A kind of preparation method of lithium titanate-graphene composite negative electrode material

A graphene composite, negative electrode material technology, applied in nanotechnology, battery electrodes, nanotechnology and other directions for materials and surface science, can solve the problem of uneven surface coating of lithium titanate, poor surface coating tightness, Insufficient density of the coating layer, etc., to achieve the effect of being conducive to high-rate discharge, increasing conductivity, and improving high-rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

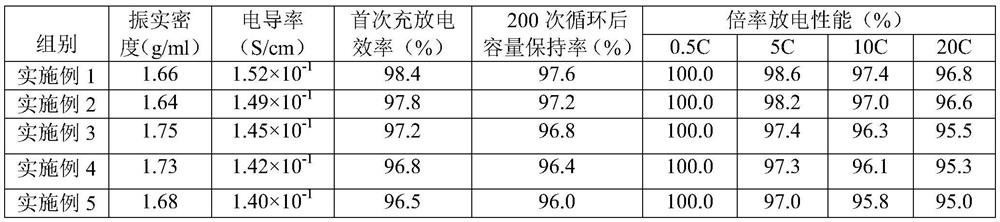

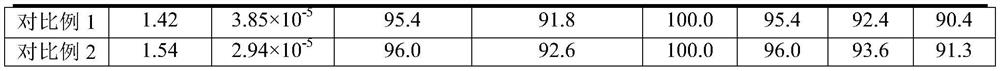

Examples

Embodiment 1

[0024] This embodiment provides a preparation method of lithium titanate-graphene composite negative electrode material, which comprises the following steps:

[0025] Step 1), lithium hydroxide and deionized water are mixed in a mass ratio of 5:95 to form a lithium source solution;

[0026] Step 2), premix ethanol and nitric acid at a volume ratio of 1:0.05, and then add tetra-n-butyl titanate to form a titanium source solution, and the volume ratio of tetra-n-butyl titanate to ethanol is 1:10;

[0027] Step 3), under stirring conditions, according to the ratio of substances Li:Ti=1.0:1, slowly drop the lithium source solution prepared in step 1) into the titanium source solution prepared in step 2) with a dropping funnel, drop The acceleration is 0.1ml / min; after the dropwise addition is completed, adjust the pH value to 8 with ammonia water, and continue to stir for more than 2 hours to obtain a uniformly mixed lithium titanate precursor sol;

[0028] Step 4), under ultraso...

Embodiment 2

[0030] This embodiment provides a preparation method of lithium titanate-graphene composite negative electrode material, which comprises the following steps:

[0031] Step 1), lithium acetate and deionized water are mixed according to a mass ratio of 1:99 to form a lithium source solution;

[0032] Step 2), premix ethanol and acetic acid at a volume ratio of 1:0.01, and then add tetraisopropyl titanate to form a titanium source solution. The volume ratio of tetraisopropyl titanate to ethanol is 1:20;

[0033] Step 3), under stirring conditions, according to the amount ratio Li:Ti=0.6:1, use the dropping funnel to slowly add the lithium source solution prepared in step 1) to the titanium source solution prepared in step 2), drop The acceleration is 1ml / min; after the dropwise addition is completed, adjust the pH value to 8 with ammonia water, and continue to stir for more than 2 hours to obtain a uniformly mixed lithium titanate precursor sol;

[0034] Step 4), under ultrasoni...

Embodiment 3

[0036] This embodiment provides a preparation method of lithium titanate-graphene composite negative electrode material, which comprises the following steps:

[0037] Step 1), lithium oxalate and deionized water are mixed in a mass ratio of 10:90 to form a lithium source solution;

[0038] Step 2), premix ethanol and oxalic acid at a volume ratio of 1:0.1, and then add tetra-n-butyl titanate to form a titanium source solution, and the volume ratio of tetra-n-butyl titanate to ethanol is 1:5;

[0039] Step 3), under stirring conditions, according to the ratio of substances Li:Ti=0.8:1, slowly drop the lithium source solution prepared in step 1) into the titanium source solution prepared in step 2) with a dropping funnel, drop The acceleration is 3ml / min; after the addition is completed, adjust the pH value to 8 with ammonia water, and continue to stir for more than 2 hours to obtain a uniformly mixed lithium titanate precursor sol;

[0040] Step 4), under ultrasonic conditions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com