Method and device for vacuum arc vapour deposition

A vacuum arc and evaporation technology, which is applied in vacuum evaporation plating, circuits, discharge tubes, etc., can solve the problems that it is impossible to form a thin film and obtain a uniform film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

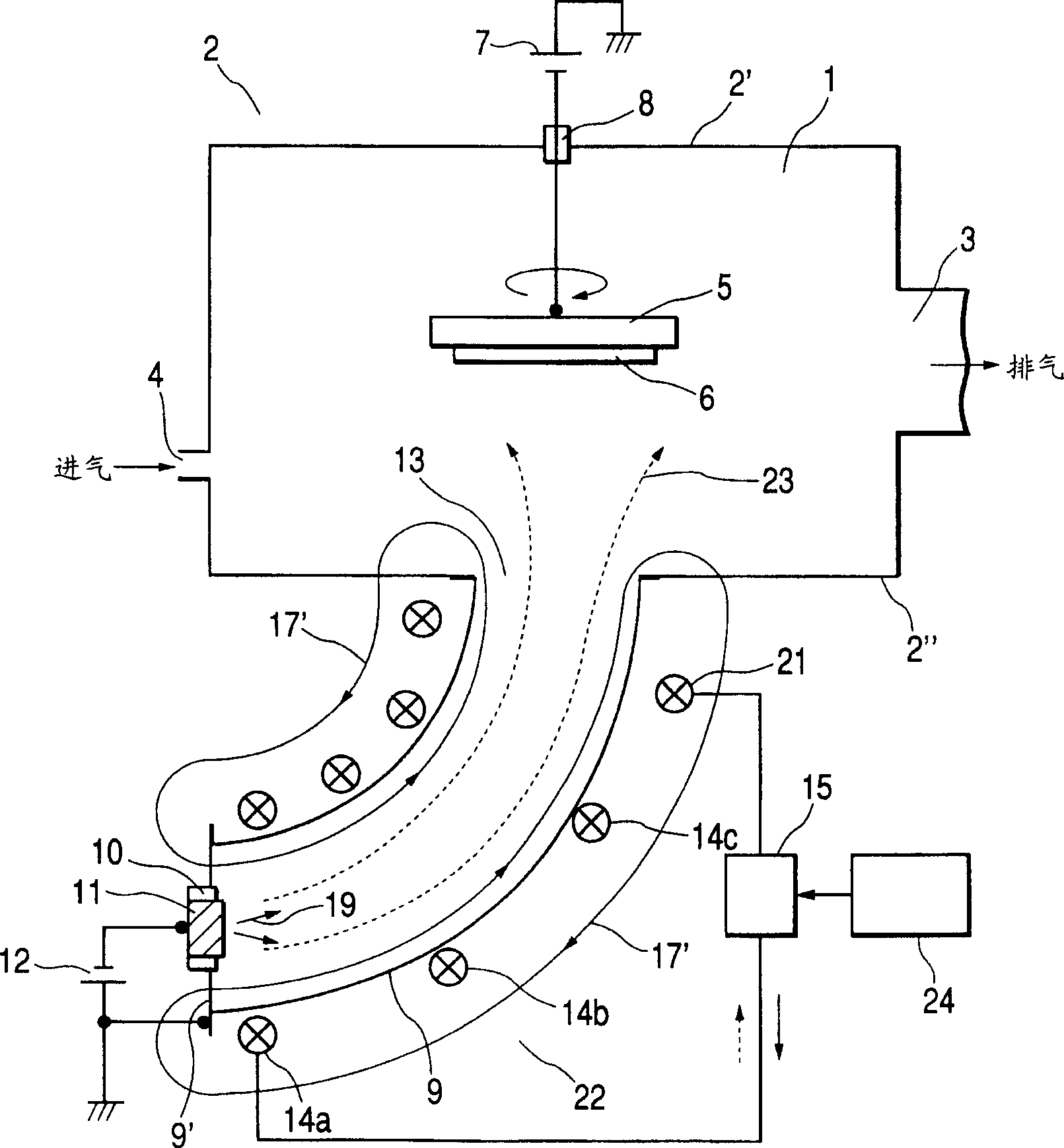

[0155] Refer to the attached figure 1 -8 An embodiment of the present invention will be described.

[0156] figure 1 for with Figure 9 The plan view of the corresponding vacuum arc evaporation apparatus in the vacuum arc evaporation apparatus.

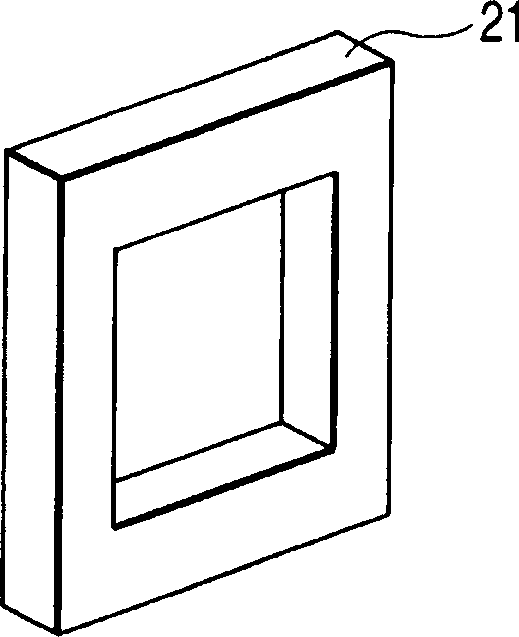

[0157] exist figure 1 , replace with electromagnetic coil 21Figure 9 In the electromagnetic coil 14d as the end magnet. This electromagnetic coil 21 is larger than the other electromagnetic coils 14a-14c.

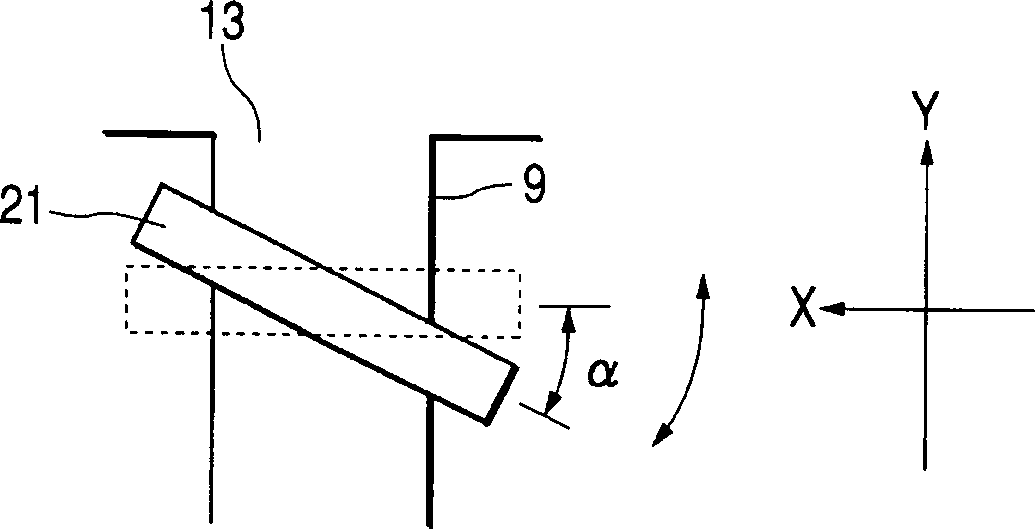

[0158] The shape of the electromagnetic coil 21 is similar to figure 2 Medium rectangular frame shown in perspective view. In the representation installed to Figure 3A and 3B In the plan view and right side view of the electromagnetic coil on the tube in , the X-axis direction represents the horizontal direction (the right side is the "positive direction"), the Y-axis direction is the front-back direction (the rear side is the "positive direction"), and the Z-axis direction The direction is the vertical direction (uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com