Lithium battery isolation membrane and lithium battery using same

A technology for separators and lithium batteries, applied in secondary batteries, battery pack components, circuits, etc., to achieve good high-rate discharge effects, low ionic impedance, and favorable effects for large-scale promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Existing lithium battery

[0029] Taking the existing lithium battery, the thickness, porosity, air permeability and pore size of the separator are shown in Table 1.

Embodiment 2

[0030] Embodiment 2 Lithium battery of the present invention

[0031] Replace the separator of the lithium battery of Example 1 with the separator of the present invention. The parameters of the separator of the present invention are shown in Table 1, and the rest are the same as in Example 1.

[0032] The performance parameter of isolation film in the embodiment of table 1

[0033] Separator

Embodiment 3

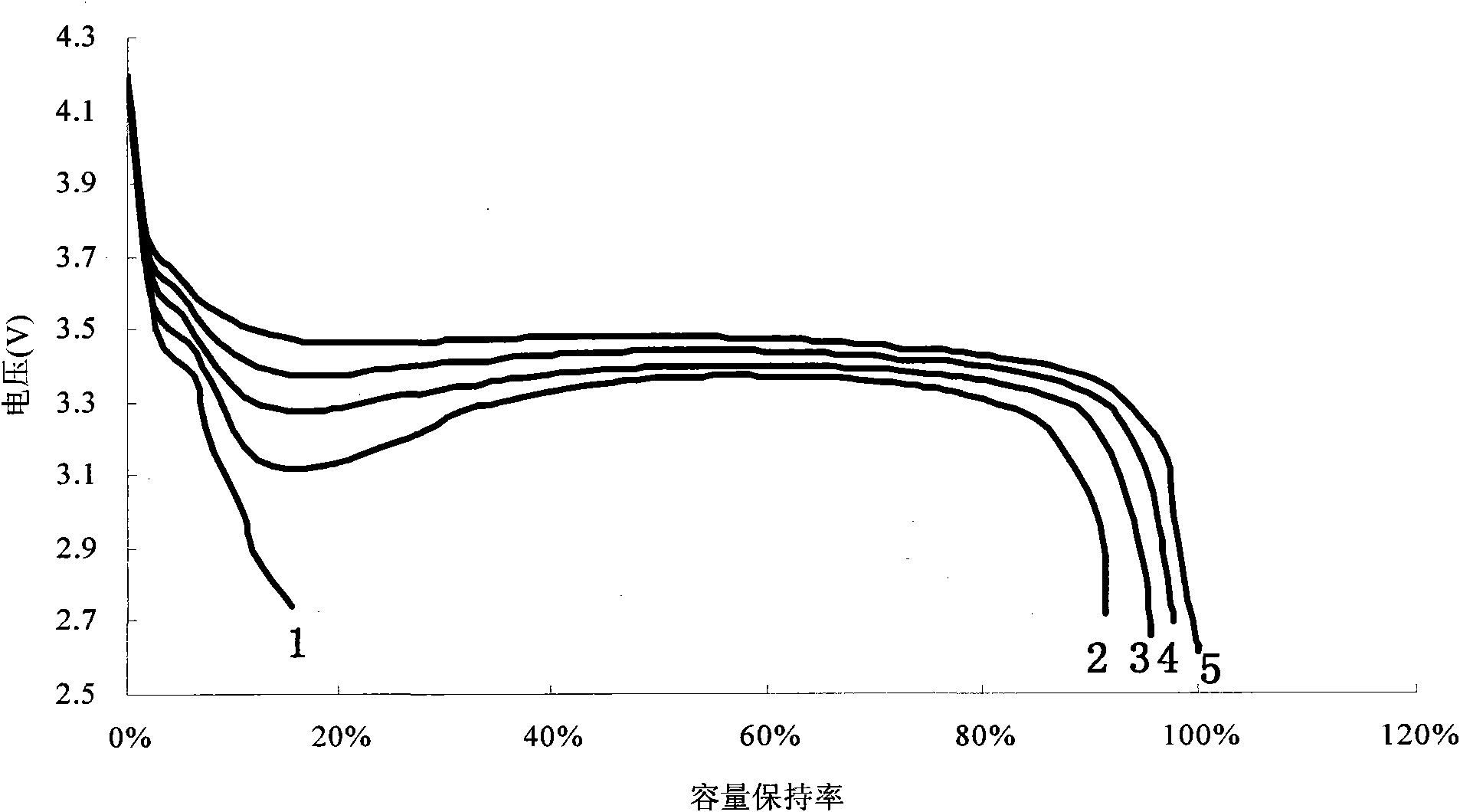

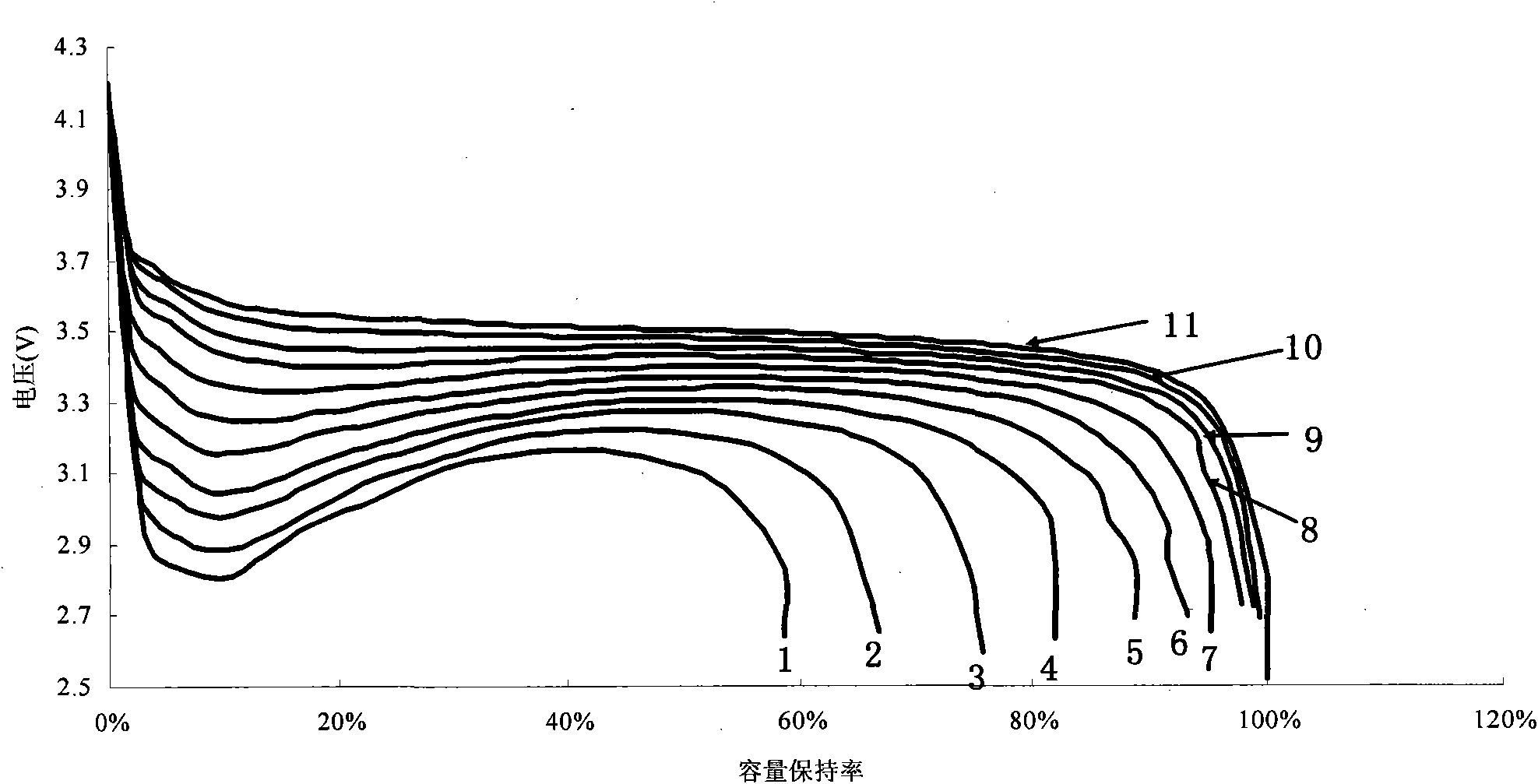

[0035] Measure the discharge rate situation of embodiment 1 lithium battery and embodiment 2 lithium battery, the result is respectively as follows figure 1 and figure 2 shown.

[0036] From figure 1 It can be seen that the separator of the existing lithium battery cannot be discharged normally under the current of 55C, while figure 2 It can be seen that the lithium battery adopting the separator of the present invention also has a very high capacity percentage at a current of 55C.

[0037] From figure 2 It can be seen that after adopting the separator of the present invention, the lithium battery can increase the maximum discharge current to above 85C, and the effect is very obvious.

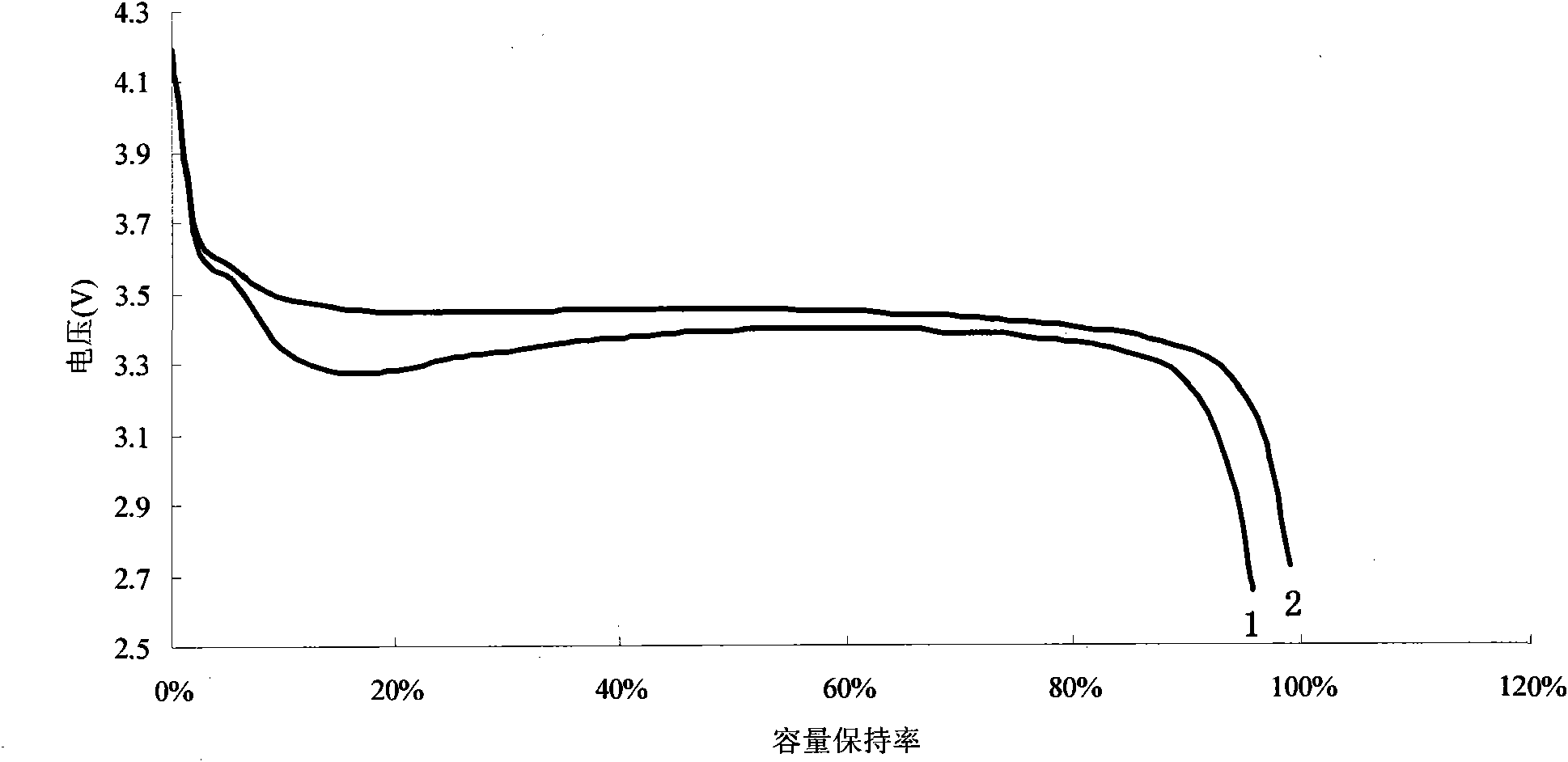

[0038] With the lithium battery of embodiment 1 and embodiment 2, under the same discharge current situation, carry out the comparison of discharging situation, the result is as follows image 3 shown. From image 3 It can be seen that under the same discharge current situation, takin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com