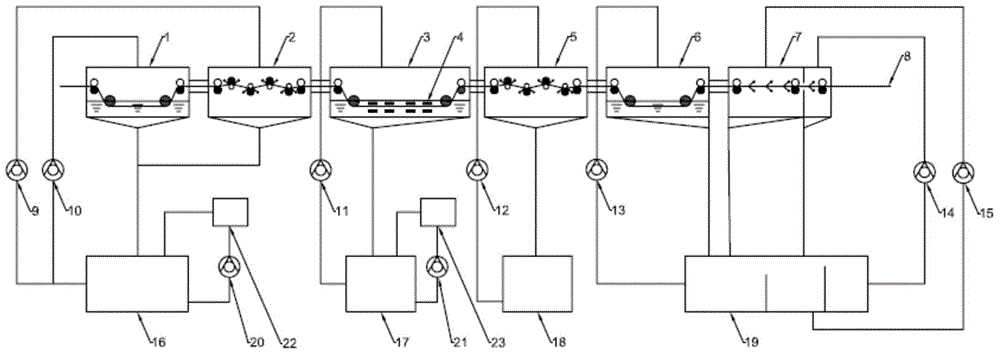

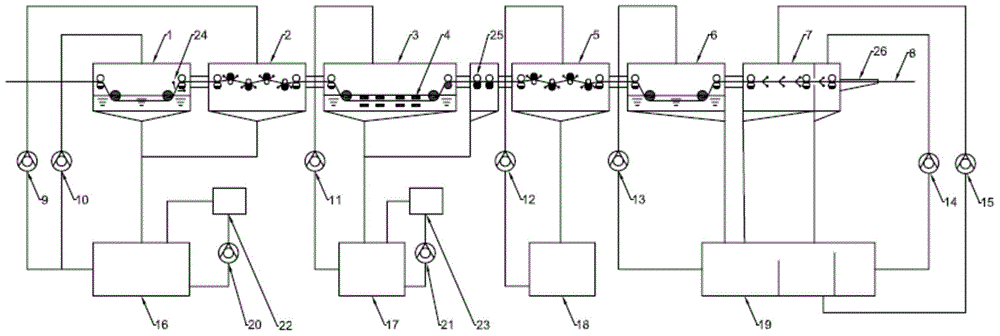

Improved silicon steel plate belt surface cleaning device and cleaning method

A technology for surface cleaning and silicon steel plate strips, which is applied in the direction of cleaning methods using tools, cleaning methods using liquids, cleaning methods and utensils, etc., which can solve the clogging of alkali brushing nozzles, water overflow on the outlet side of the water rinsing tank, and steel belts. Problems such as poor surface cleaning quality to achieve the effect of avoiding nozzle clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The typical control process of the improved silicon steel strip surface cleaning device is shown in Table 1:

[0032]Table 1 Typical control process of silicon steel strip surface cleaning device

[0033] serial number

[0034] After adopting the improved silicon steel strip surface cleaning device and cleaning process, the strip surface cleanliness is shown in Table 2.

[0035] Table 2 adopts cleaning device of the present invention and strip surface cleaning effect comparison table before and after the process

[0036] serial number

[0037] According to the above embodiments, it can be seen that the present invention improves the surface cleaning quality of the silicon steel sheet, ensures the cleanness of the steel strip surface in the furnace, helps reduce the probability of furnace roll nodulation, and avoids the impact on the peripheral equipment of the cleaning device and the safety environment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com