Method for filtering and purifying hydraulic oil

A technology for filtering and purifying hydraulic oil, which is applied in fluid pressure actuating devices, fluid pressure actuating system components, mechanical equipment, etc. It can solve problems such as failure to realize automatic control, insufficient filtration accuracy, and need for frequent cleaning, etc., to achieve improved life, improve filtration efficiency, and realize the effect of time estimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

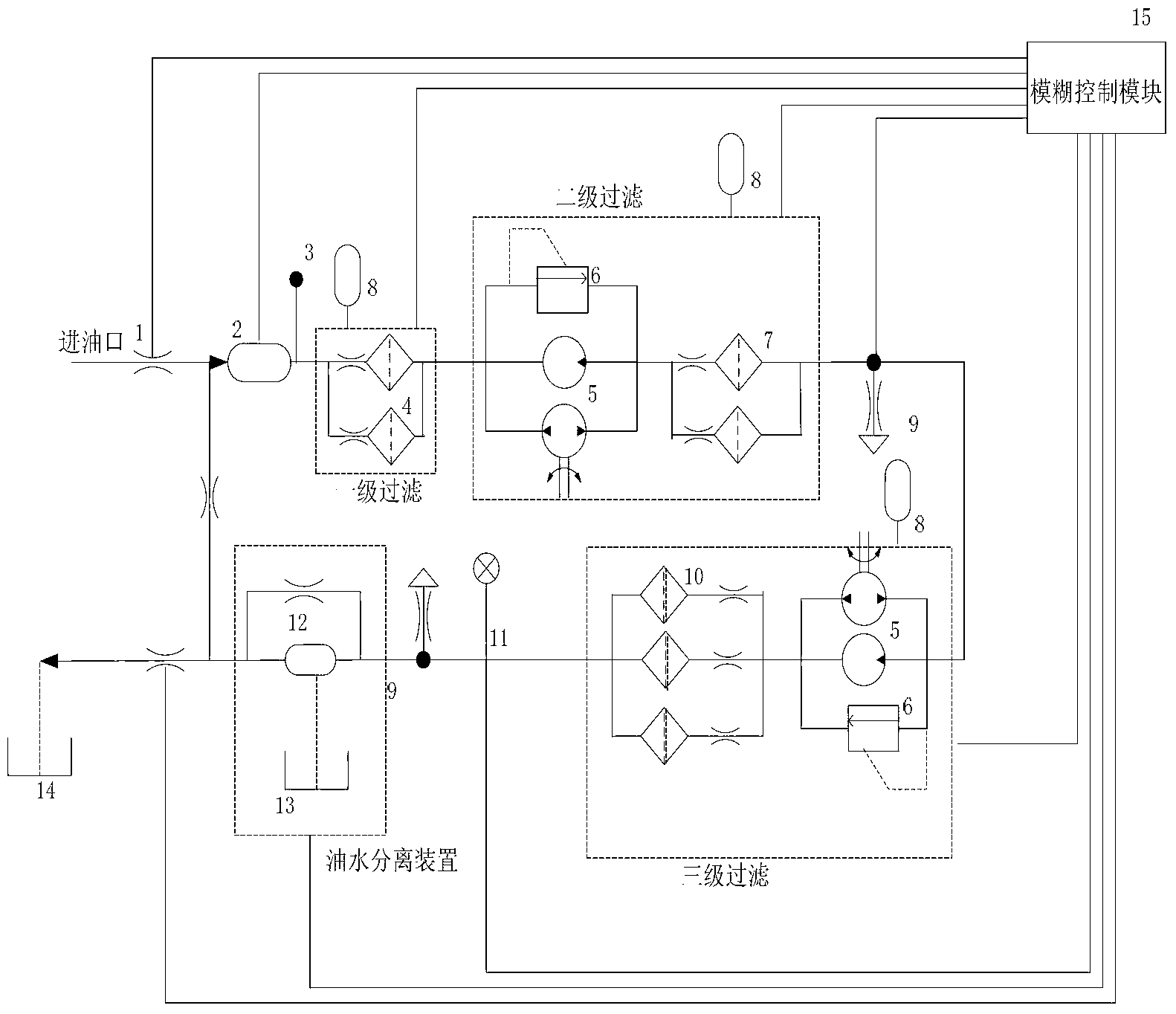

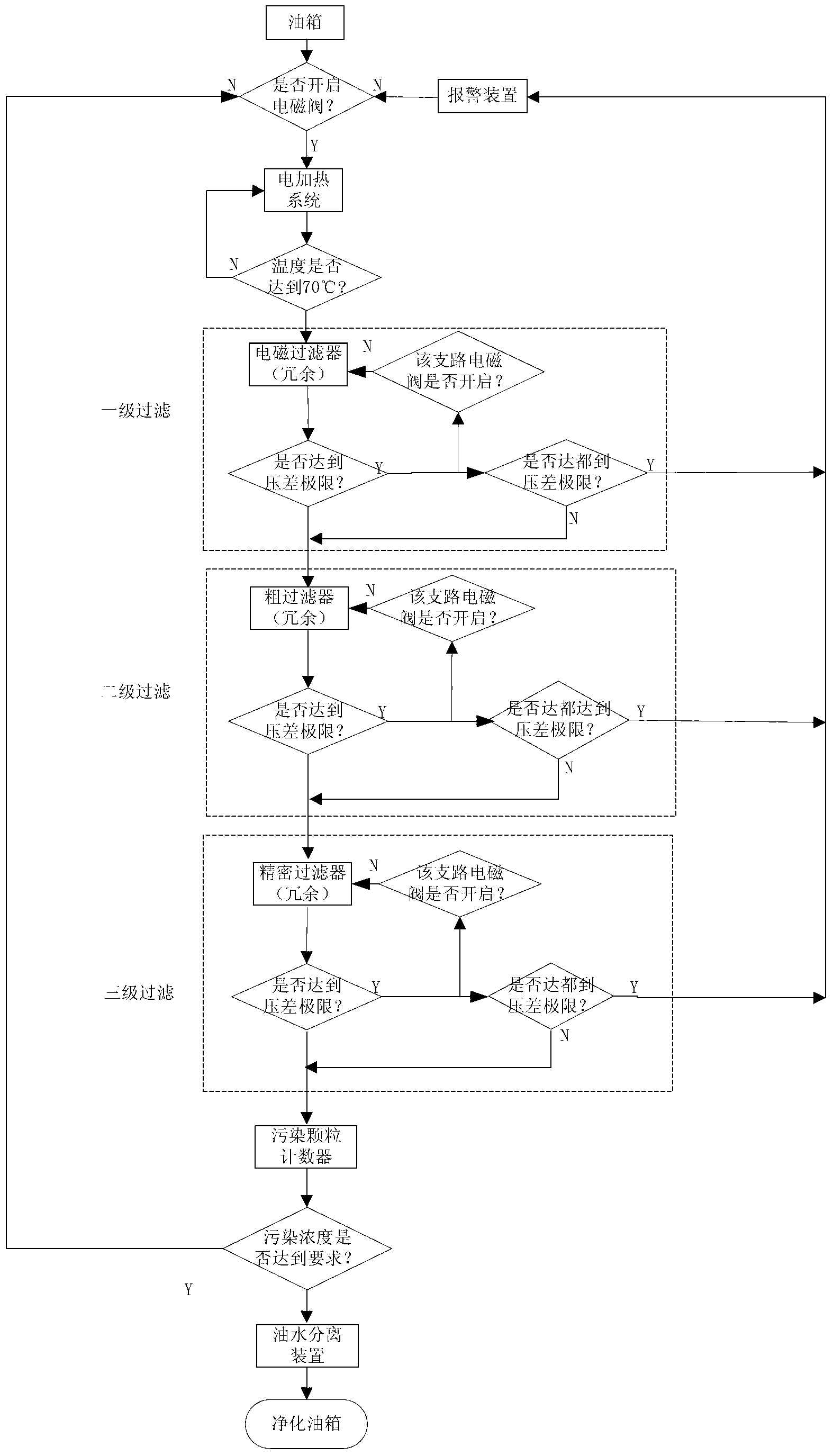

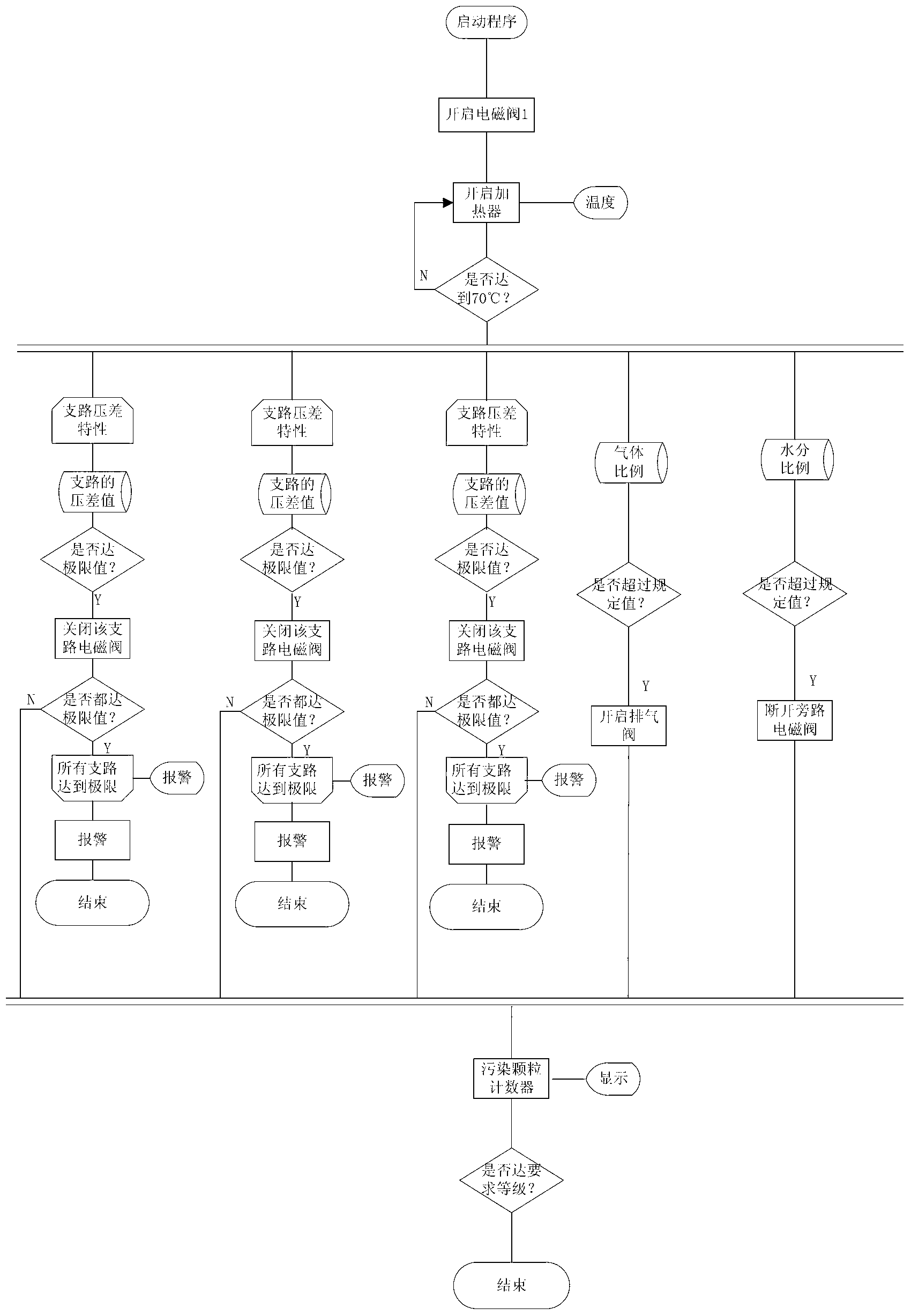

[0028] The present invention is used for the purification method of hydraulic components and system polluted oil, and the filtering device used is as figure 1 As shown, the specific purification process is as follows figure 2 Shown: Below in conjunction with accompanying drawing, this method is described in further detail.

[0029] Step 1: Apply electric heating system to heat the oil

[0030] The electric heating system includes: an electric heater 2 , a thermometer 3 and a fuzzy control module 15 . The electric heater 2, which is a common temperature-adjustable electric heater with the function of heating oil, is installed near the oil inlet and connected to the fuzzy control module 15; the fuzzy control module 15 , it is an integrated software with fuzzy control function for multiple hydraulic components and parameters. The filter system realizes the function of fuzzy control, which can automatically handle the valve opening and closing, alarm, system heating, exhaust a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com