Integrated hot blast stove

A hot blast stove and integrated technology, which is applied in the field of integrated hot blast stoves, can solve problems such as increased impact probability, low energy utilization rate, and increased air density, and achieve the effects of reducing heat waste, slowing down heat loss, and improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will now be further described with reference to the accompanying drawings and specific embodiments.

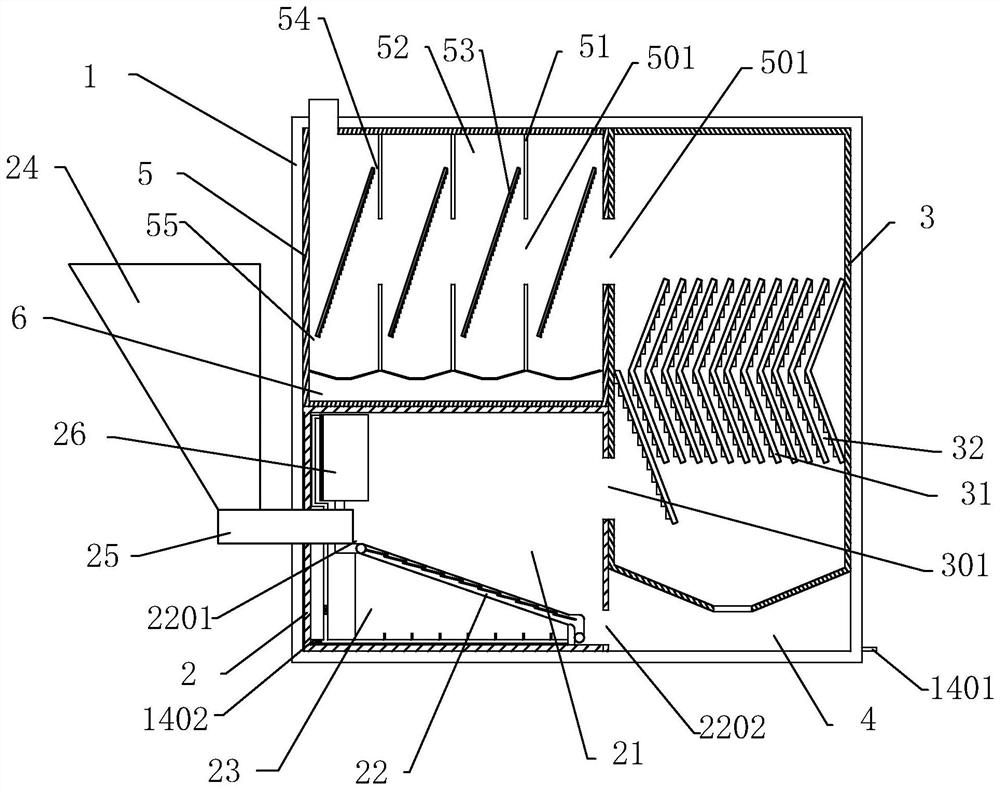

[0027] refer to Figure 1 to Figure 8 , This embodiment provides an integrated hot blast stove, including a casing 1, and the casing 1 is provided with a combustion chamber 2, a primary ash chamber 3 and a secondary ash chamber 5.

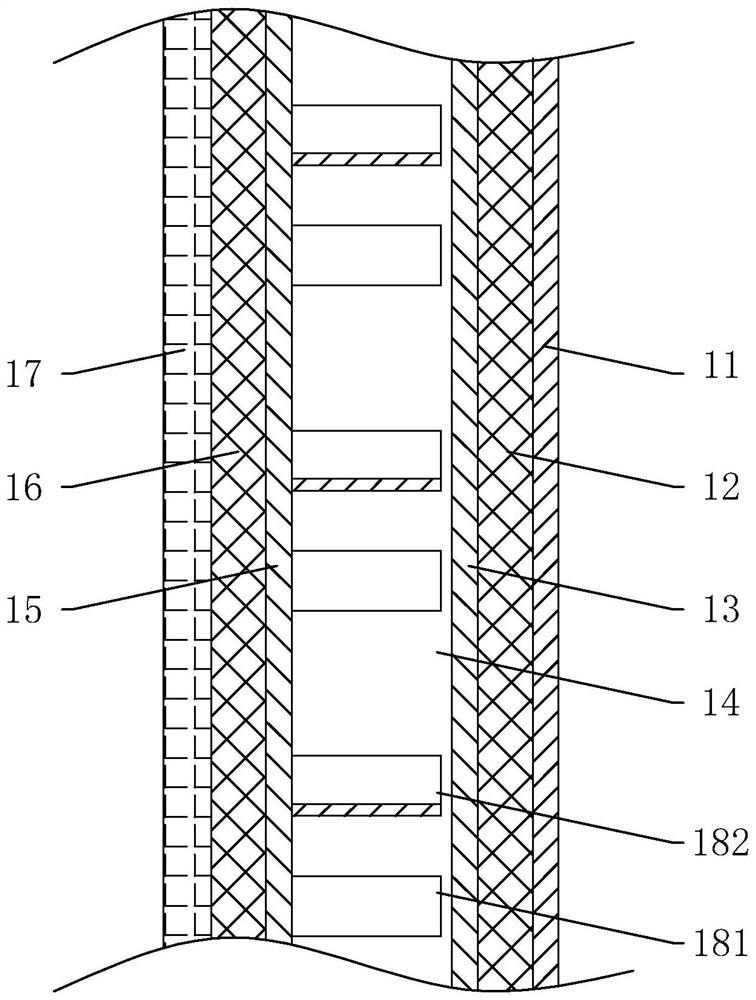

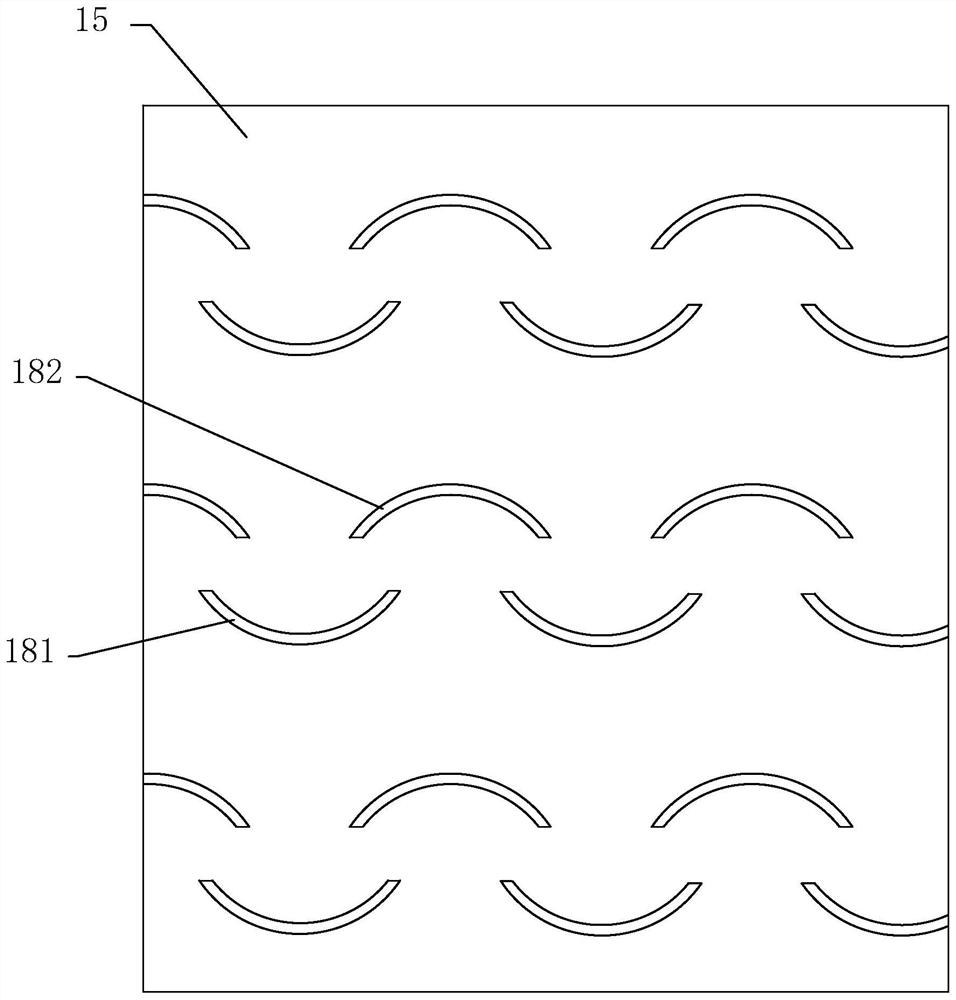

[0028] The casing 1 includes a decorative panel 11, an outer thermal insulation layer 12, an outer panel 13, a cold air passage 14, a middle panel 15, an inner thermal insulation layer 16 and an inner panel 17 in sequence from the outside to the inside, and the cold air passage 14 is provided with an air inlet 1401 and an air outlet 1402, the air inlet 1401 is connected to an external fan, and the cold air passage 14 is provided with a plurality of sets of heat dissipation components at intervals from the air inlet 1401 to the air outlet 1402 on the middle plate 15. The first heat dissipation plate 181 and the second h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com