Louver fin and heat exchanger adopting louver fins

A technology of louver fins and heat exchangers is applied in the field of fins of heat exchangers, which can solve the problems of the reduction of the energy efficiency ratio of the tube-fin heat exchangers, the easy blockage of the openings of the louvers, and the decrease of the heat exchange capacity of the products, and achieves the Significant economic and social benefits, simple structure, and the effect of saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

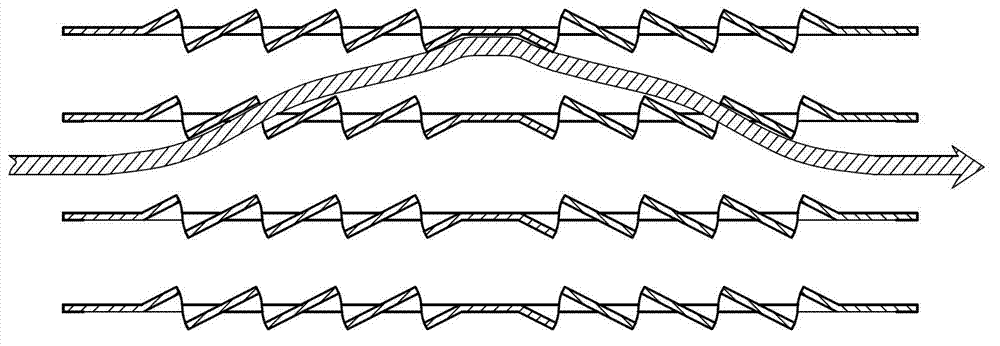

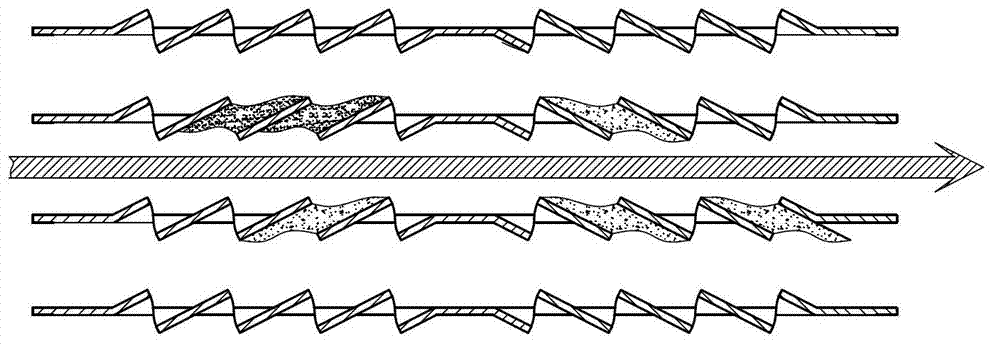

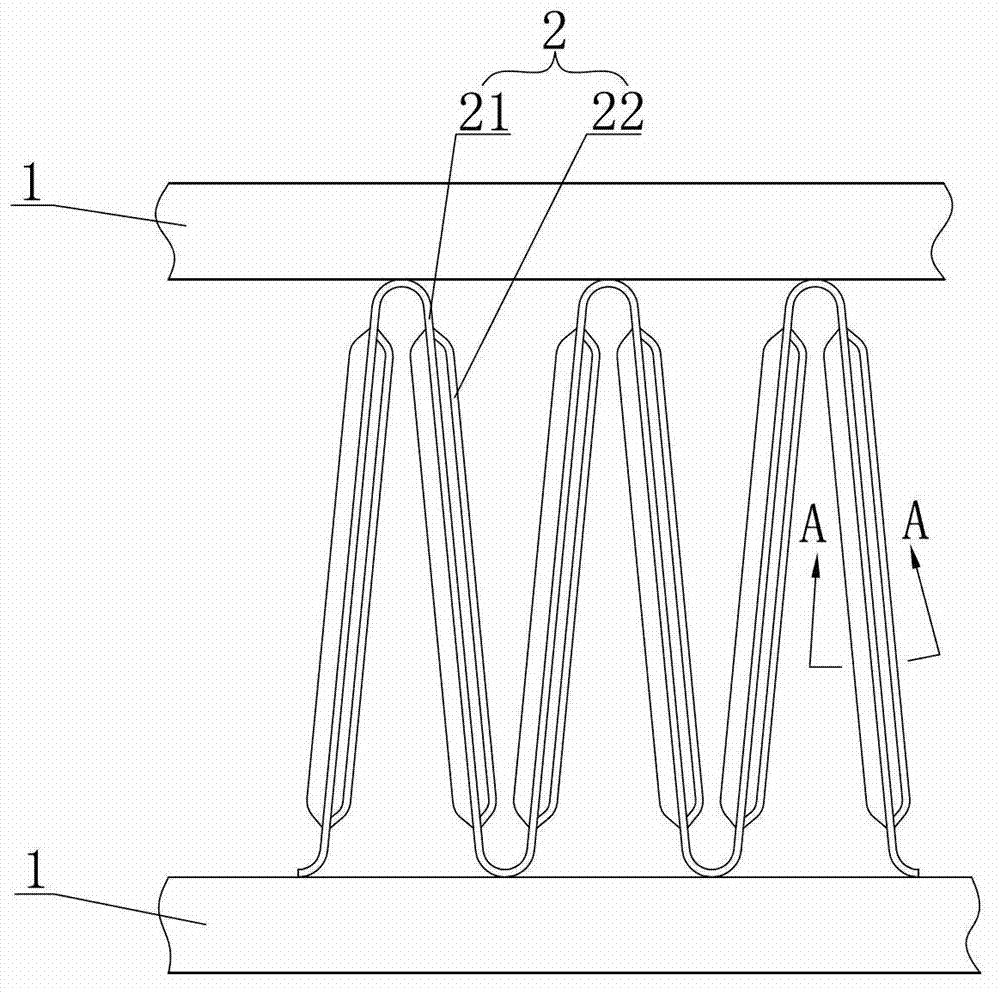

[0033] refer to Figure 4 , 5 , the louver fin of the present embodiment includes a substrate 21 and a window fin 22 formed on the substrate 21, an airflow channel 3 is formed between adjacent window fins 22, and the substrate 21 is divided into inlet portions 23 according to the air flow direction , windward part 24, reversing part 25, leeward part 26 and outlet part 27, above-mentioned window fin 22 is formed in windward part 24 and leeward part 26, and the window wing 22 window opening angle α of windward part 24 and the window of leeward part 26 The fins 22 have the same window opening angle β, and the window opening directions are opposite, and the inlet portion 23 is provided with a guide protrusion 28 . Generally, the airflow enters the fins from the inlet 23, and after passing through the guide protrusions 28, most of the dust in the air is blocked or bounced off, and the bounced dust directly enters the direct airflow, and the airflow bypasses the guide After the fl...

Embodiment 2

[0039] refer to Figure 6, the solution of this embodiment is substantially the same as that of Embodiment 1, except that: the diversion protrusion 28 is V-shaped, similarly, the V-shaped diversion protrusion also has two slopes, its effect can refer to Embodiment 1.

Embodiment 3

[0041] refer to Figure 7 , the scheme of this embodiment is roughly the same as that of Embodiment 1, the difference is that the diversion protrusion 28 is arc-shaped, and similarly, although the arc-shaped diversion protrusion does not have a slope, its arc surface can also reach The technical effect of the trapezoidal diversion protrusion in the first embodiment.

[0042] From the description of the above embodiment, it can be known that the shape of the diversion protrusion 28 includes but is not limited to arc shape, V shape or trapezoid, and can also be other shapes, such as square, etc., but in terms of effect, it has a slope or an arc surface. The implementation effect of the deflector protrusion is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com