Air-liquid cooling integrated high-efficiency heat exchange tube

A heat exchange tube and integrated technology, which is applied in the field of high-efficiency air-liquid cooling integrated heat exchange tubes, can solve problems such as difficulty in meeting the needs of rapid cooling of high-viscosity fluids, and achieve improved air-cooled heat transfer effects, improved air-cooled effects, and improved cooling effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

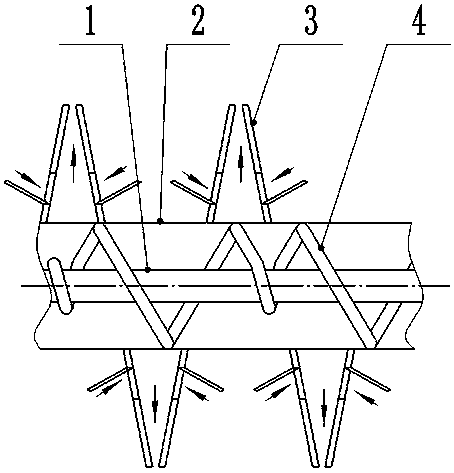

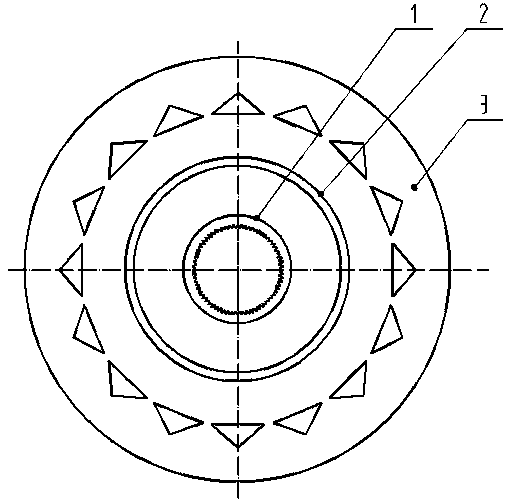

[0019] Such as figure 1 and 2 , an air-liquid-cooled integrated high-efficiency heat exchange tube, comprising an outer sleeve 2 and a core tube 1 coaxially arranged in the outer sleeve 2, thereby forming a high-temperature tube located inside the outer sleeve 2 and outside the core tube 1 and having a circular cross-sectional shape Fluid area: the core tube 1 is used to transport low-temperature cooling medium, and the high-temperature fluid area is used to transport high-temperature and high-viscosity fluid to be cooled.

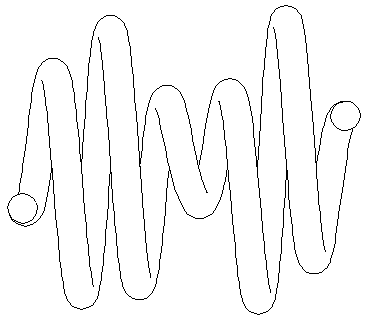

[0020] The outer surface of the core tube 1 is smooth, and the inner surface is provided with ribs. The core tube 1 is also equipped with a helical variable diameter spring 4. The diameter of the spring wire is between 0.2 and 10 mm, and the cross section of the spring wire is a multi-section arc. Composition, the spring wire cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com