Lead-carbon battery for motorcycle and preparation method thereof

A technology of lead-carbon batteries and motorcycles, which is applied in the direction of lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the problems of high discharge rate and poor charging conditions, achieve specific energy and cycle life, and improve charging performance and performance The effect of stabilizing prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

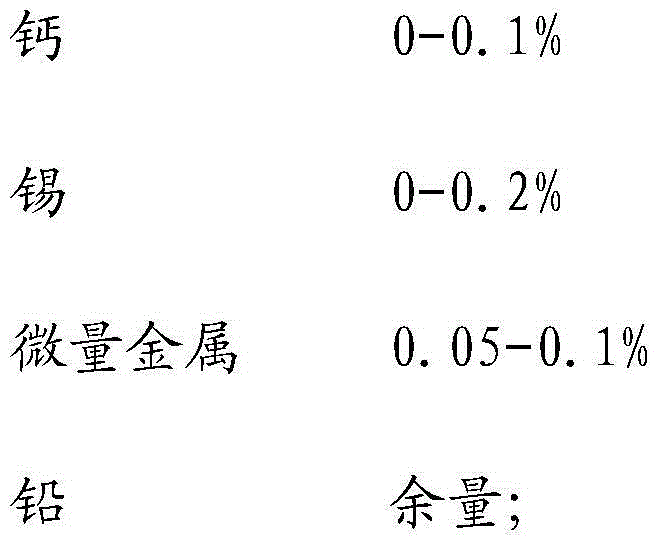

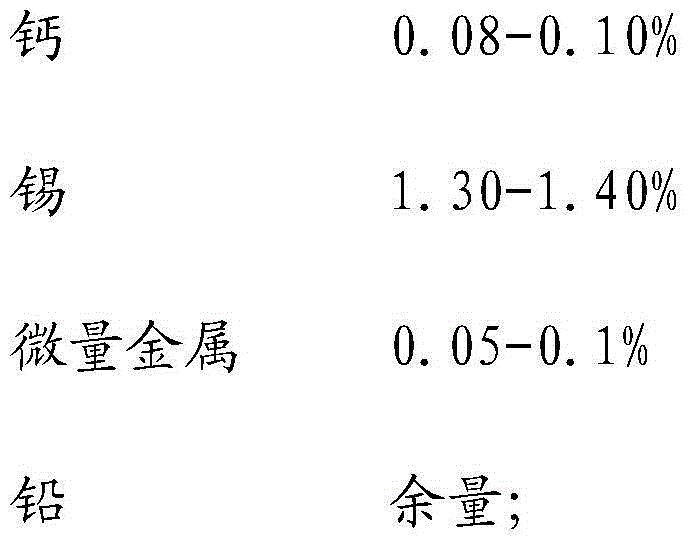

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a method for preparing the above-mentioned lead-carbon battery for motorcycles, comprising the steps of:

[0047] (1) Grid casting: Heat and melt the positive grid alloy and negative grid alloy at 480-510°C, and cast them with positive and negative grid casting machines. The cast grids need to be age-hardened for more than 72 hours Only then can it be used for coating; among them, the thickness ratio of the positive and negative grids is 1:0.80, which ensures that the amount of active materials on the positive and negative plates is scientifically and reasonably matched;

[0048] (2) Preparation of lead paste:

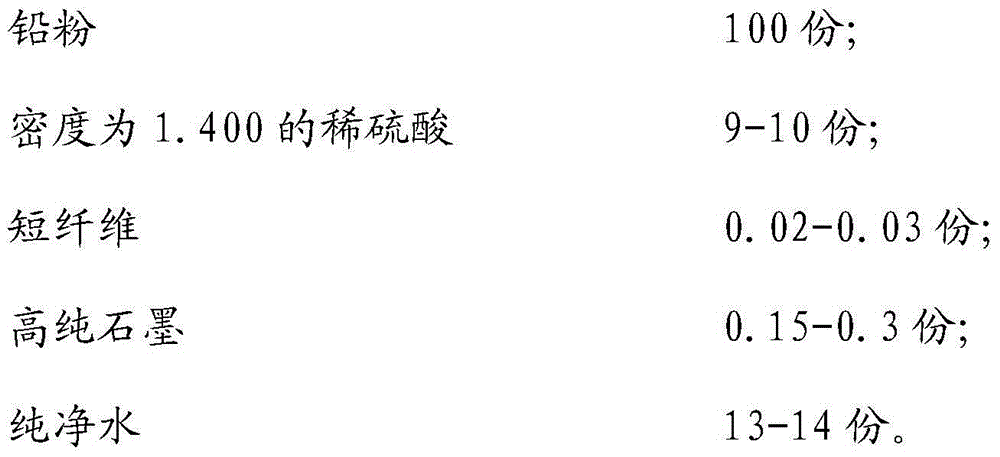

[0049] Preparation of positive lead paste

[0050] Take the lead powder, short fiber and high-purity graphite in the above parts by weight, pour them into the positive electrode and paste machine, add pure water after dry mixing for 3-5 minutes, stir for 2-3 minutes, and then slowly add dilute Sulfuric acid, control to add d...

Embodiment 1-4

[0065] See Table 2 for specific ratios.

[0066] The proportioning table of table 2 embodiment 1-4

[0067]

[0068] The above-mentioned raw materials are prepared according to the following steps for motorcycle lead-carbon batteries, which include the following steps in turn:

[0069] (1) Grid casting: Heat and melt the alloy of the positive grid and the negative grid at 480-510°C, and cast it with a positive and negative grid casting machine. The cast grid needs to be aged for more than 72 hours After hardening, it can be used for coating;

[0070] (2) Preparation of positive and negative lead paste:

[0071] Preparation of positive lead paste

[0072] Take the lead powder, short fiber and high-purity graphite in the above parts by weight, pour them into the positive electrode and paste machine, add pure water after dry mixing for 3-5 minutes, stir for 2-3 minutes, and then slowly add dilute Sulfuric acid, control to add dilute sulfuric acid within 10-15 minutes, cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com