On-water garbage collection ship

A technology for clearing water surface garbage and ships, applied in the field of engineering ships, can solve the problems of low work efficiency, heavy weight, limited cabin volume and load capacity, etc., and achieve the effects of improving efficiency, saving energy, and reducing the number of cleaning times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

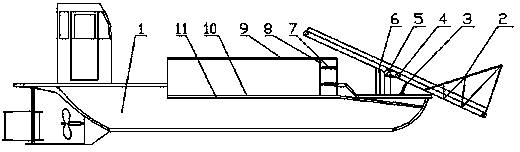

[0016] The implementation structure of the present invention will be described below in conjunction with the accompanying drawings.

[0017] The water surface garbage cleaning ship includes a hull 1, a conveying device and a storage box. The conveying device is installed at the front end of the hull 1. The conveying device includes a transmission frame 2, a support frame 6, a support cylinder 3, a conveyor belt 13, a roller 4 and a frequency conversion motor 5. , the transmission frame 2 is connected on the hull 1 through the support frame 6 and the support cylinder 3, the drum 4 is fixed on the transmission frame 2, the conveyor belt 13 is sleeved on the drum 4, and the frequency conversion motor 5 is connected with the drum 4.

[0018] The storage box is placed in the middle of the hull 1, and the storage box includes a box body 12, a compression cylinder 7, a compression plate 8, an upper sealing plate 9 and a bottom plate 10. One end of the compression cylinder 7 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com