Ion implanted composite coating film apparatus

A composite coating and ion implantation technology, applied in the field of ion implantation composite coating equipment and multi-functional composite coating equipment, can solve problems such as single function, and achieve the effect of reducing equipment manufacturing cost, novel equipment design, and reasonable and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

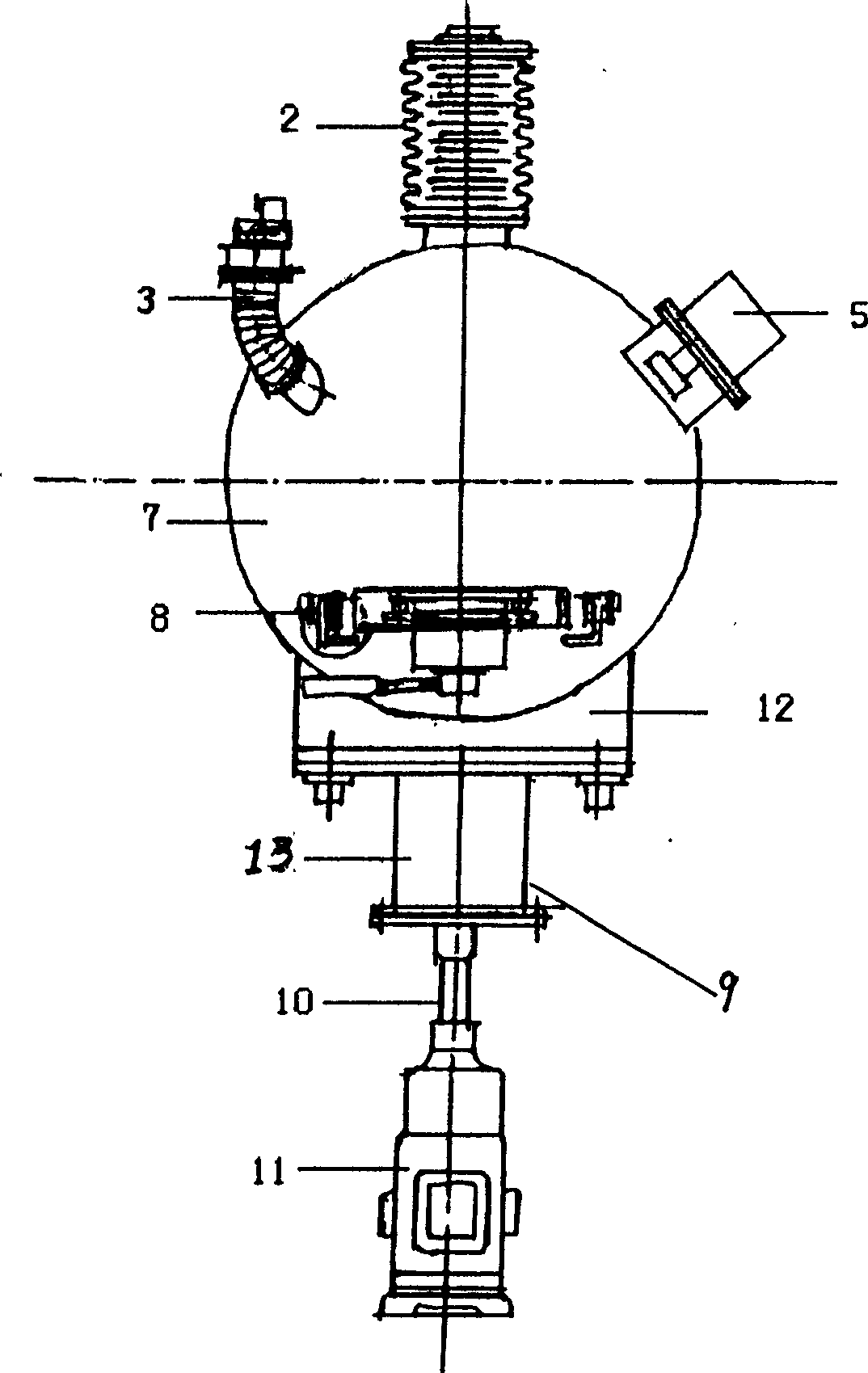

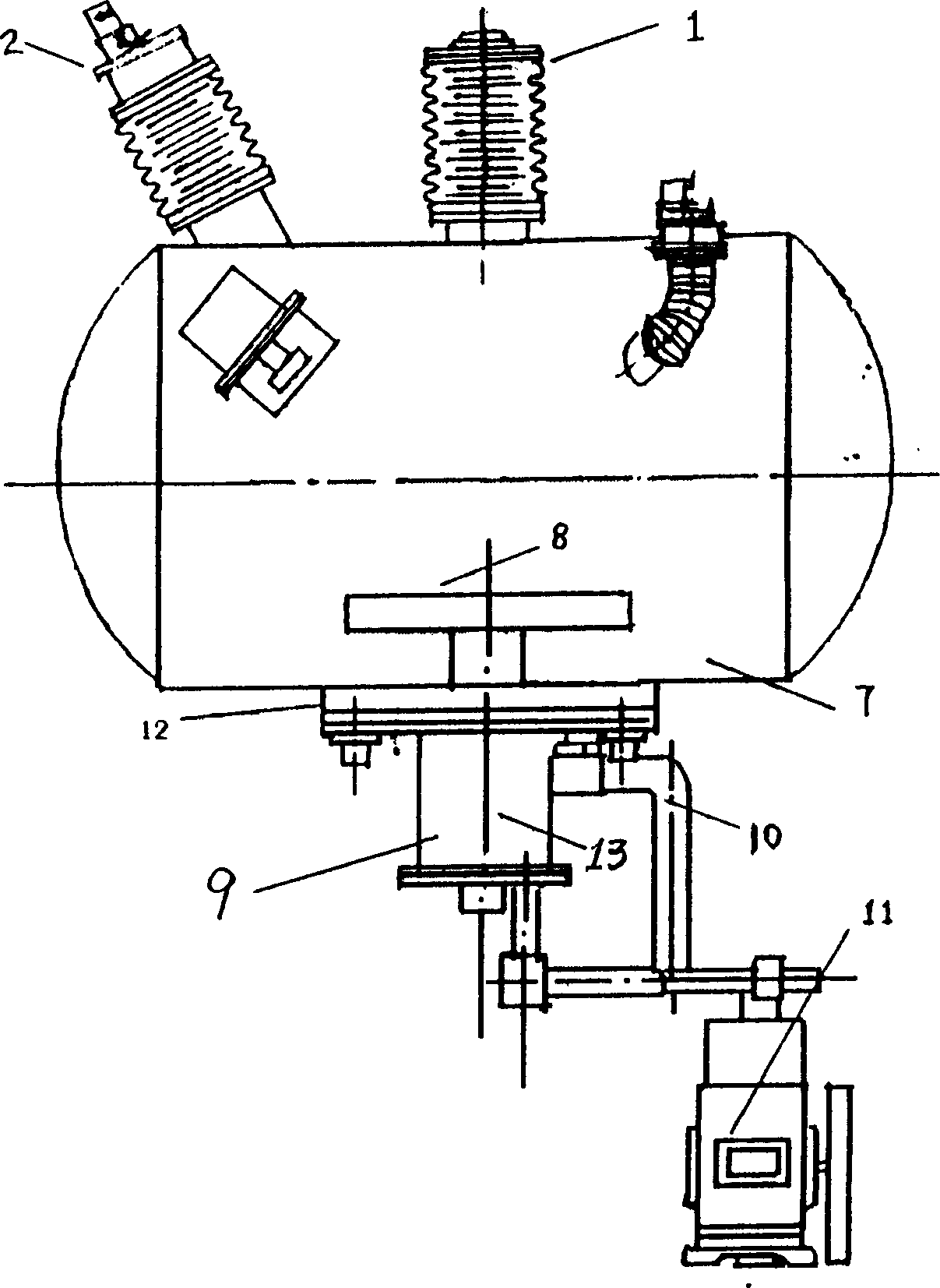

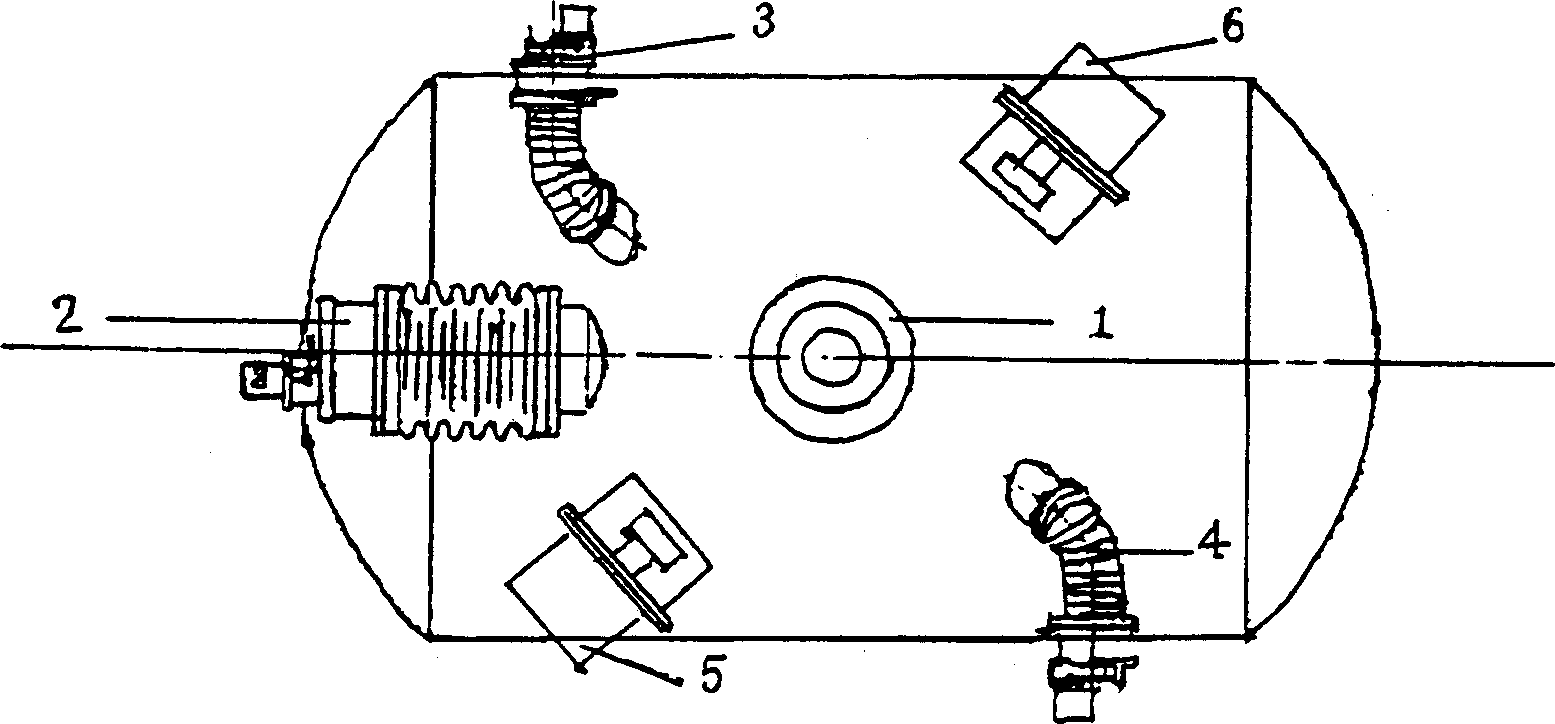

[0018] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes: a gas ion source 1, a metal ion source 2, two DC magnetic filtered arc ion plating sources 3 and 4, a DC magnetron sputtering target source 5, an intermediate frequency pulse magnetron sputtering target source 6, a vacuum Chamber 7, multi-purpose sample stage 8 and vacuum pumping system 9. Its connection mode is: gas ion source 1, metal ion source 2, DC magnetron sputtering target source 5, intermediate frequency pulse magnetron sputtering target source 6, and two sets of DC magnetic filter arc ion plating sources 3 and 4 shared by six sources A vacuum chamber 7, and fixed on the shell of the composite coating machine, the gas ion source 1 is vertically located in the middle of the upper part of the vacuum chamber 7, and the metal ion source 2 is located on one side of the gas ion source 1, and is obliquely inserted in the upper part of the vacuum chamber 7. The center line is 62° to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com