Process for preparing gamma-AlON powder by chemical coprecipitation and carbothermal reduction method

A technology of chemical co-precipitation and reduction method, applied in the field of chemical co-precipitation carbothermal reduction method to prepare γ-AlON powder, can solve the problems of excessive nitriding and incomplete nitriding reaction of powder, achieve uniform particle size distribution, avoid Effects of uneven mixing of reactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

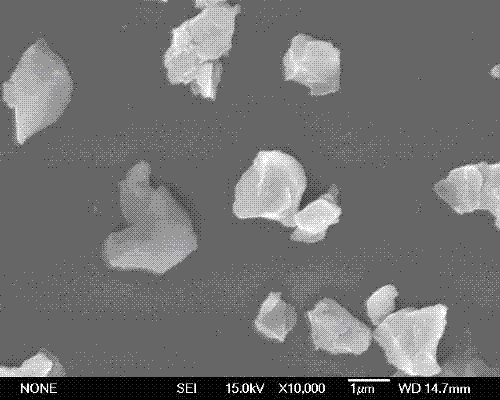

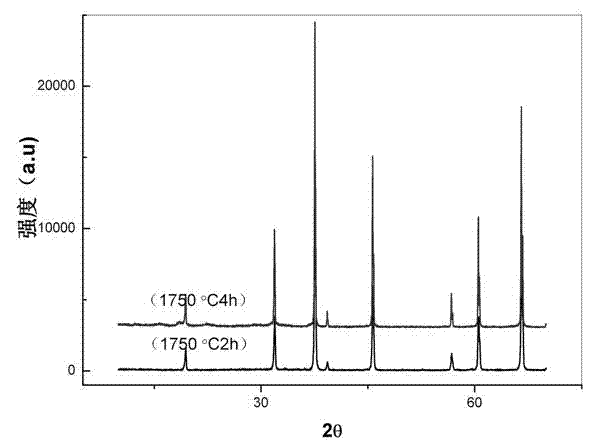

Embodiment 1

[0023] 45.455g Al(NO 3 ) 3 .H 2 O, 5.4g urea CO(NH 2 ) 2 Add 4.5g of PEG (polyethylene glycol, molecular weight 5000) into 300ml of deionized water, and stir for 30min at 80-90°C to obtain a transparent and uniform solution. 0.5g stearic acid (C 18 h 36 o 2 ), 6g ammonium bicarbonate (NH 4 HCO 3 ) and 0.384g (mass fraction: 5.9%) nano-carbon black (average particle size is about 18nm) were added to 200ml deionized water, and stirred at 150°C for 1h to obtain a stable suspension. Then slowly add the hydrolyzed solution of aluminum nitrate into the ammonium bicarbonate solution suspended with carbon black, and stir while adding. After all the addition is completed, continue to add ammonia water to adjust the pH value to 8, and continue to stir for half an hour. After that, the desired precursor precipitation can be obtained. Precursor precipitates were aged at room temperature for 24 h, filtered, washed three times with deionized water and once with absolute ethanol. ...

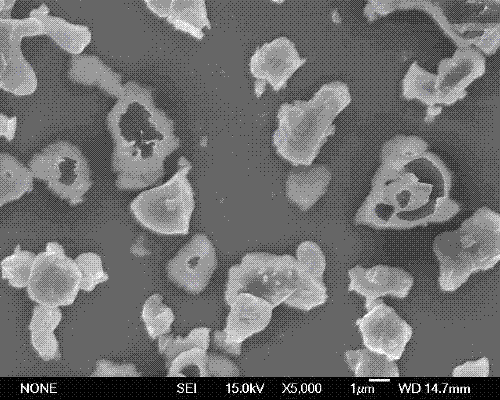

Embodiment 2

[0025] 45.455g Al(NO 3 ) 3 .H 2 O, 5.4g urea CO(NH 2 ) 2 Add 4.5g PEG (molecular weight 5000) into 300ml deionized water and stir for 30min at 80-90°C to obtain a transparent and uniform solution. 0.5g stearic acid (C 18 h 36 o 2 ), 6g ammonium bicarbonate (NH 4 HCO 3) and 0.384g (mass fraction: 5.9%) nano-carbon black (average particle size is about 18nm) were added to 200ml deionized water, and stirred at 150°C for 1h to obtain a stable suspension. Then slowly add the hydrolyzed solution of aluminum nitrate into the ammonium bicarbonate solution suspended with carbon black, and stir while adding. After all the drops are completed, continue to add ammonia water to adjust the pH value to 9, and continue to stir for half an hour. After that, the desired precursor precipitation can be obtained. Precursor precipitates were aged at room temperature for 24 h, filtered, washed three times with deionized water and once with absolute ethanol. The resultant was dried at 80° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com