Making methods and apparatuses of flexible substrate circuit board and metal pinning layer

A technology of flexible substrates and metal nails, applied in the electronic field, can solve the problems of weak anti-peel strength, decreased bonding strength, and insufficient bonding force of the film layer, and achieve the effect of good bonding force and enhanced anti-peeling strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

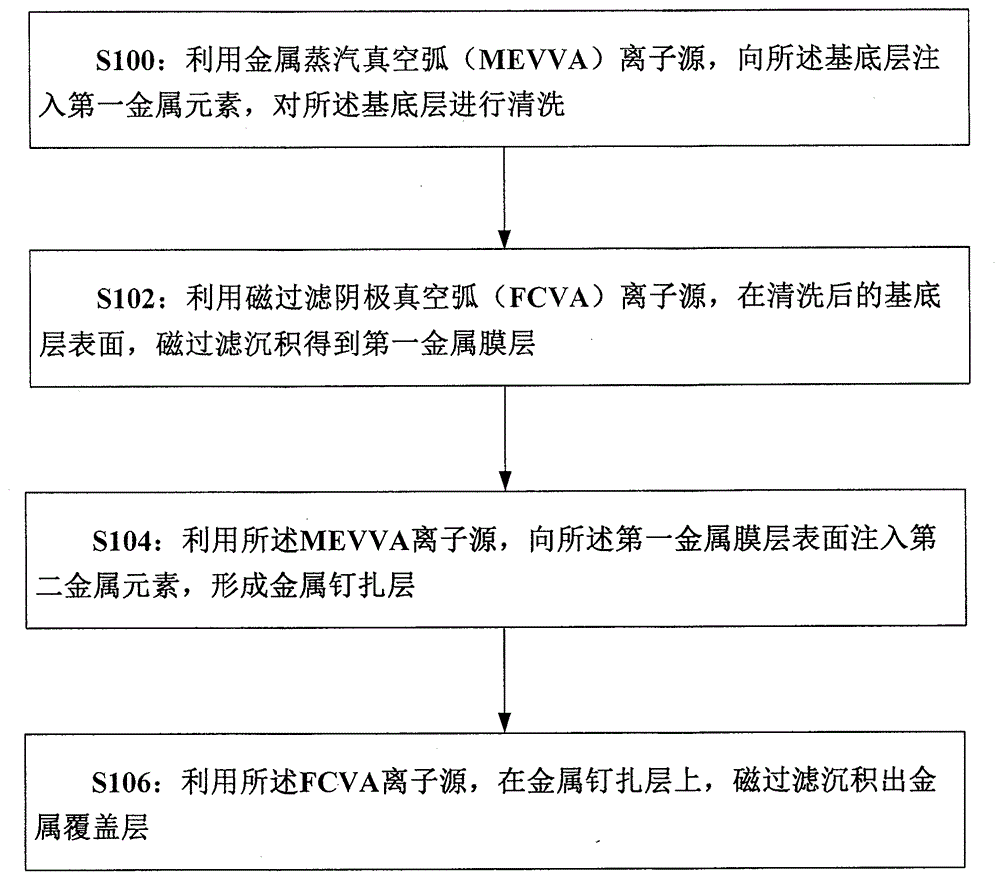

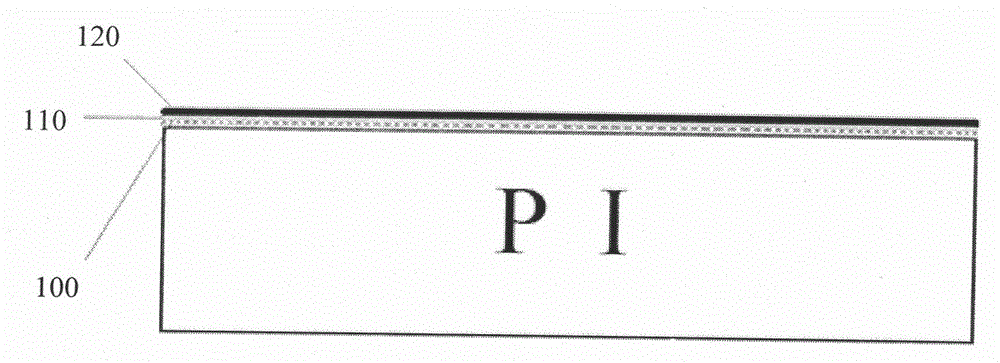

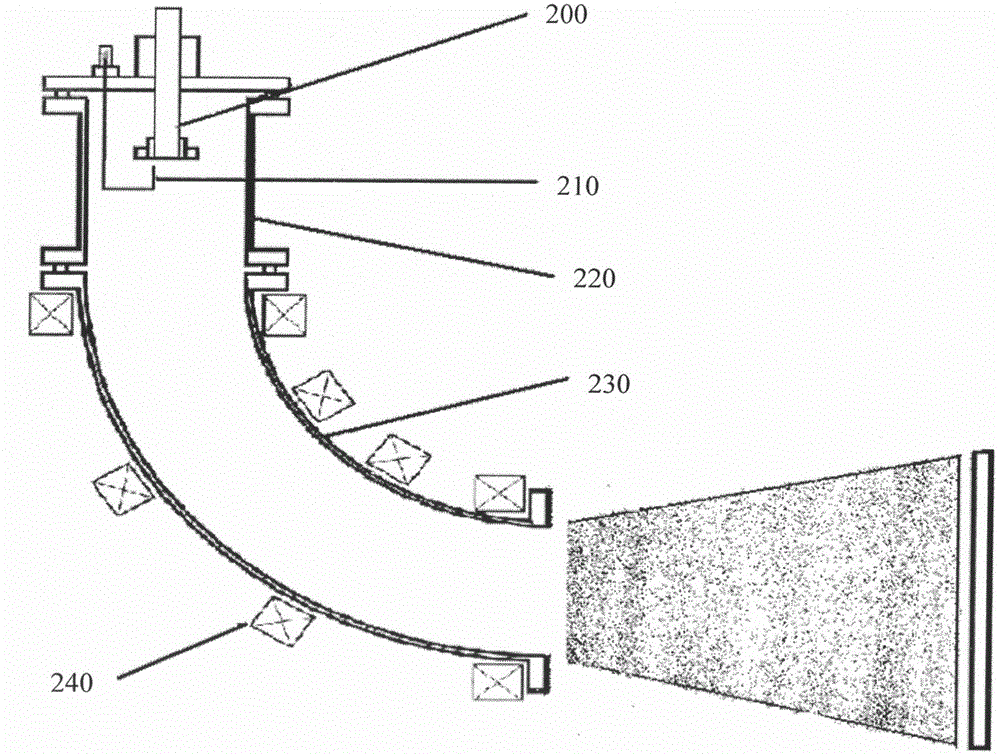

[0047] refer to figure 1 , which shows the preparation method of the metal pinning layer of this embodiment, the preparation method includes the following steps:

[0048]S100: Using a metal vapor vacuum arc (MEVVA) ion source, injecting a first metal element into the base layer to clean the base layer.

[0049] Among them, this step is the cleaning process of metal ion implantation in the early stage. The polyimide film is implanted with high-energy metal ions, which can sputter off the surface to absorb dust and gas, etc., and improve the cleanliness of the surface. In addition, the MEVVA ion source implants metal elements into the polyimide. During the implantation process, the metal elements have certain energy, which can have a certain sputtering effect on the physically adsorbed or chemically adsorbed impurities on the surface of the polyimide film, and can A shallow implanted metal doped layer is formed.

[0050] In addition, before depositing the metal pinning layer, ...

example 1

[0115] Example 1: (no pinning layer structure)

[0116] Using the PI 100HN polyimide film produced by DuPont of the United States as the base material, the polyimide film layer is treated on both sides in the following manner:

[0117] 1) The Cu film transition layer was deposited by magnetic filtration, the conditional arc current was 100A, the magnetic field current of the elbow was 2.0A, and the deposition thickness was 20nm.

[0118] 2) Electroplating in a copper sulfate solution to form a copper film with a thickness of 20 μm.

example 2

[0119] Example 2: (Cu metal is selected as the structural element of the pinning layer)

[0120] 1) Cleaning: ion implantation of Cu element conditions: implantation high voltage 6kV, implantation beam intensity 3mA, implantation dose 3×10 15 ;

[0121] 2) Magnetic filtration deposition Cu film conditions: arc current 100A, elbow magnetic field current 2.0A, deposition thickness 8nm;

[0122] 3) Perform Cu ion implantation on the Cu thin layer to form a pinning layer Conditions: accelerating voltage 12kV, beam current 5mA, implant dose 3×10 15 / cm 2 ;

[0123] 4) Covering: magnetic filtration deposited Cu film covering layer conditions: arc current 100A, elbow magnetic field current 2.0A, deposition thickness 20nm;

[0124] 5) Finally, electroplating in a copper sulfate solution to form a copper film with a thickness of 20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com