Electromagnetic filter

An electromagnetic filter and filter technology, applied in the fields of filtration and separation, chemical instruments and methods, separation methods, etc., can solve the problems of low backwashing efficiency, large water consumption, difficult to meet, etc., and achieve uniform magnetic distribution and high magnetic field strength. , The effect of high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

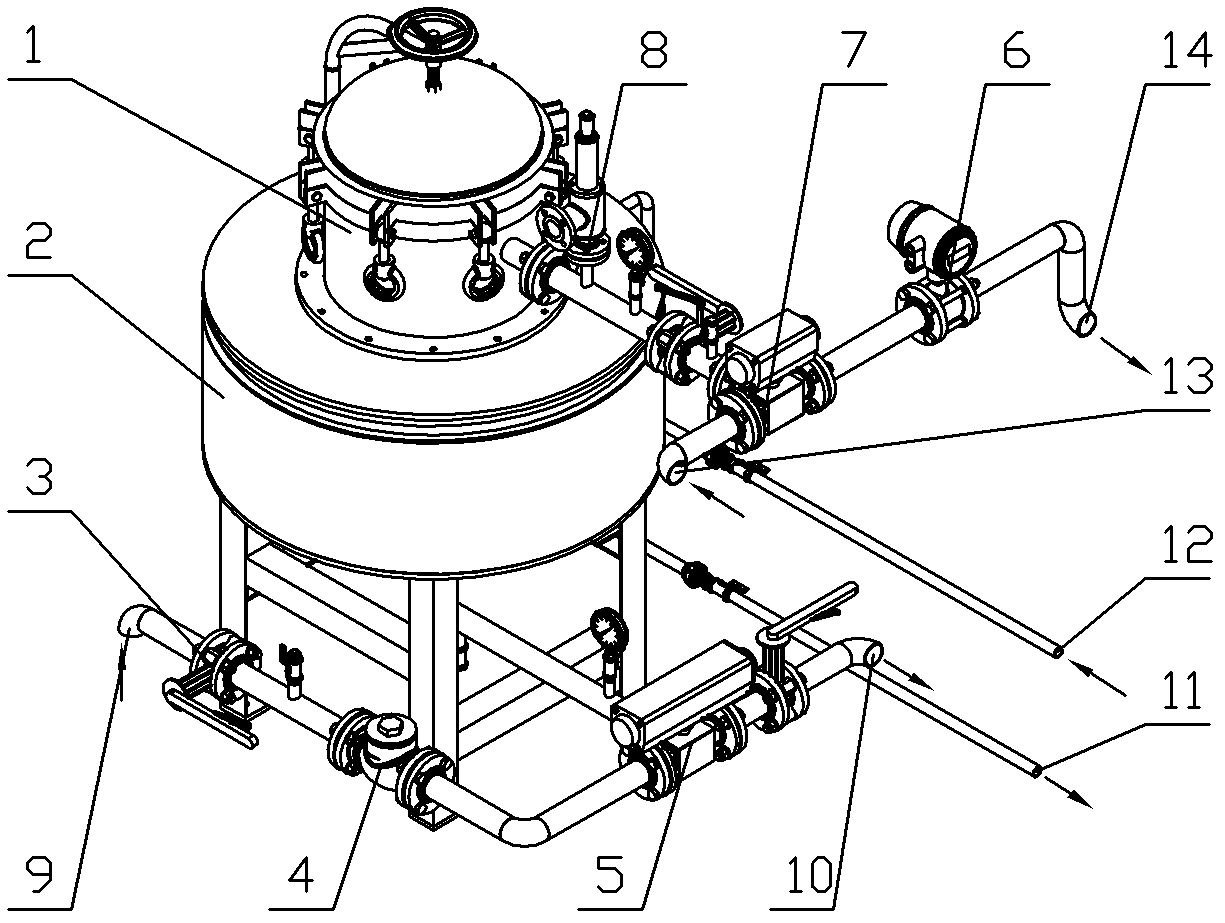

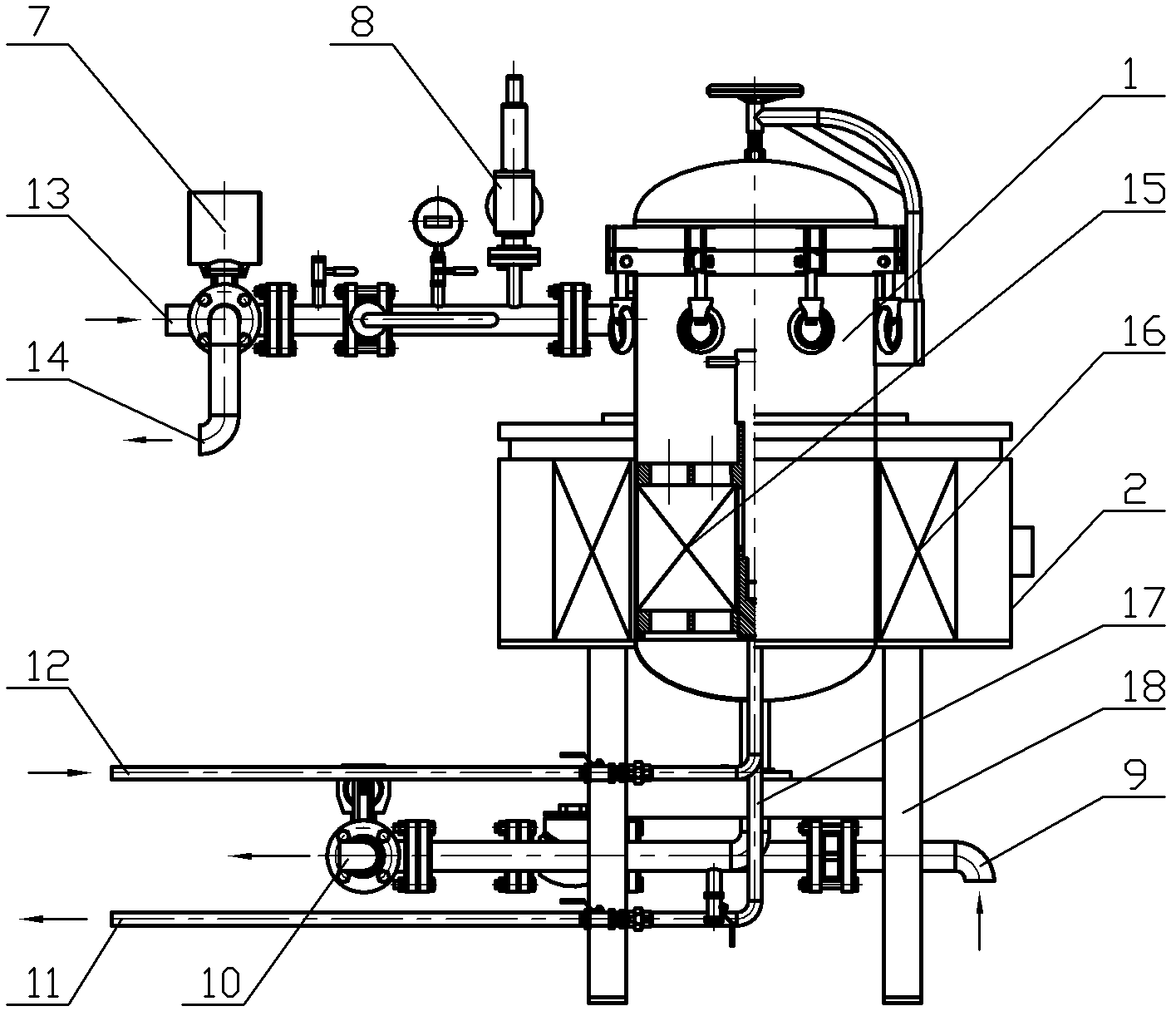

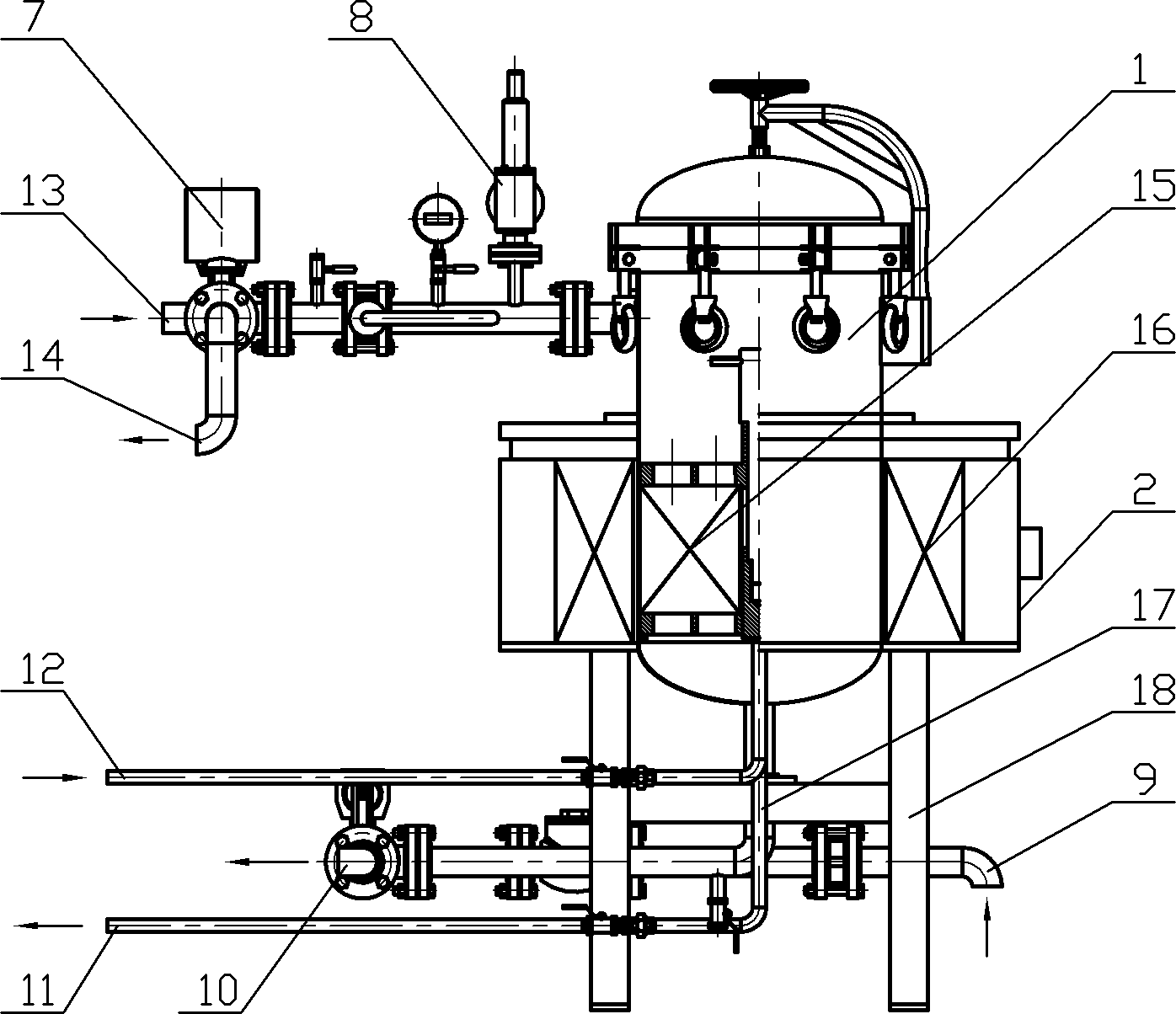

[0014] figure 1 , figure 2 Including filter 1, electromagnetic coil housing 2, manual butterfly valve 3, stop valve 4, first pneumatic three-way ball valve 5, electromagnetic flowmeter 6, second pneumatic three-way ball valve 7, safety valve 8, liquid inlet 9 , Slag outlet 10, cooling water outlet 11, cooling water inlet 12, backwash inlet 13, liquid outlet 14, magnetic grid 15, electromagnetic coil 16, cooling water pipe 17, bracket 18, etc.

[0015] Such as figure 1 , figure 2 As shown, the present invention is an electromagnetic filter, comprising a filter 1 with a liquid inlet 9 and a liquid outlet 14, a magnetic conduction grid 15 is arranged in the cylinder of the filter 1, and the casing of the filter 1 is An electromagnetic coil housing 2 is provided, and a bracket 18 is fixed on the bottom of the electromagnetic coil housing 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com