Preparation method of cobalt-free positive electrode material

A positive electrode material and system technology, applied in the field of preparation of cobalt-free positive electrode materials, to achieve the effects of excellent phase change reversibility and structural stability, ease of dissolution, and large discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The invention provides a method for preparing a cobalt-free positive electrode material, comprising the following steps:

[0031] (1) Mix nickel sulfate and manganese sulfate salt solution according to Ni:Mn stoichiometric ratio 0.75:0.25, then add nano-alumina according to Al:Ni stoichiometric ratio 0.005:1, ultrasonic; in nitrogen atmosphere, mix the above solution into the reaction kettle, and then add a mixed alkali solution of NaOH and ammonia water to adjust the pH to 11.3, and the reaction temperature to 50°C. After the reaction, wash, filter, and dry.

[0032] (2) Lithium hydroxide (LiOH·H 2 O) Mix evenly with the powder obtained in step (1), calcine at a constant temperature of 910° C. for 12 hours in an oxygen atmosphere, and cool naturally to obtain a cobalt-free positive electrode material.

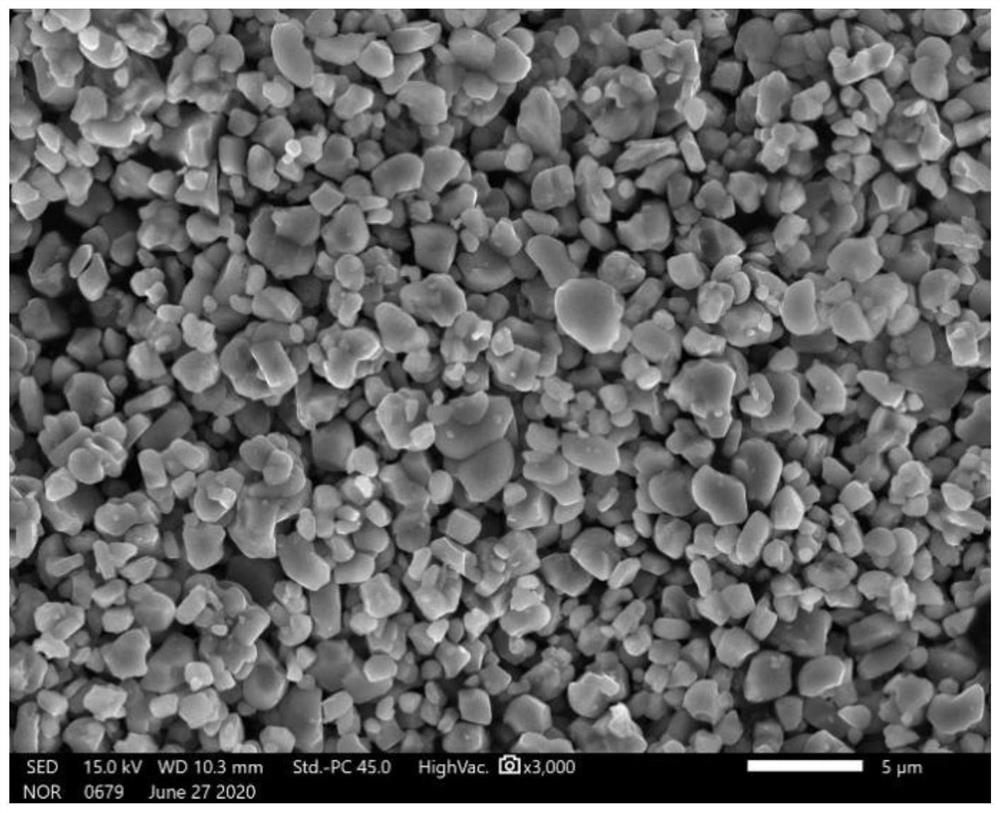

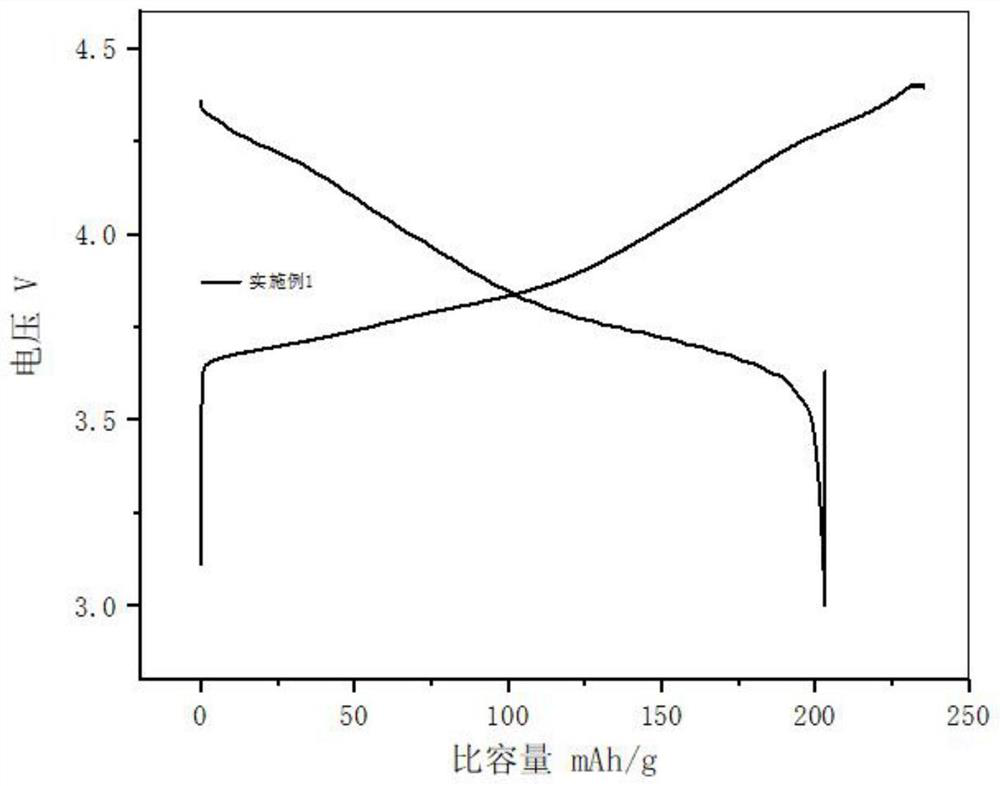

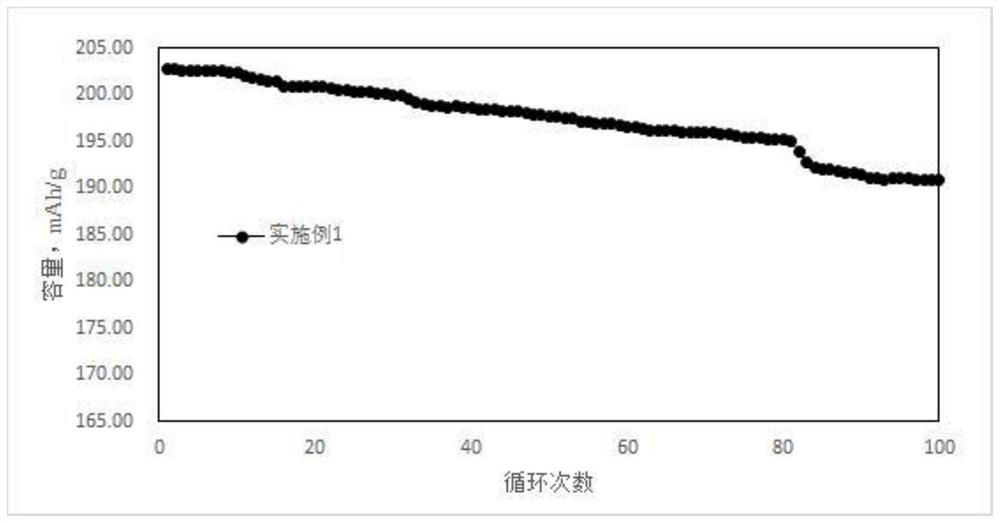

[0033] In conjunction with the accompanying drawings, the phase characterization and electrochemical performance of the cobalt-free positive electrode material prepare...

Embodiment 2

[0037] (1) Mix nickel nitrate and manganese nitrate salt solution by Ni:Mn stoichiometric ratio 0.60:0.40, then add nano-alumina and nano-magnesia by Al:Mg:Ni stoichiometric ratio 0.005:0.003:1, ultrasonic; In a nitrogen atmosphere, the above mixed solution was added to the reactor, and then a mixed alkali solution of KOH and ammonia was added to adjust the pH to 11.2, and the reaction temperature was 60°C. After the reaction, it was washed, filtered and dried.

[0038] (2) Lithium hydroxide (LiOH·H 2 O) Mix evenly with the powder obtained in step (1), calcinate at a constant temperature of 760° C. for 15 hours in an oxygen atmosphere, and cool naturally to obtain a cobalt-free positive electrode material.

[0039] The discharge specific capacity of the cobalt-free cathode material prepared in Example 2 is 183.5mAh / g, and the capacity retention rate remains at 92.33% after 100 cycles.

Embodiment 3

[0041] (1) Mix nickel chloride and manganese chloride salt solution by Ni:Mn stoichiometric ratio 0.70:0.30, then add nano-tungsten oxide by W:Ni stoichiometric ratio 0.008:1, ultrasonic; in nitrogen atmosphere, put The above-mentioned ion mixture is added to the reaction kettle, and then a mixed alkali solution of KOH and ammonia water is added to adjust the pH to 11.2, and the reaction temperature is 50°C. After the reaction is completed, it is washed, filtered, and dried.

[0042] (2) Lithium hydroxide (LiOH·H 2 O) Mix evenly with the powder obtained in step (1), calcinate at a constant temperature of 840° C. for 12 hours in an oxygen atmosphere, and cool naturally to obtain a cobalt-free positive electrode material.

[0043] The discharge specific capacity of the cobalt-free cathode material prepared in Example 3 is 194.3mAh / g, and the capacity retention rate remains at 94.28% after 100 cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com