Reaction vessel for luminescence tester and cleaning and separating mechanism thereof

A separation mechanism and reaction cup technology, applied in the field of chemiluminescence immunoassay system, can solve the problems affecting the reliability and repeatability of the results, absorbing magnetic beads, affecting the measurement speed, etc., to speed up the test speed, clean thoroughly, reduce The effect of the number of washes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

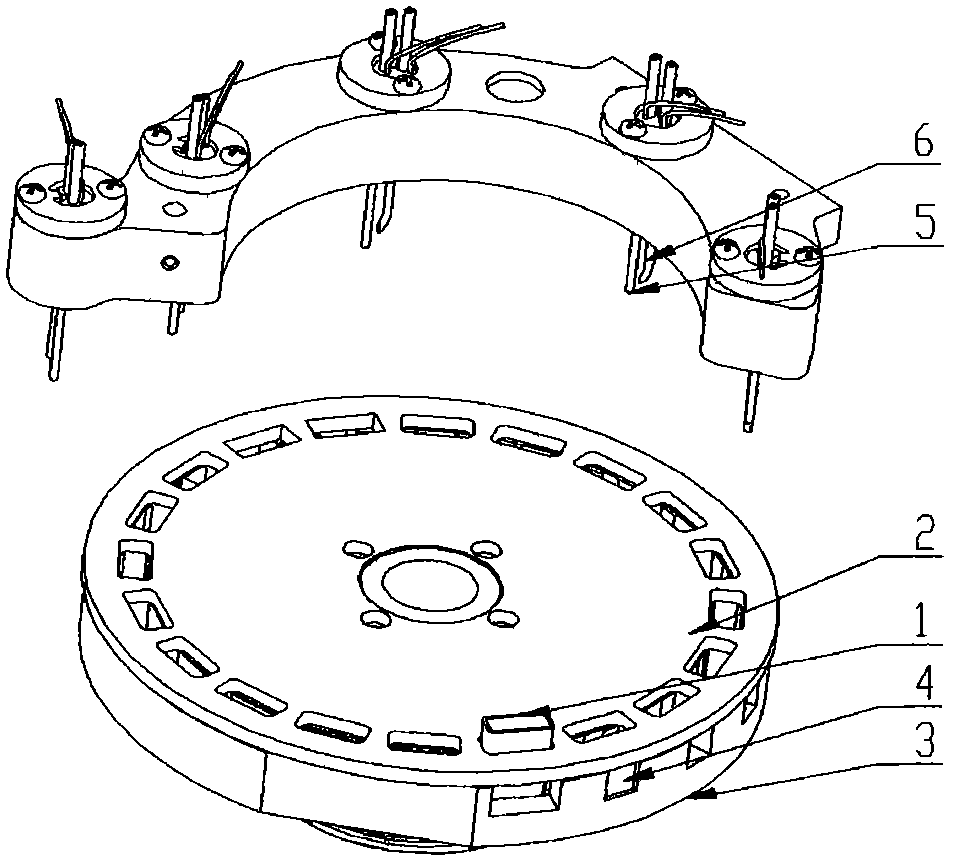

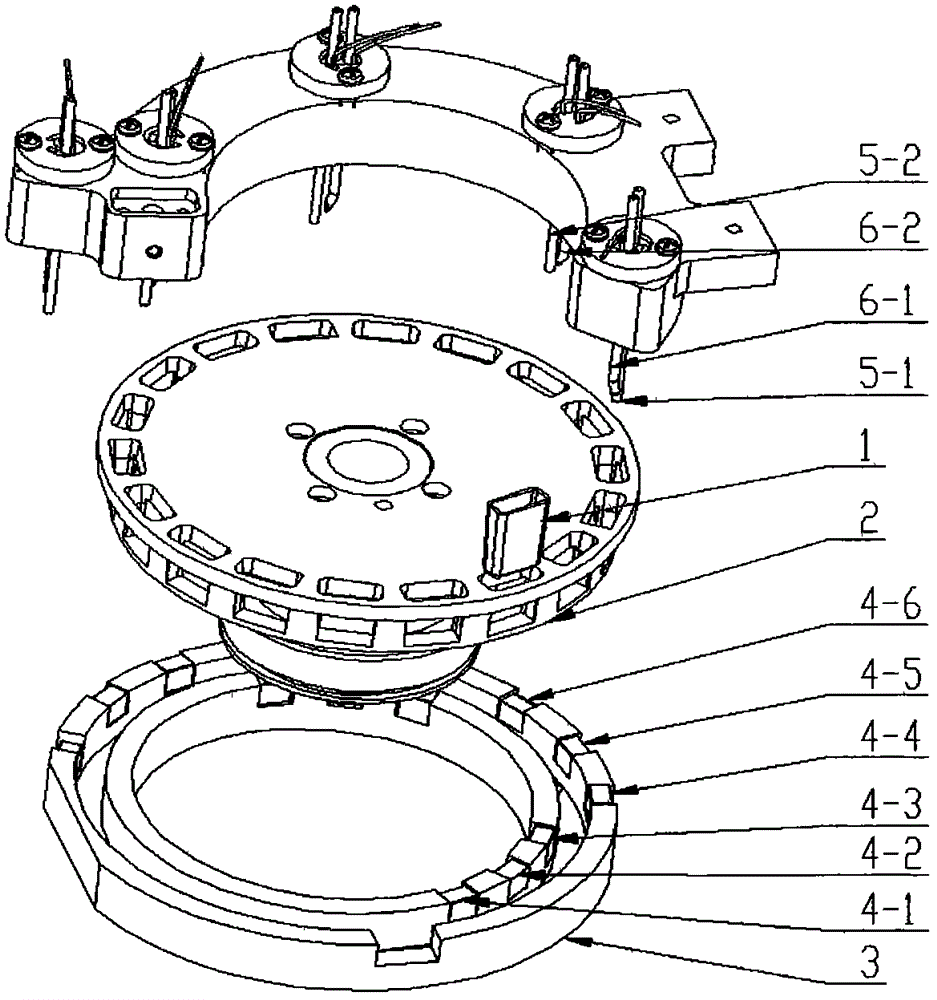

[0010] like image 3 A special example of a cuvette for a luminescence measuring instrument and its corresponding cleaning and separation mechanism is shown. When the cuvette containing the reactant is placed on a specific position of the cleaning turntable, the turntable rotates according to a certain period of time, and sequentially passes through the separation mechanism. The magnets 4-1, 4-2, and 4-3 reach the bottom of the needle drawing 5-1 and the washing needle 6-1. The drawing needle first draws away the liquid in the cup, and then the washing needle injects the lotion into the cup, and then The turntable continues to rotate according to a certain period of time, passing through the separation magnets 4-4, 4-5, 4-6 in turn to the bottom of the needle drawing 5-2 and washing needle 6-2. Then wash the needle to inject the lotion into the cup. Because the magnets 4-1, 4-2, and 4-3 are on the inside of the cup, and 4-4, 4-5, and 4-6 are on the outside of the cup, therefo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com