Branch controllable titanium dioxide nanotube array thin film and preparation method thereof

A nanotube array, titanium dioxide technology, applied in nanostructure manufacturing, chemical instruments and methods, nanotechnology and other directions, to achieve the effects of wide application prospects, wide adjustable range, and controllable morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

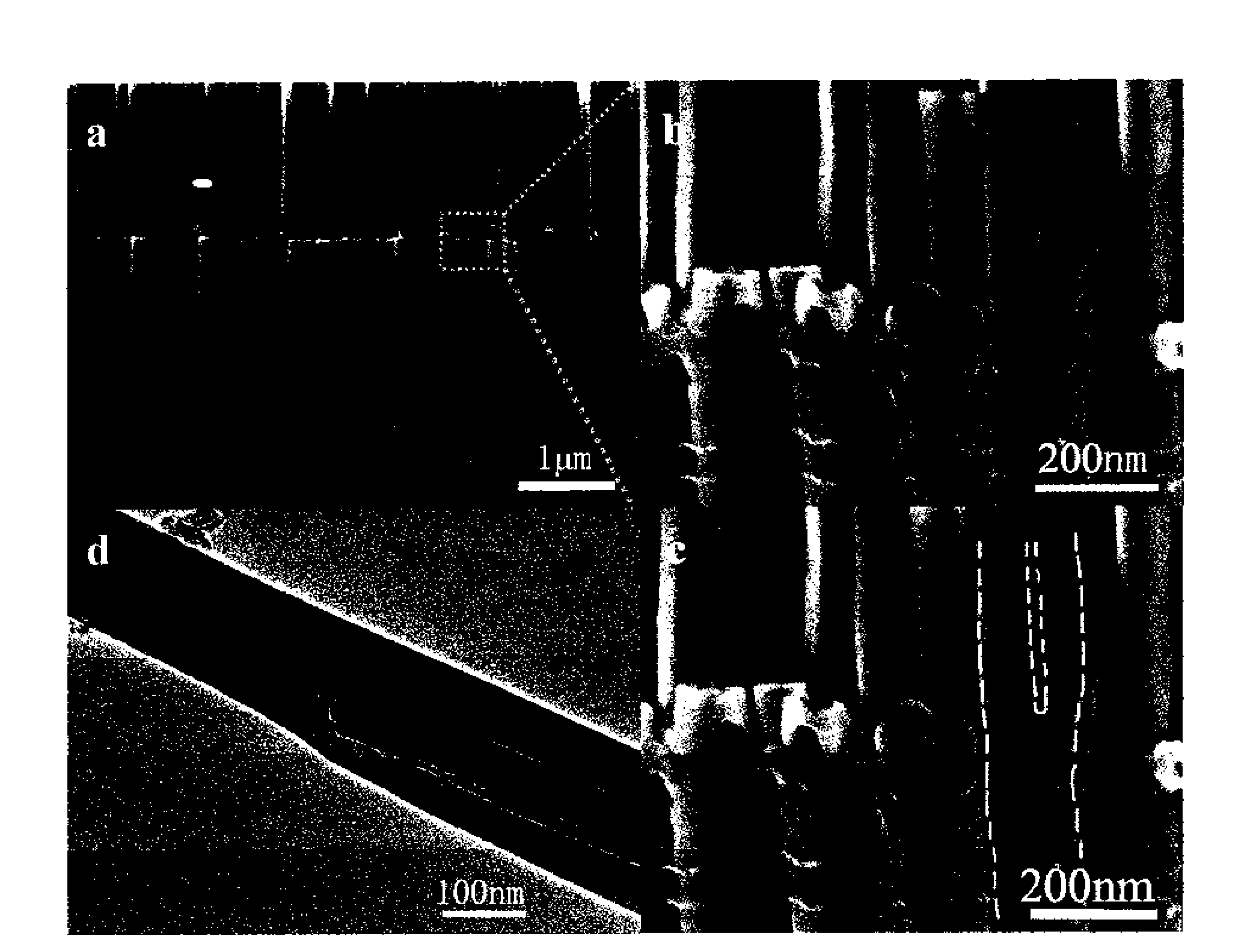

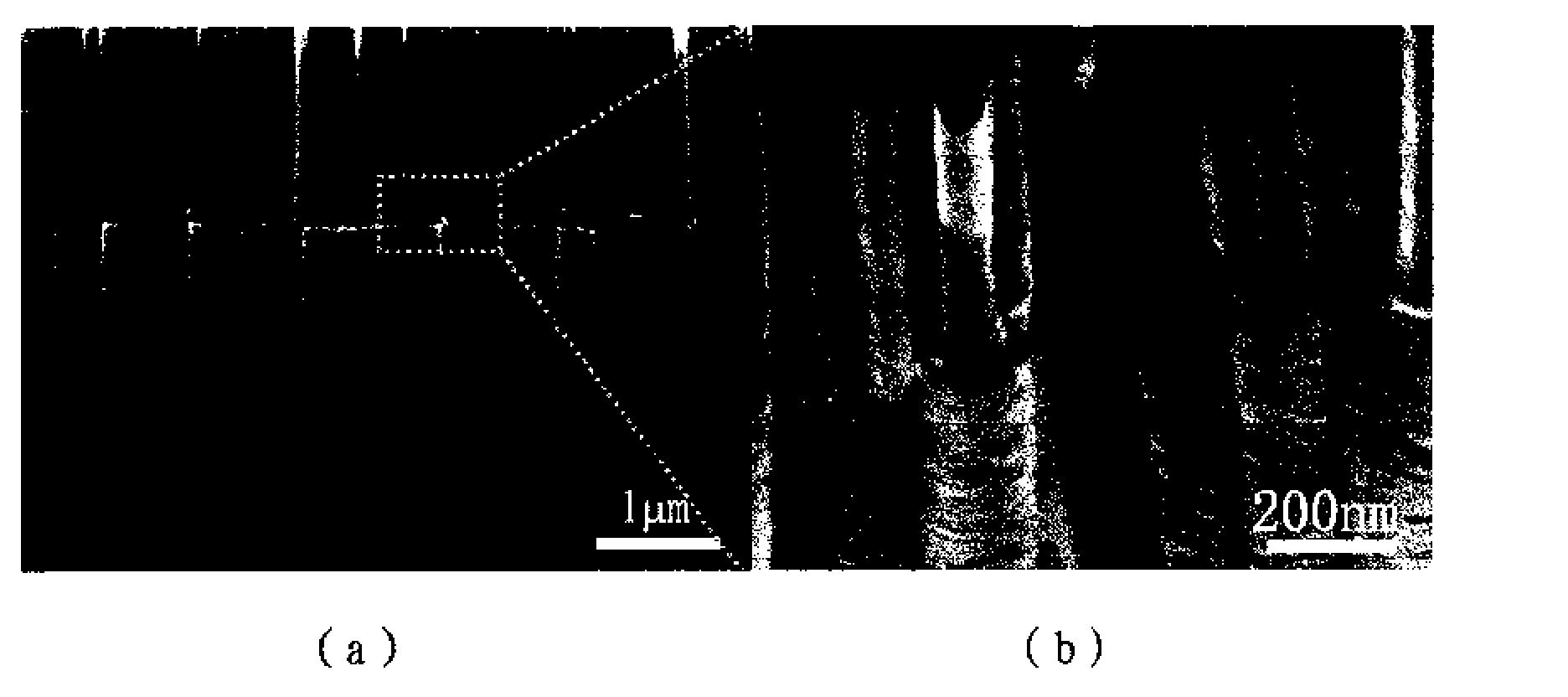

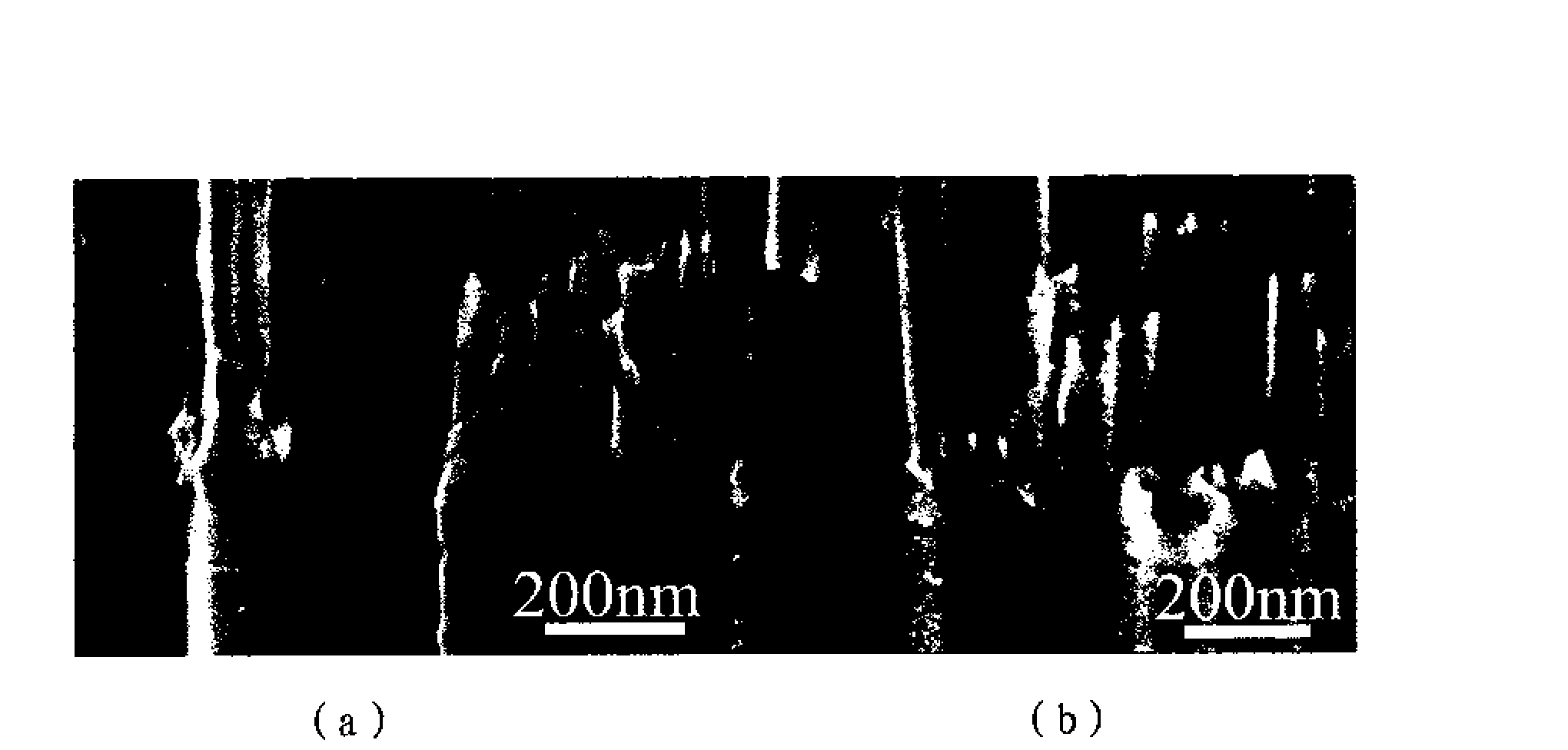

Embodiment 1

[0017] The specific steps of preparation are as follows: step 1, prepare the competent electrolyte according to the molar ratio of ammonium fluoride, ethylene glycol and water at a ratio of 0.05:17.7:0.015; Proportional preparation of the branch tube electrolyte; wherein, the water is deionized water, and the purity of the metal titanium sheet is 96%. Step 2, put the metal titanium sheet in a mixed solution of ethanol and acetone with a molar ratio of 1:1 and ultrasonically clean it for 30 minutes, then wash it with water and dry it in the air. After that, place one side of the metal titanium sheet in the main electrolyte as the anode , anodized at a DC voltage of 55V and a temperature of 0°C for 6h, and then cleaned once with ethylene glycol. Next, the anodized side was placed in the branch tube electrolyte as an anode, and anodized at a DC voltage of 30V and a temperature of 0°C for 60 minutes; wherein, the cathode during anodization was a graphite sheet. made approximately...

Embodiment 2

[0019] The specific steps of preparation are as follows: step 1, prepare the competent electrolyte according to the molar ratio of ammonium fluoride, ethylene glycol and water at a ratio of 0.08:17.7:0.018; The branch tube electrolyte is prepared in proportion; wherein, the water is distilled water, and the purity of the metal titanium sheet is 97%. Step 2, put the metal titanium sheet in a mixed solution of ethanol and acetone with a molar ratio of 1:1 and ultrasonically clean it for 35 minutes, then wash it with water and dry it in the air. After that, place one side of the metal titanium sheet in the main electrolyte as the anode , anodized at a DC voltage of 58V and a temperature of 9°C for 4.5h, and then cleaned twice with ethylene glycol. Next, the anodized side was placed in the branch tube electrolyte as an anode, and anodized at a DC voltage of 50V and a temperature of 9°C for 53 minutes; wherein, the cathode during anodization was a metal platinum sheet. made as i...

Embodiment 3

[0021]The specific steps of preparation are as follows: step 1, the main electrolyte is prepared according to the molar ratio of ammonium fluoride, ethylene glycol and water at a ratio of 0.1:17.7:0.02, and the molar ratio of hydrofluoric acid and ethylene glycol is 0.2:17.7 Proportional preparation of the branch tube electrolyte; wherein, the water is deionized water, and the purity of the metal titanium sheet is 98%. Step 2, place the metal titanium sheet in a mixed solution of ethanol and acetone with a molar ratio of 1:1 and ultrasonically clean it for 40 minutes, then wash it with water and dry it in the air. After that, place one side of the metal titanium sheet in the main electrolyte as the anode , anodized at a DC voltage of 60V and a temperature of 18°C for 3 hours, and then cleaned with ethylene glycol for 3 times. Next, the anodized side was placed in the branch tube electrolyte as an anode, and anodized at a DC voltage of 80V and a temperature of 18°C for 45 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com