Porous ceramic membrane material for photo-thermal sea water desalination and preparation method and application

A porous ceramic membrane and porous ceramic technology are applied in the field of porous materials and preparation for photothermal seawater desalination, which can solve the problems of pollution of the environment by the preparation process, short service life of membranes, poor solvent resistance, etc. The effect of high preparation efficiency and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The first step: powder preparation

[0040] Obtain Ti powder, Al powder, TiO 2 Powder, B 2 o 3 Powder, B 4 C powder, TiH 2 Powder and other mixed powders are used as raw materials, and the molar ratio is: 4:11:3:3:3:0.2; put the powder into a ball mill and mix for 4 hours;

[0041] Step Two: Preparation for Plasma Heating

[0042] Lay a layer of mixed powder on the plasma workbench, with a thickness of 10um and a green body with a diameter of Φ100mm;

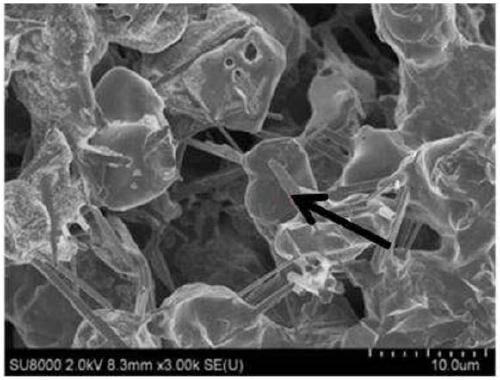

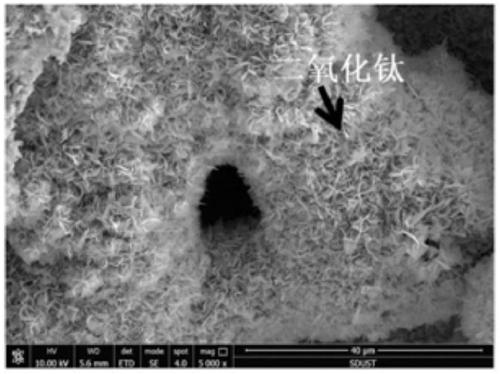

[0043] Step 3: Synthesis of Porous Ceramic Membrane Foam Board

[0044] Turn on the normal pressure DC plasma beam power supply, the plasma beam current is 100A, the voltage is 50V, and the scanning speed is 10mm / s, and the powder green body is scanned and heated by the plasma beam current. Under the action of plasma heat, the mixed powder green body reacts: Ti+B 4 C+TiH 2 +Al+TiO 2 +B 2 o 3 →TiAl+TiB+TiB 2 +Ti 3 B 4 +TiC+TiB 2 +Al 2 o 3 +H 2 , the porous ceramic membrane foam plate is obtained after the...

Embodiment 2

[0052] Embodiment two removes TiH in the first step powder preparation 2 The molar ratio is changed from 0.2 to 1.0, and in the third step of the synthesis of the porous ceramic membrane foam board, the plasma beam current is changed to 50A, and the scanning speed is 20mm / s. Except for the parameter changes in the above two steps, all other processes and parameters are the same as in the first embodiment.

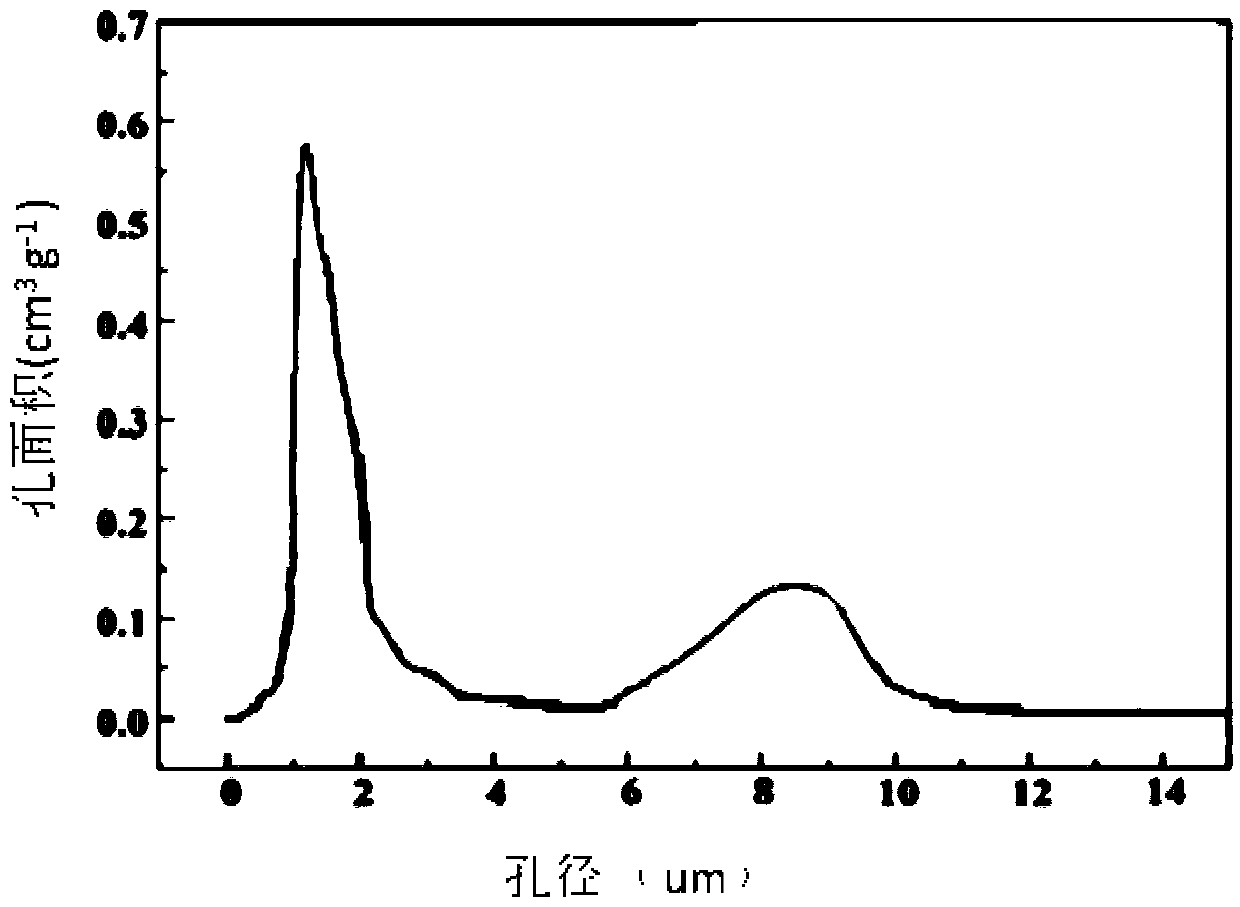

[0053] A porous ceramic membrane foam plate with a pore diameter of 2.0-4 μm and a porosity of 75% is finally obtained, which becomes a porous ceramic heterogeneous structure membrane after hydrothermal synthesis and calcination.

Embodiment 3

[0055] In addition to the TiH in the first step of powder preparation 2 The molar ratio of the compound was changed from 0.2 to 0.6, and in the third step of the synthesis of the porous ceramic membrane foam plate, the plasma beam current was changed to 70A, and the scanning speed was 15mm / s. Except for the parameter changes in the above two steps, all other processes and parameters are the same as in the first embodiment.

[0056] A porous membrane with a pore diameter of 1.0-3 μm and a porosity of 55% is finally obtained, which becomes a porous ceramic heterostructure membrane after hydrothermal synthesis and calcination.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com