Cathodic vacuum arc source film depositing device and method for depositing film

A thin film deposition device and vacuum arc technology, applied in vacuum evaporation plating, ion implantation plating, metal material coating technology, etc., can solve problems such as difficult to meet requirements, and achieve smooth surface, dense film structure, and uniform area big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

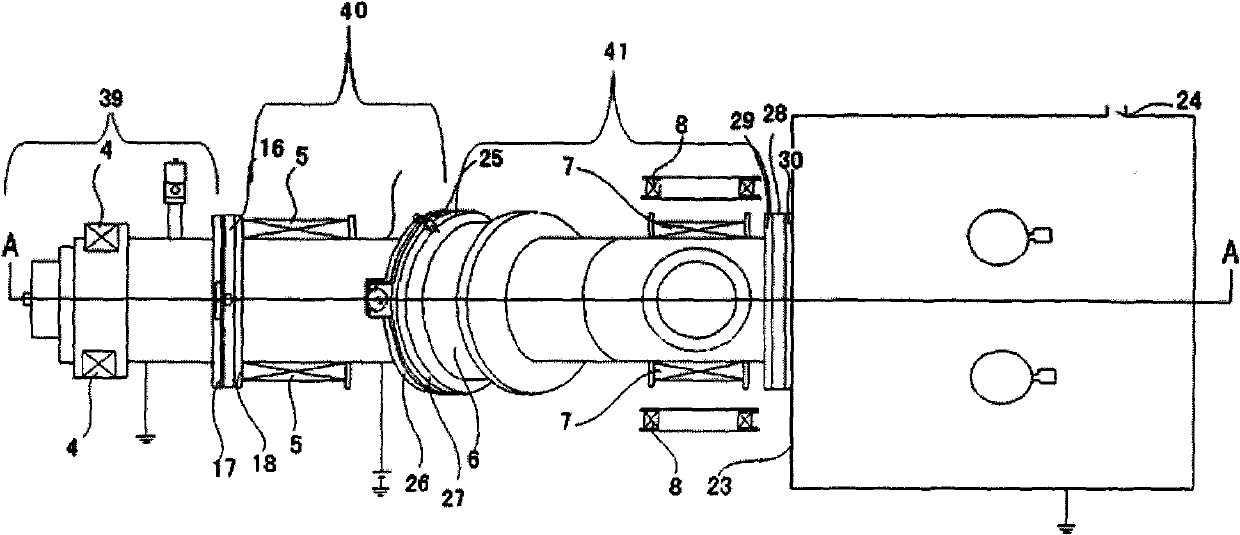

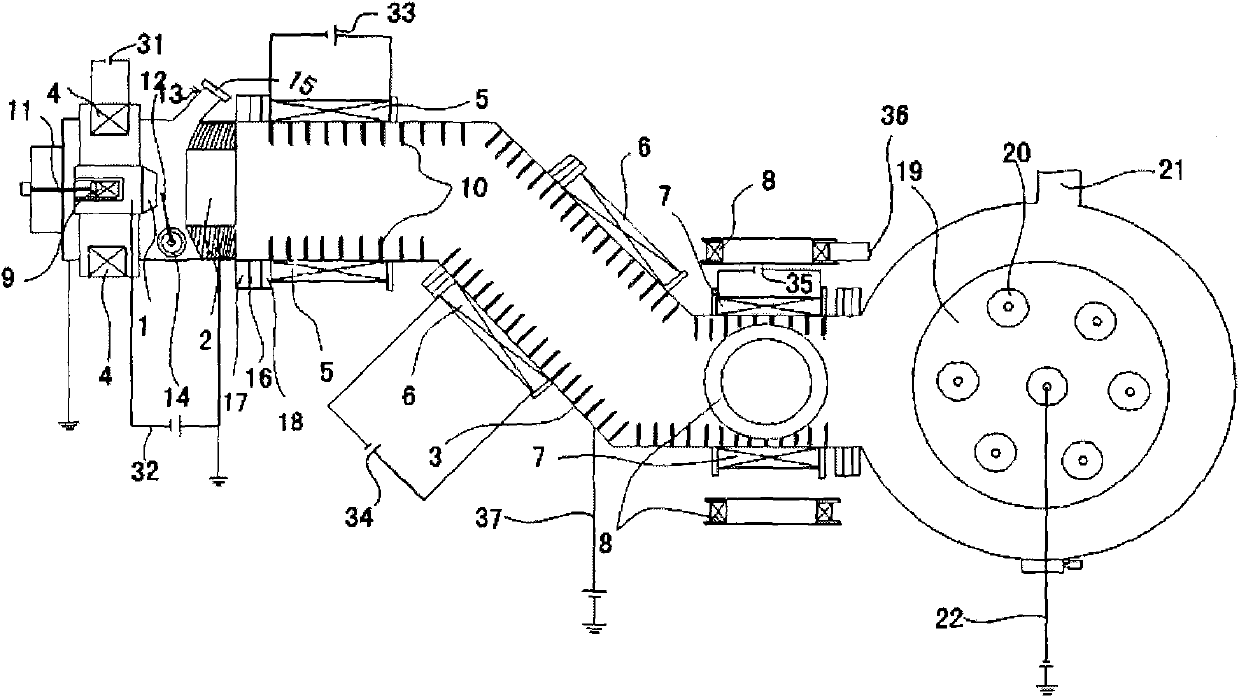

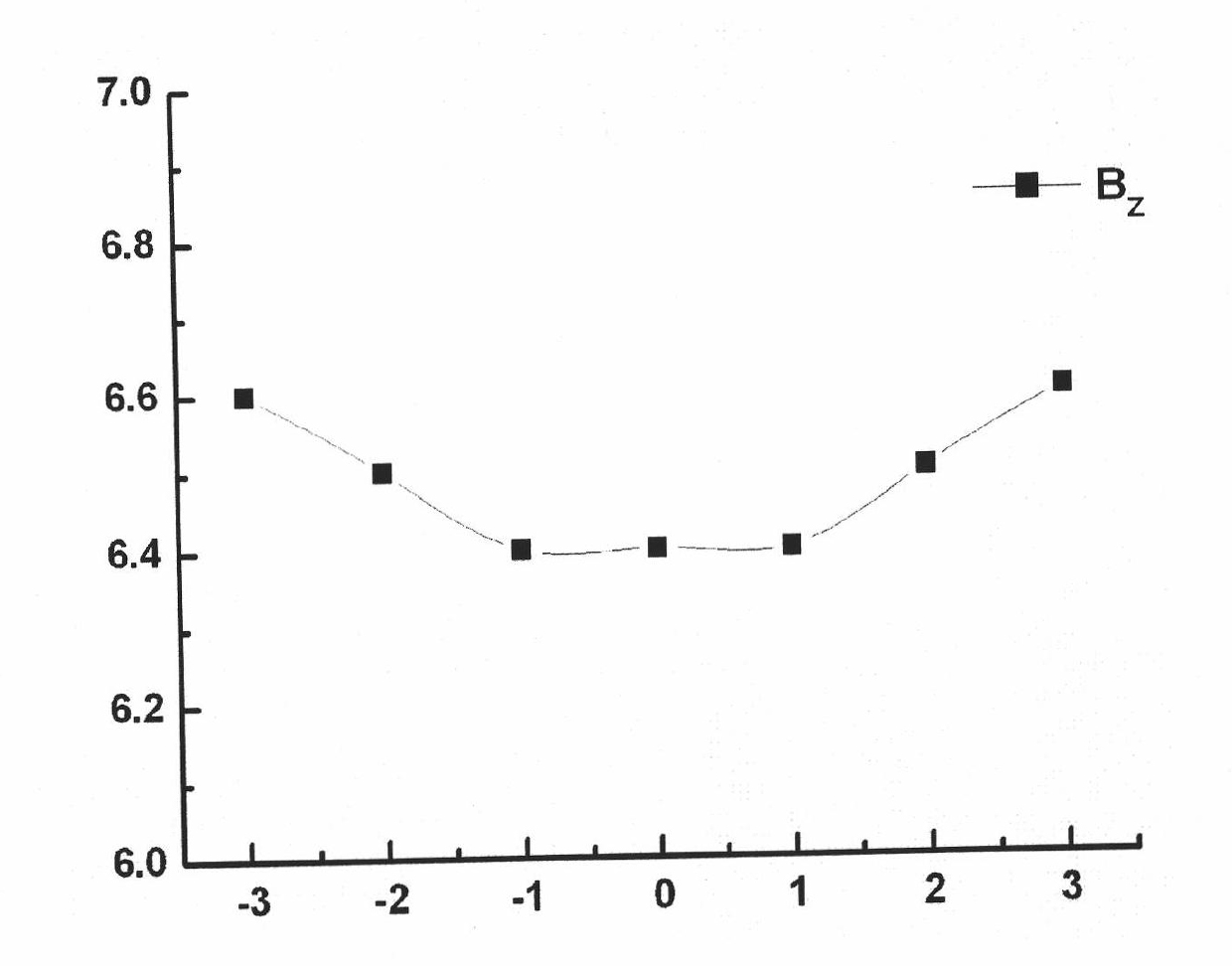

[0034] Figure 1 to Figure 7 Shown is the structural representation of the present invention.

[0035] The reference signs therein are: cathode 1, anode 2, elbow 3, arc source coil 4, pulling coil 5, bending coil 6, output coil 7, scanning coil 8, permanent magnet 9, grid baffle 10, Threaded rod 11, trigger electrode 12, gas channel 13, pneumatic valve 14, observation window 15, insulating washer 16, stainless steel ring 17, stainless steel ring 18, large disk 19, small disk 20, air inlet 21, bias power supply 22, film deposition Vacuum chamber 23, vent port 24, insulating gasket 25, stainless steel ring 26, stainless steel ring 27, insulating gasket 28, stainless steel ring 29, stainless steel ring 30, arc source coil DC power supply 31, arc pulse power supply 32, pull coil DC power supply 33 , bending coil DC power supply 34, output coil D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com