Exterior thermal-insulation and exterior decoration system for external wall and construction method therefor

A construction method and external thermal insulation technology, applied in thermal insulation, walls, climate change adaptation, etc., can solve the problems of restricting the development of energy-saving wall buildings, complicated construction technology, and long construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

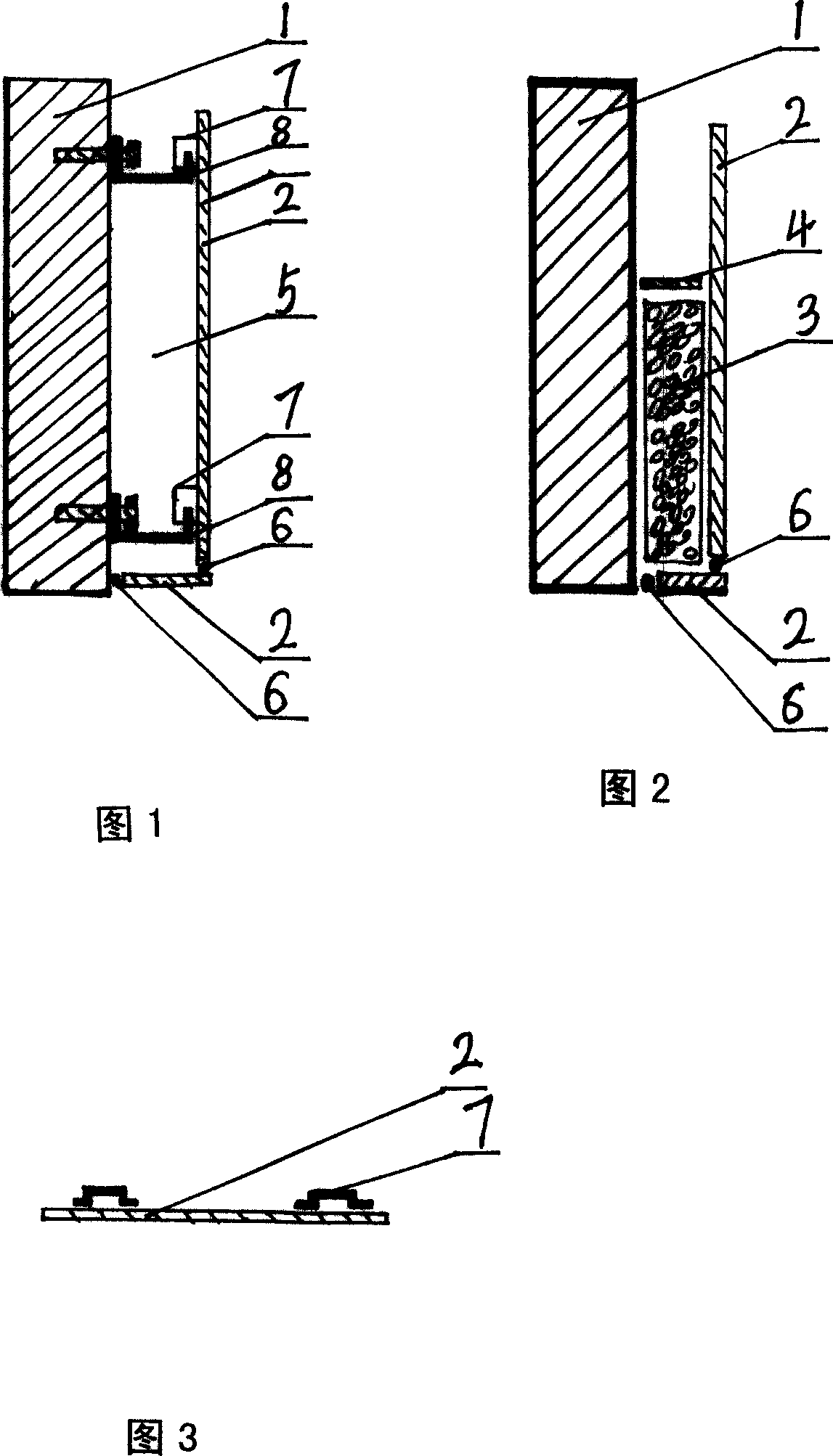

[0007] As shown in Figure 1, Figure 2, and Figure 3, pretreatment is carried out on the outside of the wall 1 of the building to enable the wall to be firmly bonded to the cement. The stone dry hanging technology is used on the treated wall 1 to decorate The ceramic tile 2 is fixed on the outside of the wall 1, that is to say: the connecting piece (B) 8 is fixed on the wall 1, and then the decorative ceramic tile 2 is fixed through the connecting piece (A) 7. The connecting piece (A) 7 is It is fixed on the decorative ceramic tile 2 with an adhesive in advance. The distance between the wall 1 and the decorative ceramic tile 2 is specifically set according to the thermal insulation requirements of the wall 1. The gap between the decorative ceramic tile 2 and the decorative ceramic tile 2 and the decorative ceramic tile 2 and the wall 1 The gap between the two is sealed by a prefabricated sealing strip 6, so that it can be poured into the insulation layer 5 with a mixture of light i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com