Rectangular spoiler metal honeycomb carrier

A metal honeycomb carrier and rectangular sheet technology, applied in gas treatment, separation methods, machines/engines, etc., can solve the problems of inhomogeneous flue gas catalysis, weakened catalytic effect, uneven gas flow rate, etc., to ensure catalytic purification effect, improve Catalytic purification effect, flue gas distribution and uniform flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

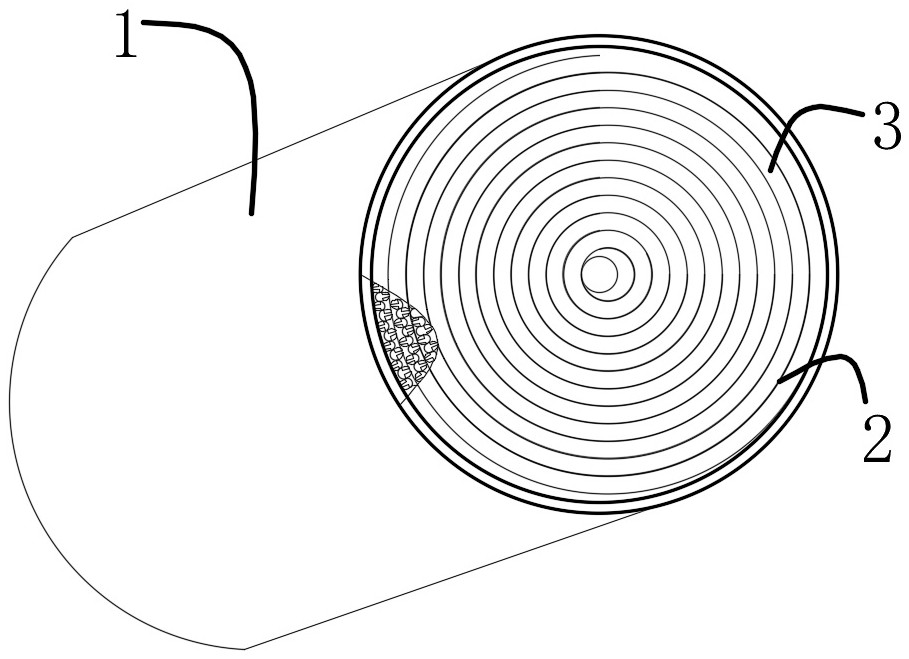

[0022] figure 1 A three-dimensional structure diagram of the rectangular-disturbance metal honeycomb carrier is shown, and several airflow channels 4 arranged in parallel are formed in the metal honeycomb carrier. Before the metal honeycomb carrier is placed into the engine exhaust pipe, it needs to be soaked in the liquid containing the catalyst, and after air drying, the catalyst is adhered to the inner wall of the air flow channel 4, and the smoke generated by the internal combustion engine enters the air flow channel 4 After being inside, it will be catalytically purified after contacting with the catalyst.

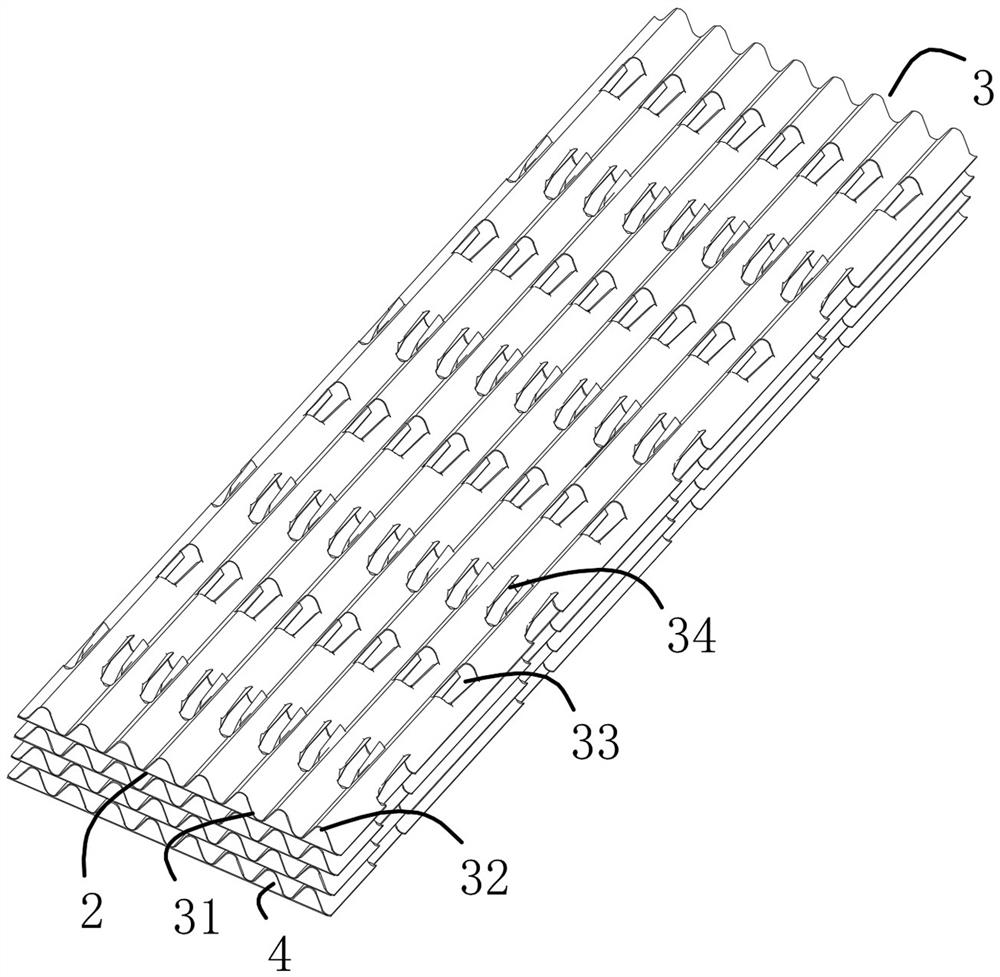

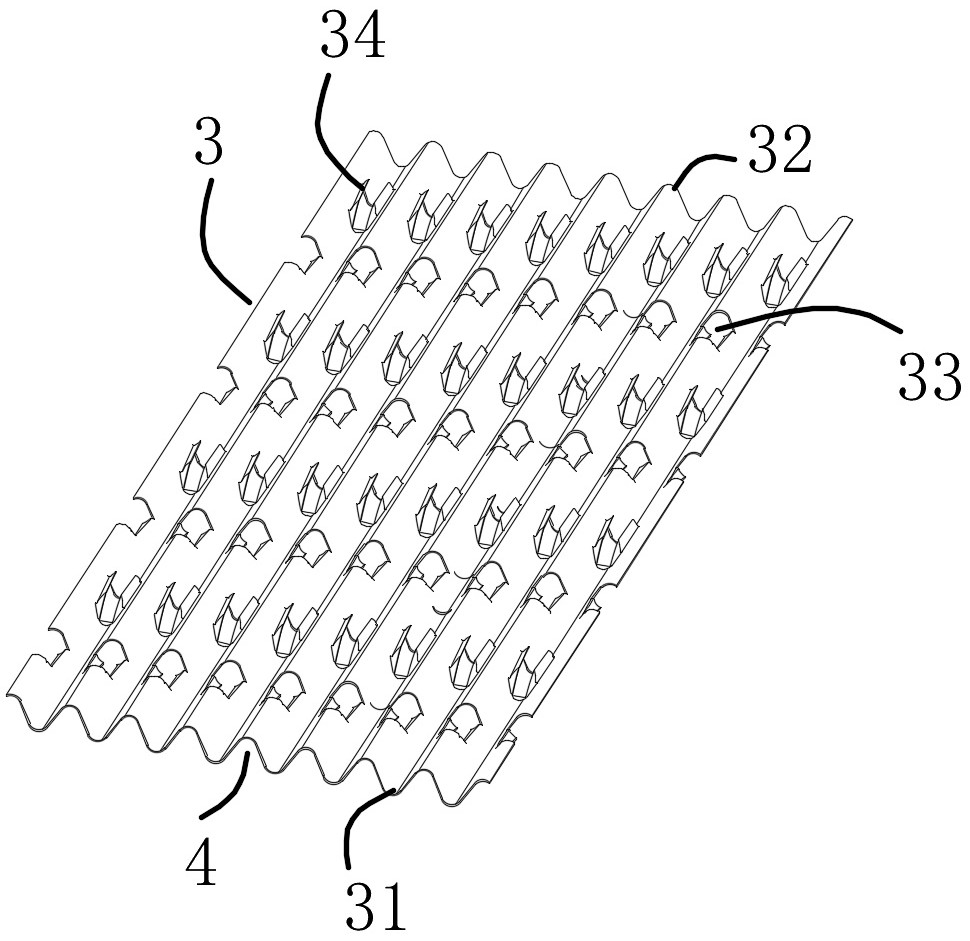

[0023] See figure 2 , 3 , 4, and 5, the foil strip 3 is a metal sheet, which itself is folded into a curved plate shape. Thereby, a number of crests 32 and troughs 31 arranged side by side are formed on it, and the crests 32 and troughs 31 are alternately arranged and connected together, and the cross-section of the formed foil strip 3 is sinusoidal. When prepari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com