Preparation method of high-strength alkali-resistant brick

An alkali-resistant brick and high-strength technology, applied in clay products, applications, household appliances, etc., can solve problems such as damage, poor alkali resistance, and easy damage to the brick body, so as to improve alkali resistance, ensure density, and ensure safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

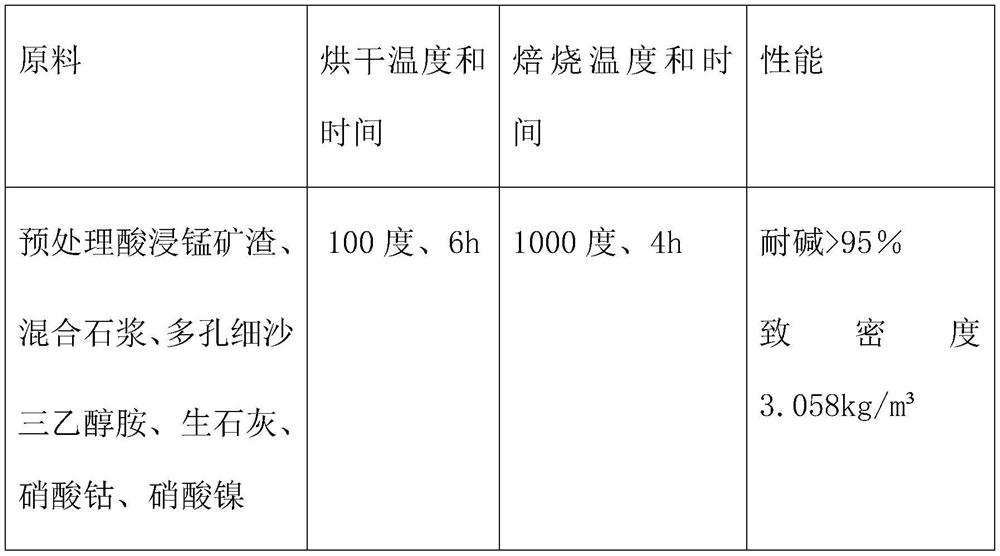

Embodiment 1

[0030] A method for preparing high-strength alkali-resistant bricks, comprising a mixing stage, a brick forming stage, a drying stage, a preheating stage, a roasting stage, a heat preservation stage and a cooling stage, and the specific steps are as follows:

[0031] S1: In the mixing stage, the raw materials are fully mixed and stirred according to the predetermined ratio, and humidified after stirring;

[0032] S2: In the adobe forming stage, the stirred and humidified raw materials are molded with a mold to form a block of cuboids to obtain adobe;

[0033] S3: In the drying stage, the bricks are placed on the conveyor belt of the firing kiln, and the bricks are heated by the hot air system of the firing kiln;

[0034] S4: In the preheating stage, the firing exhaust gas from the firing kiln in other firing stages is introduced, and the bricks are preheated in conjunction with the heating system in the firing kiln in the preheating stage. The upper limit of the preheating tem...

Embodiment 2

[0045] A method for preparing high-strength alkali-resistant bricks, comprising a mixing stage, a brick forming stage, a drying stage, a preheating stage, a roasting stage, a heat preservation stage and a cooling stage, and the specific steps are as follows:

[0046] S1: In the mixing stage, the raw materials are fully mixed and stirred according to the predetermined ratio, and humidified after stirring;

[0047] S2: In the adobe forming stage, the stirred and humidified raw materials are molded with a mold to form a block of cuboids to obtain adobe;

[0048] S3: In the drying stage, the bricks are placed on the conveyor belt of the firing kiln, and the bricks are heated by the hot air system of the firing kiln;

[0049] S4: In the preheating stage, the firing exhaust gas from the firing kiln in other firing stages is introduced, and the bricks are preheated in conjunction with the heating system in the firing kiln in the preheating stage. The upper limit of the preheating tem...

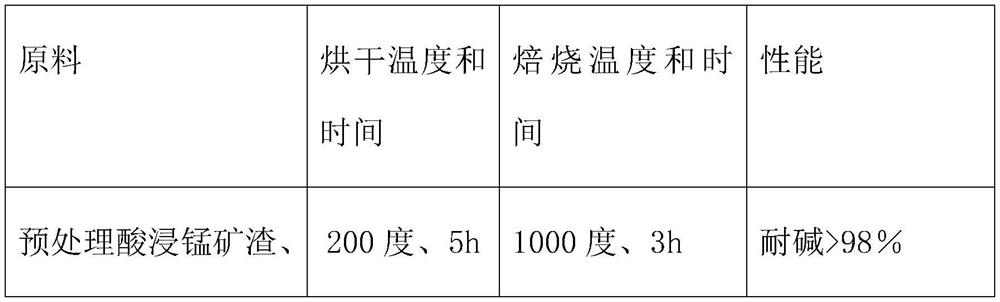

Embodiment 3

[0061] A method for preparing high-strength alkali-resistant bricks, comprising a mixing stage, a brick forming stage, a drying stage, a preheating stage, a roasting stage, a heat preservation stage and a cooling stage, and the specific steps are as follows:

[0062] S1: In the mixing stage, the raw materials are fully mixed and stirred according to the predetermined ratio, and humidified after stirring;

[0063] S2: In the adobe forming stage, the stirred and humidified raw materials are molded with a mold to form a block of cuboids to obtain adobe;

[0064] S3: In the drying stage, the bricks are placed on the conveyor belt of the firing kiln, and the bricks are heated by the hot air system of the firing kiln;

[0065] S4: In the preheating stage, the exhaust gas from the firing kiln in other firing stages is introduced, and the brick is preheated in conjunction with the heating system in the firing kiln in the preheating stage. The upper limit of the preheating temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com