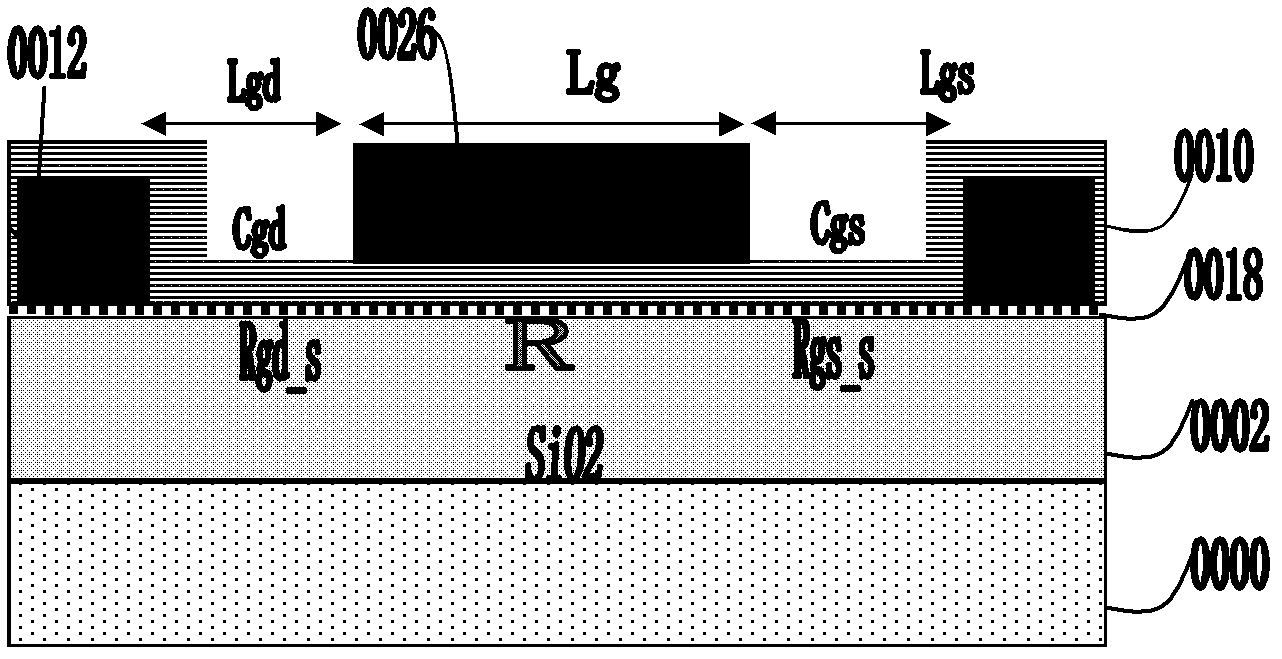

Source-drain buried graphene transistor device on diamond-like carbon substrate and manufacture method

A diamond and graphene technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of reducing graphene carrier mobility, reducing parasitic capacitance and channel resistance, and restricting device high-frequency performance. and size and other issues, to achieve the effect of small horizontal spacing, small channel resistance, and small parasitic capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and by taking specific implementations as examples. However, those skilled in the art should know that the present invention is not limited to the specific embodiments listed, as long as it conforms to the spirit of the present invention, it should be included in the protection scope of the present invention.

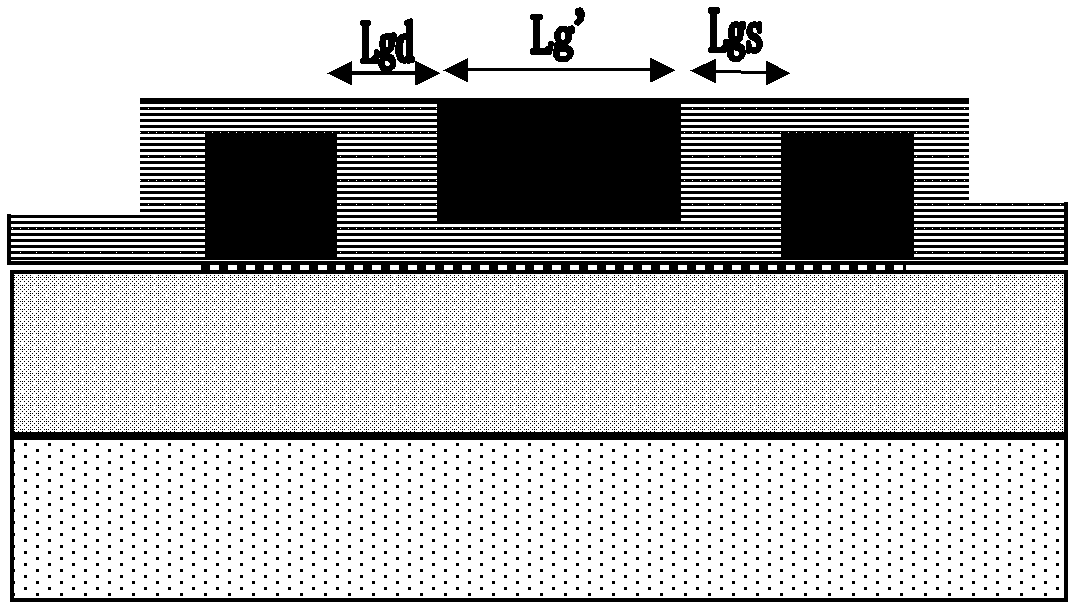

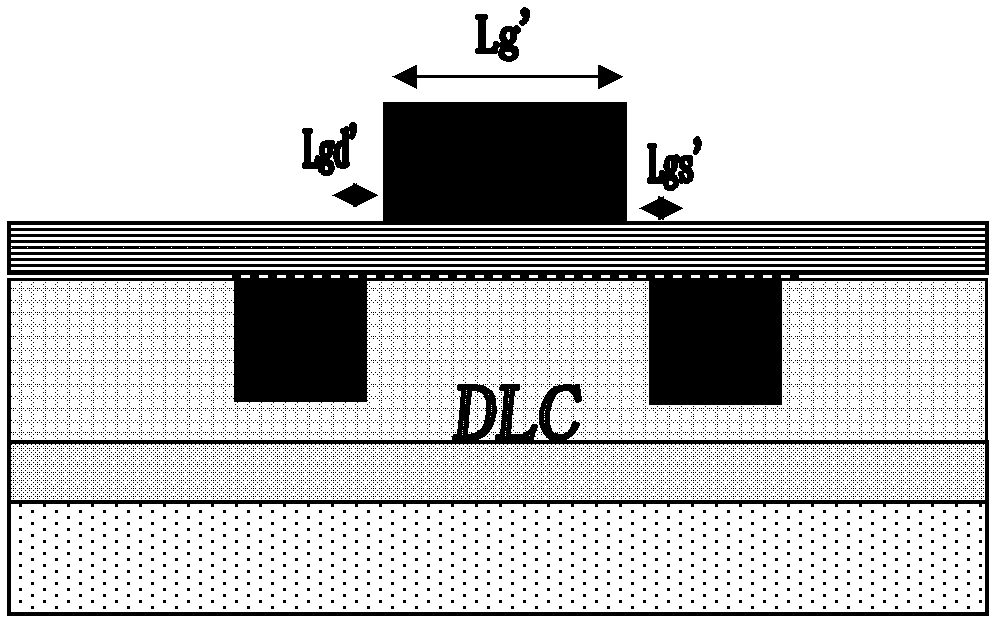

[0029] Basic principle of the present invention is as follows: diamond-like amorphous carbon (Diamond-like amorphous Carbon, abbreviated as DLC) thin film is a kind of very flat surface rich in Sp The amorphous carbon existence form of composition (reference: Michael Moseler.et al. The Ultrasmoothness of Diamond-like Carbon Surfaces. Science 3091545 (2005)). Diamond-like amorphous carbon has stable chemical properties, less surface trap charges and dangling bonds, and can form a weaker п bond with the graphene interface, which can obtain a better quality interfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com