Treatment method for oil field polymer-bearing wastewater

A treatment method and technology for sewage, which can be used in water/sewage multi-stage treatment, water/sludge/sewage treatment, mining wastewater treatment, etc. It can solve problems such as pollution and membrane flux attenuation, improve treatment efficiency, reduce cleaning number of times, the effect of extending the operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

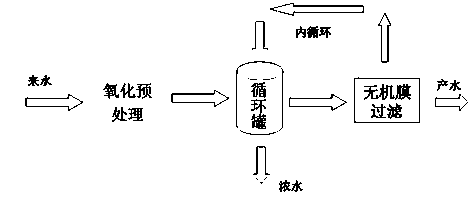

[0024] Such as figure 1 Shown, the oil field poly-containing sewage treatment method of the present invention may further comprise the steps:

[0025] Input the poly-containing sewage into the pretreatment device, using O 3 / H 2 o 2 Cooperative oxidation treatment. Concrete reaction condition is: pH value is under raw water alkaline condition, O 3 and H 2 o 2 The concentrations are 118mg / L and 15mg / L respectively, the oxidation time is 30min, and the reaction temperature is 30°C.

[0026] The oxidized sewage enters the inorganic membrane equipment for cross-flow filtration. The average pore size of the inorganic membrane is 20nm, the membrane surface flow velocity is 3m / s, the transmembrane pressure difference is 0.4MPa, the sewage temperature is 35°C, and the permeate is directly used In reinjection, the circulating fluid that has not penetrated the membrane is mixed with incoming water and then enters the inorganic membrane equipment for filtration again. The sewage i...

Embodiment 2

[0029] The method for treating oil field poly-containing sewage of the present invention comprises the following steps:

[0030] Step 1, input the sewage containing polymer into the pretreatment device, adopt O 3 / H 2 o 2 oxidation treatment. Concrete reaction condition is identical with embodiment 1. pH value under alkaline condition of raw water, O 3 and H 2 o 2 The concentrations are 118mg / L and 15mg / L respectively, the oxidation time is 30min, and the reaction temperature is 30°C.

[0031] Step 2, the oxidized sewage enters the inorganic membrane equipment for cross-flow filtration. The average pore size of the inorganic membrane is 20nm, the membrane surface flow velocity is 5m / s, the transmembrane pressure difference is 0.4MPa, and the sewage temperature is 10, 30, 50 , 70, 90, 95 ℃, the permeate is directly used for reinjection, the circulating fluid that has not permeated the membrane is mixed with the incoming water, and then enters the inorganic membrane equip...

Embodiment 3

[0035] Such as figure 1 Shown, the oil field poly-containing sewage treatment method of the present invention may further comprise the steps:

[0036] Step 1, input the poly-containing sewage into the pretreatment device, and use Fenton reagent for oxidation treatment. The specific reaction conditions are: Fe in Fenton's reagent 2+ and H 2 o 2 The concentrations are 100mg / L and 15mg / L respectively, the pH value of the system is 4, the reaction temperature is 40°C, and the reaction time is 60min.

[0037] Step 2. The oxidized sewage enters the inorganic membrane equipment for cross-flow filtration. The average pore size of the inorganic membrane is 200nm, the membrane surface flow velocity is 3m / s, the transmembrane pressure difference is 0.4MPa, and the sewage temperature is 50°C. The liquid is directly used for reinjection. The circulating liquid that has not penetrated the membrane is mixed with the incoming water and then enters the inorganic membrane equipment for filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com