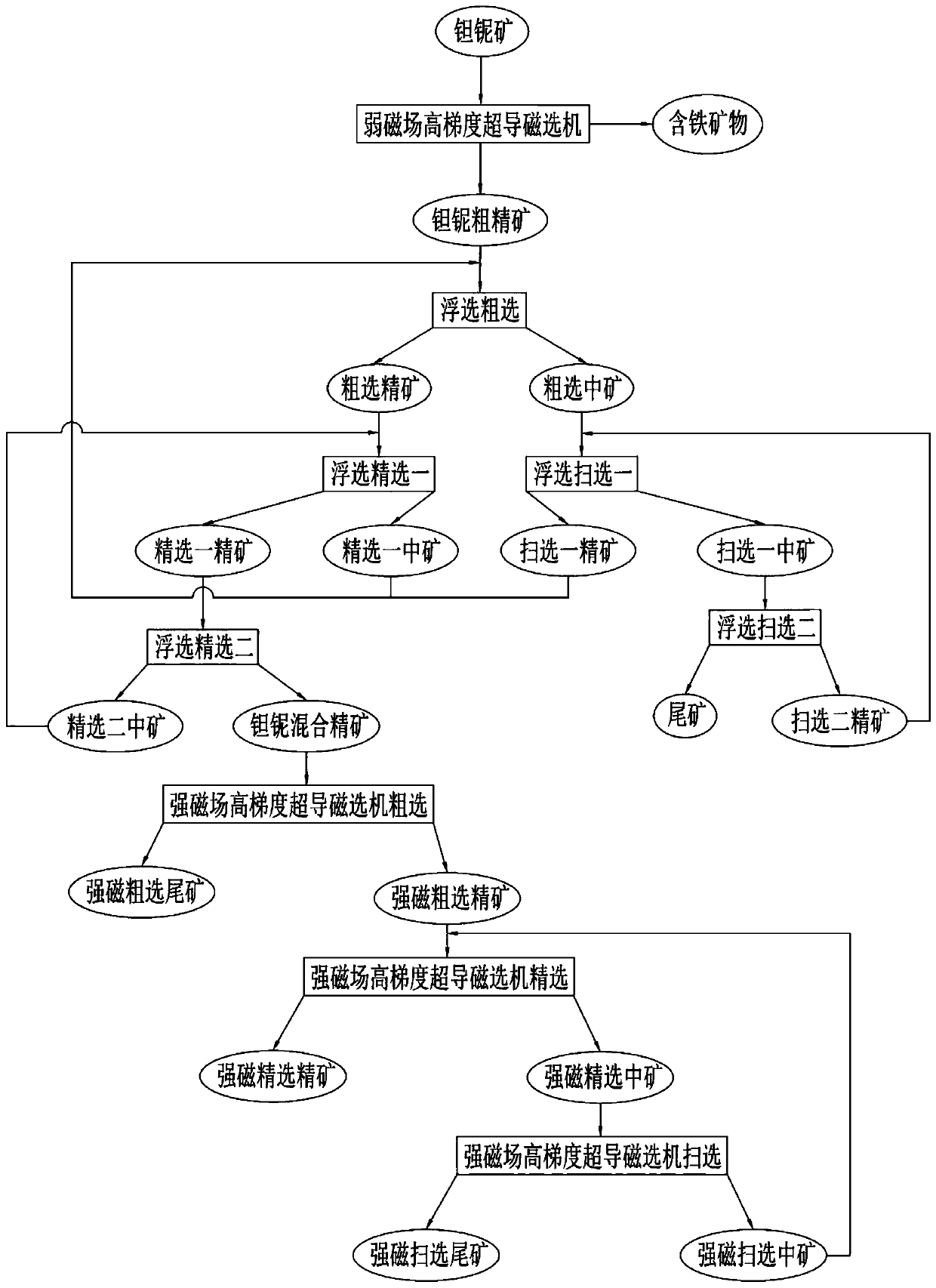

Sorting process of micro-fine particle low-grade tantalum-niobium ore

A low-grade technology for tantalum-niobium ore, which is applied in the field of short-flow sorting process, can solve the problems of reducing the utilization rate of tantalum-niobium resources, shortening the process flow, and increasing the cost of sorting, so as to achieve efficient sorting and development and utilization, shorten Process flow and consumption saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions in the specific embodiments of the present invention are clearly and completely described below to further illustrate the present invention. Obviously, the described specific implementation The form is only a part of embodiment of this invention, and it is not all form.

[0026] This specific embodiment adopts the method of magnetic-flotation combined separation to separate fine-grained, low-grade tantalum-niobium ore. This embodiment is aimed at a large-scale tantalum-niobium-tungsten deposit in Jiangxi Province. Ta 2 o 5 The content is 0.0108%, Nb 2 o 5 It is 0.0040%; the main useful minerals are tantalum-niobite, fine crystal, tantalum calcite, and the main gangue minerals are mica and feldspar. About 80% of the tantalum and niobium minerals embedded in the raw ore have a particle size of 50-0μm, of which -38um T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com