Method for preparing DLC (diamond-like carbon) thick films by means of efficient magnetic filter plasma deposition

A plasma and metal plasma technology, used in the field of hard wear-resistant coatings, can solve the problems of difficult to achieve thickness, difficult to prepare thick films, soft hardness, etc., and achieve low friction coefficient, high bonding force, arc flow Size controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

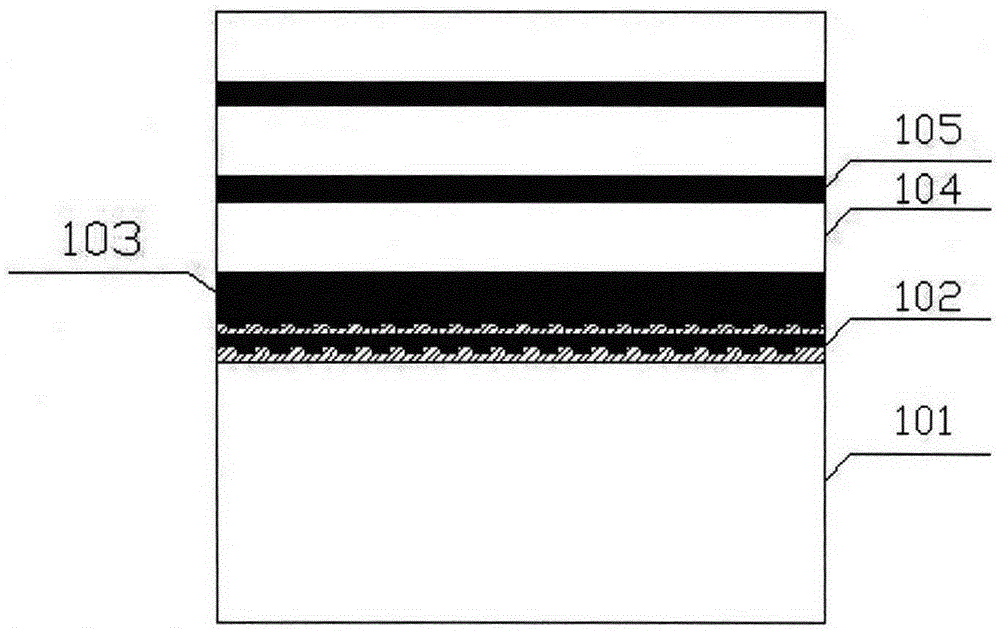

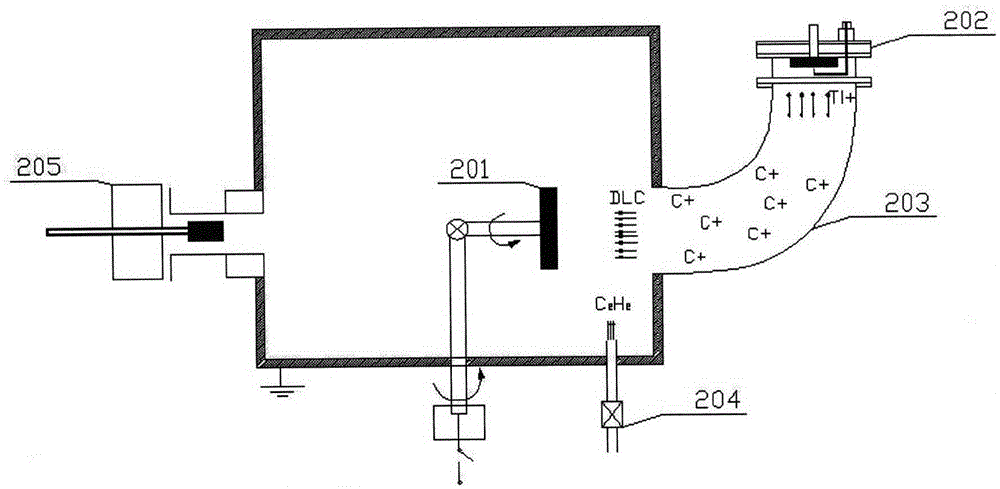

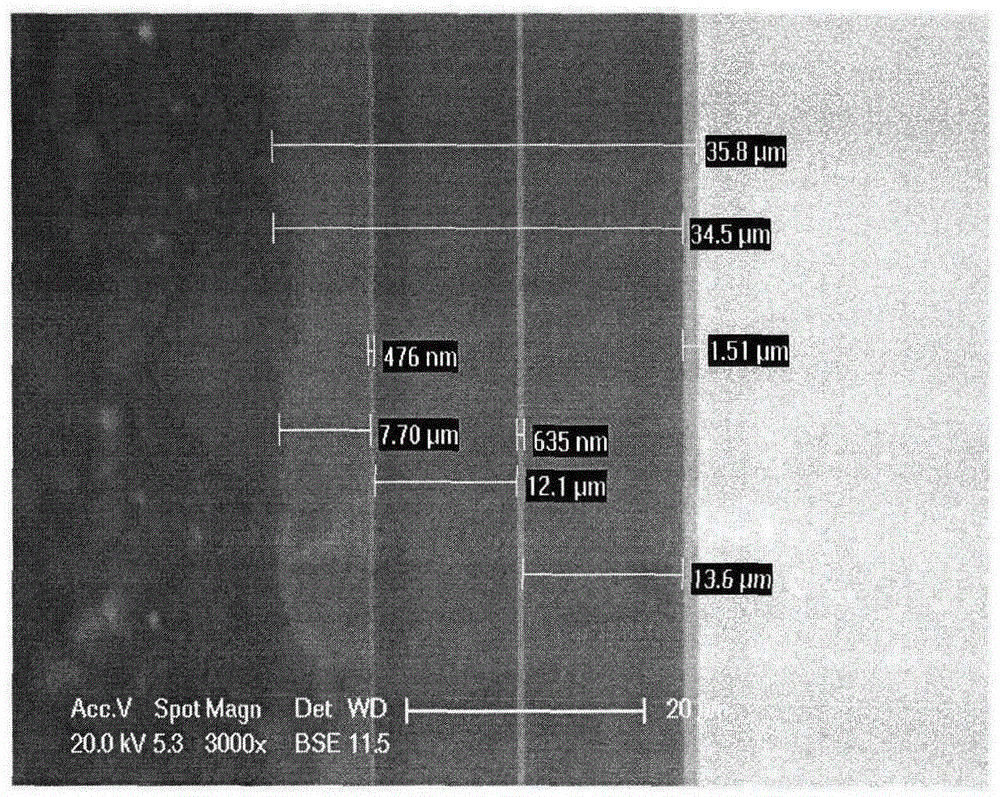

[0026] In conjunction with the description of the drawings, taking Ti ion source and Ti arc source as examples, the DLC thick film process flow of the present invention for preparing a metal carbide mosaic structure by magnetic filtration plasma deposition is introduced in detail. The implementation steps are as follows:

[0027] 1. Substrate polishing and cleaning:

[0028] (a) Polishing: use No. 400, No. 1000, and No. 1500 sandpaper to polish the φ25mm steel sample 101 in sequence, and then use diamond polishing paste and polishing flannelette to polish the smoothed steel sample.

[0029] (b) Cleaning: Use alcohol and acetone to ultrasonically clean the substrate steel sample.

[0030] 2. "Pinning" layer 102 preparation:

[0031] (a) Injection 1: fix the base material steel sample on the sample stage 201, and turn it to the injection target position to start injection. The implanted ion source is a pure Ti ion source with a purity of 99.9%, and the implantation conditions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com