Preparation method of lithium nickel manganese cobalt positive electrode material, lithium ion battery positive electrode material and lithium ion battery

A technology of nickel cobalt lithium manganate and lithium ion batteries, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem that the electrochemical performance of products cannot be guaranteed, the uniformity of precursor lithium mixing is poor, and the bulk density of powder materials can be solved. Low problems such as excellent cycle stability, improved material stability, and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] In the first aspect, this embodiment provides a method for preparing a nickel-cobalt lithium manganese oxide positive electrode material, comprising the following steps:

[0041](a) preparing an aqueous solution of a ternary material precursor with a weight concentration of 45% to 60%;

[0042] (b) preparing an aqueous solution of a lithium source compound with a weight concentration of 20% to 30%;

[0043] (c) pumping the aqueous solution of the ternary material precursor and the aqueous solution of the lithium source compound into the mixer respectively, mixing and stirring evenly to obtain a suspension;

[0044] (d) spray drying the suspension to obtain a mixed lithium powder;

[0045] (e) Sintering the lithium complex mixed powder to obtain a positive electrode material of nickel cobalt lithium manganese oxide.

[0046] In view of the fact that in the preparation process of the existing nickel-cobalt lithium manganese oxide positive electrode material, there are f...

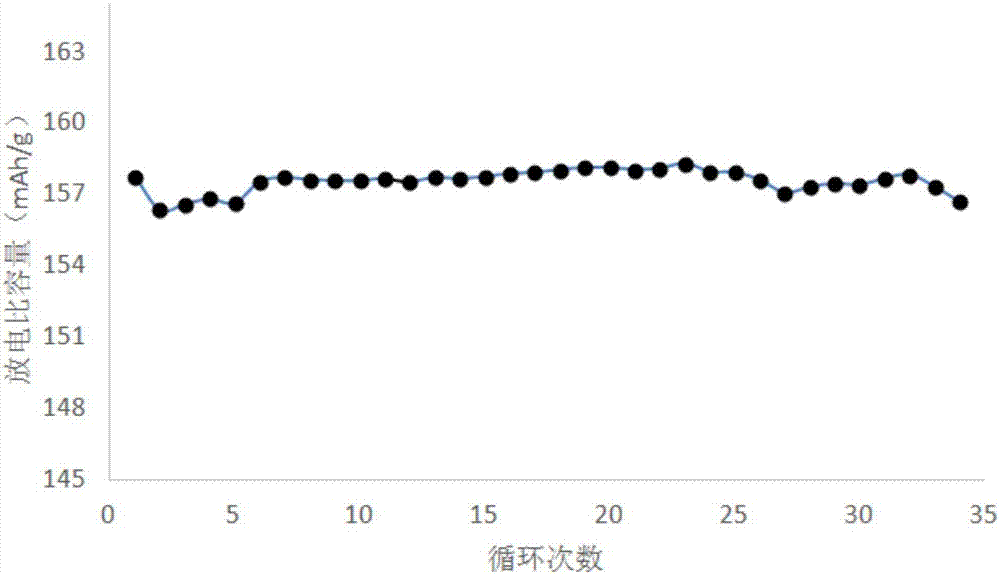

Embodiment 1

[0091] A preparation method of nickel-cobalt lithium manganese oxide cathode material, comprising the following steps:

[0092] (a) Preparation of ternary material precursor Ni with a weight concentration of 45% 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 aqueous solution;

[0093] (b) preparation weight concentration is the aqueous solution of lithium hydroxide monohydrate of 20%;

[0094] (c) The ternary material precursor Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 The aqueous solution of lithium hydroxide monohydrate and the aqueous solution of lithium hydroxide monohydrate are transported in the high-speed mixer respectively with pump, and the rotating speed of mixer is 2500rpm, and stirring time is 60min, and stirring temperature is normal temperature, mixes and stirs evenly, obtains suspension;

[0095] (d) Spray drying the suspension, the compressed air pressure of the spray dryer is 0.15MPa, and the temperature at the nozzle is 250°C to obtain a mixed lithium powder;

[0096] (e) Sinter the mi...

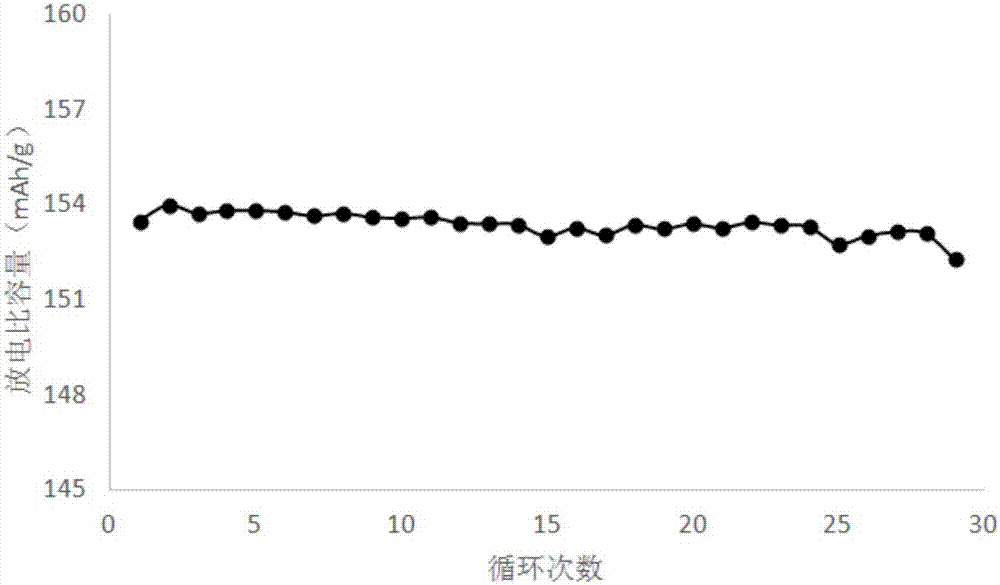

Embodiment 2

[0098] A preparation method of nickel-cobalt lithium manganese oxide cathode material, comprising the following steps:

[0099] (a) Preparation of ternary material precursor Ni with a weight concentration of 50% 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 The aqueous solution of the aqueous solution, and the aqueous solution is ultrasonically treated, the ultrasonic frequency is 30KHz, and the ultrasonic treatment time is 30min;

[0100] (b) preparing an aqueous solution of lithium hydroxide monohydrate with a weight concentration of 25%, and performing ultrasonic treatment on the aqueous solution, the ultrasonic frequency is 40KHz, and the ultrasonic treatment time is 30min;

[0101] Steps (c), (d), (e) are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com