Self-rotation type bag type dust collector

A bag filter and filter bag technology, applied in chemical instruments and methods, dispersed particle filtration, combined devices, etc., can solve the problems of ineffective utilization, short service life of filter bags, and low dust collection efficiency, and achieve Avoid uneven dust accumulation, good sealing and good blowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

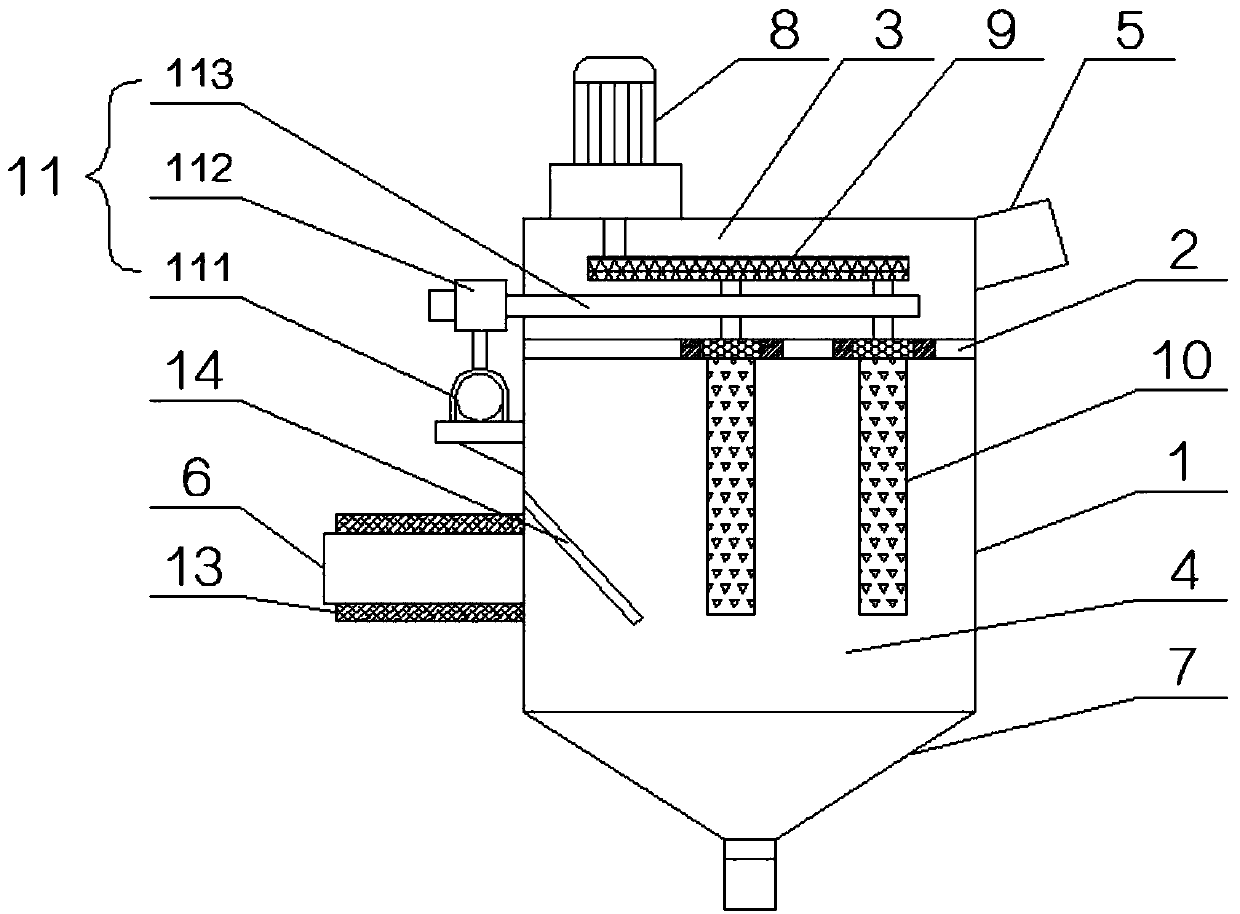

[0028] Such as Figure 1-3 As shown, a self-transformed bag filter includes a box 1 and a partition 2 arranged in the box 1, and the partition 2 separates the inside of the box 1 into a clean air chamber 3 and a dust filter room. 4. The clean air chamber 3 is located above the dust filter chamber 4, the clean air chamber 3 is provided with an air outlet 5, the dust filter chamber 4 is provided with an air inlet 6, and the bottom of the dust filter chamber 4 is provided with The ash hopper 7 also includes a power mechanism 8, a transmission mechanism 9 and several self-rotating filter bag assemblies 10;

[0029] The power mechanism 8 is arranged on the clean air chamber 3 , the self-rotating filter bag assembly 10 is arranged on the partition 2 , and the power mechanism 8 is connected with the self-rotating filter bag assembly 10 through a transmission mechanism 9 .

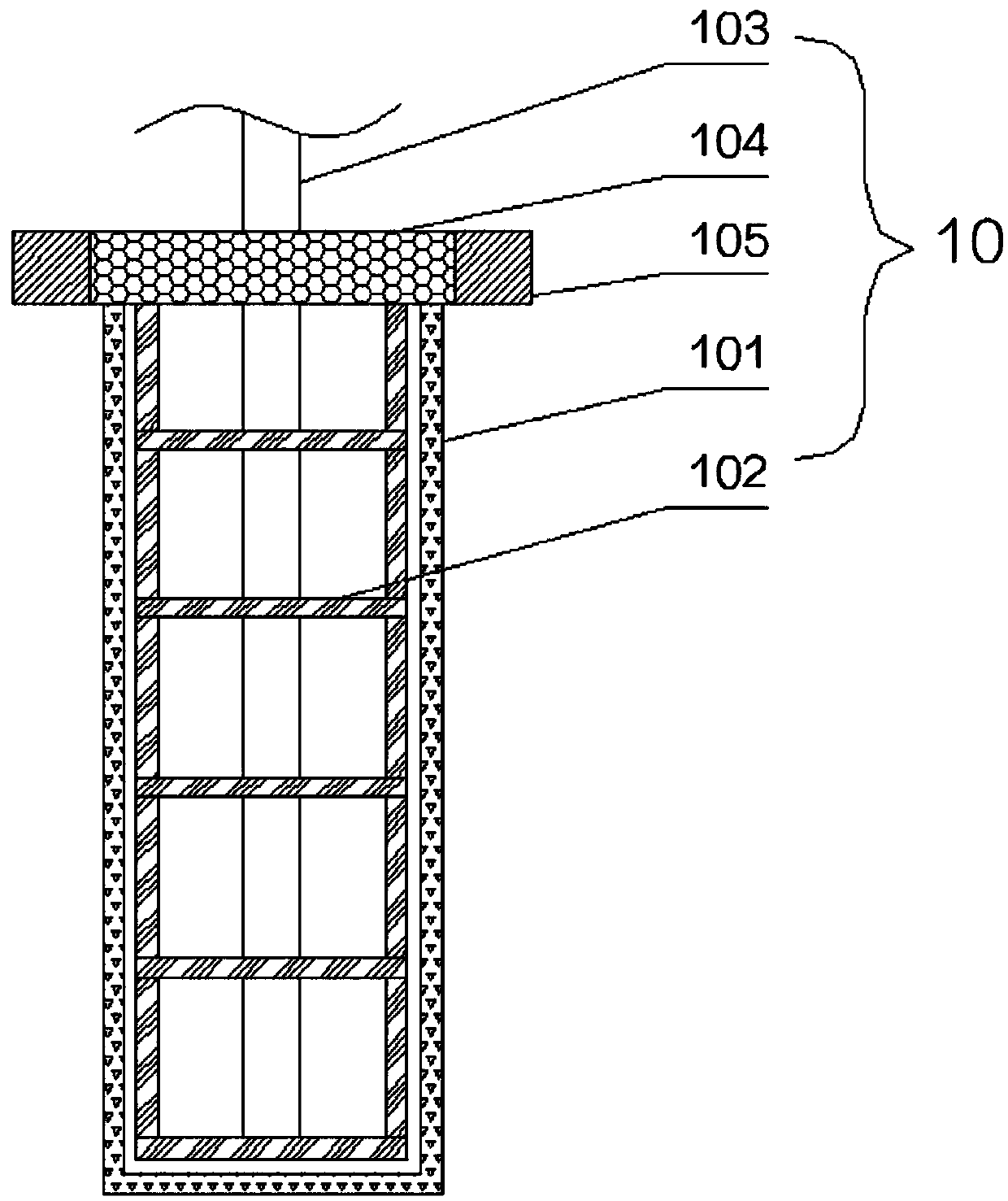

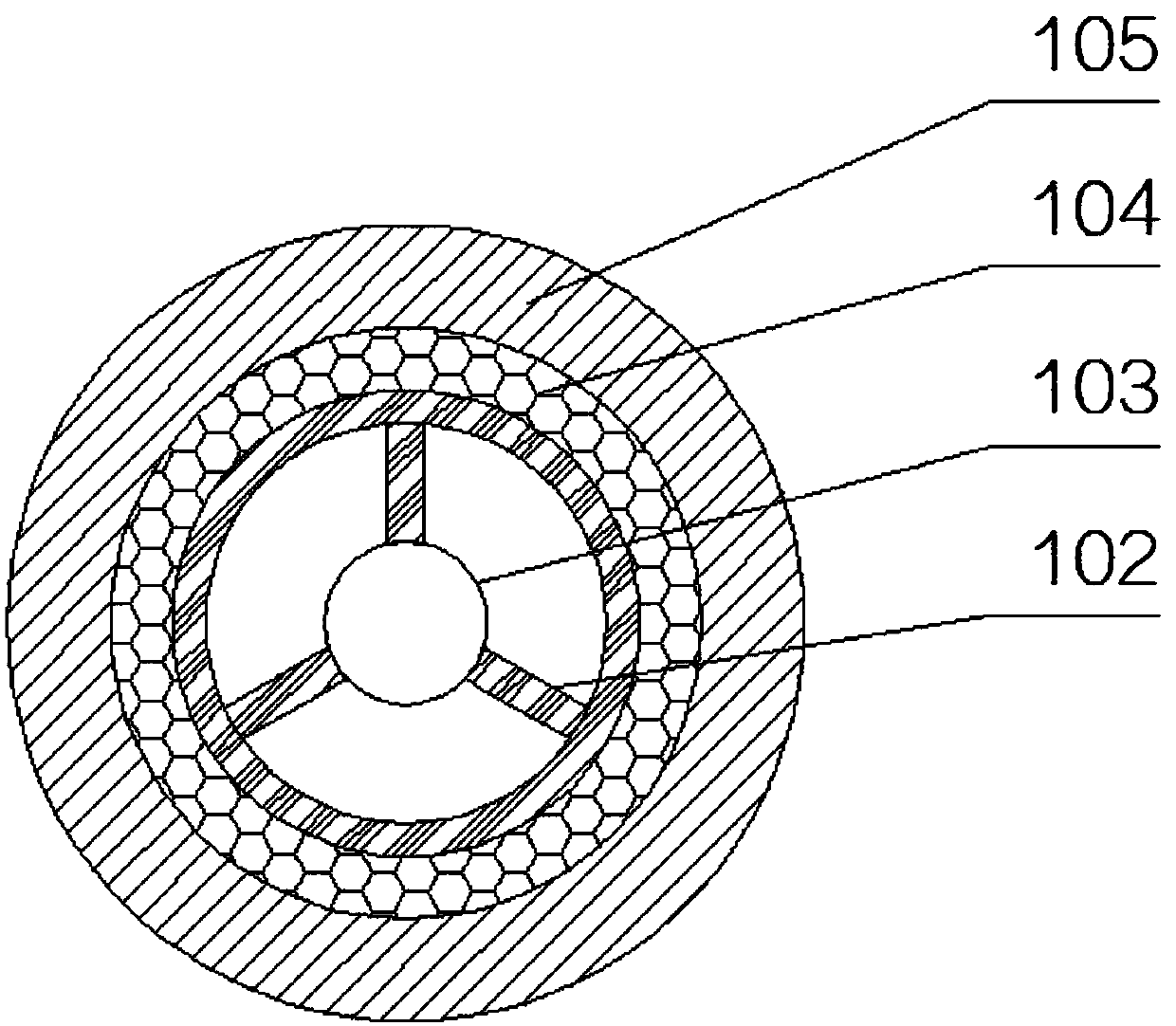

[0030] The self-rotating filter bag assembly 10 includes a filter bag 101, a filter bag skeleton 102, a rotati...

Embodiment 2

[0038] Such as figure 1 and 4 As shown, on the basis of Embodiment 1, a filter bag cleaning mechanism 11 is also included, which is used to shake off the excessive dust accumulated on the filter bag 101 into the ash hopper 7 .

[0039] The filter bag cleaning mechanism 11 includes an air bag 111, a pulse solenoid valve 112 and a blowing pipe 113. On the blowpipe 113, one end of the blowpipe 113 is connected with the air bag 111, and the other end of the blowpipe 113 stretches into the clean gas chamber 3, and the end of the blowpipe 113 stretched into the clean gas chamber 3 is provided with Several spray holes 12 are located above the filter bag 101 respectively.

[0040] One end of the blowing pipe 113 protruding into the clean air chamber 3 is U-shaped, and the rotating shafts 103 are respectively located in the middle of the U-shaped end of the blowing pipe 113 .

[0041] A self-transforming bag filter in this embodiment is provided with a filter bag dust removal mechan...

Embodiment 3

[0043] On the basis of Embodiment 2, the air inlet 6 is provided with a heating device 13 .

[0044] An inclined baffle 14 is also arranged inside the box 1 , and the baffle 14 is located at the air inlet 6 .

[0045] In the self-transforming bag filter of this embodiment, the air inlet 6 is provided with a heating device 13, which can heat the dusty gas entering the box body 1 and prevent the humid gas from adhering to the filter bag 101. , improve the filtering effect; the box 1 is also provided with an inclined baffle 14, the baffle 14 is located at the air inlet 6, which can effectively settle the dust with large particles and large specific gravity into the ash hopper 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com