Dual air spring with shared additional air chamber and control method and application of dual air spring

A technology of air springs and additional air chambers, applied in the direction of springs, spring/shock absorbers, gas shock absorbers, etc., can solve the problems that a single air spring cannot meet the requirements of the vibration damping system, and cannot control the air spring in real time, and achieve Reduced no-load mass, simple structure, and reduced occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

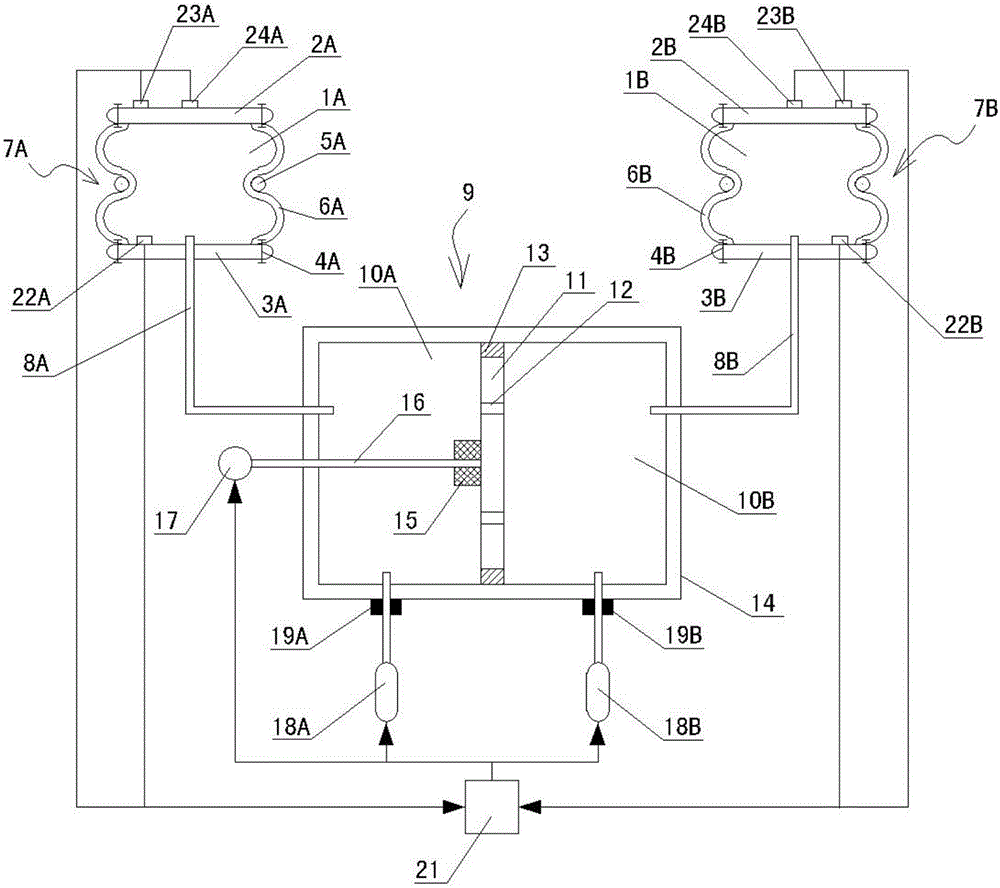

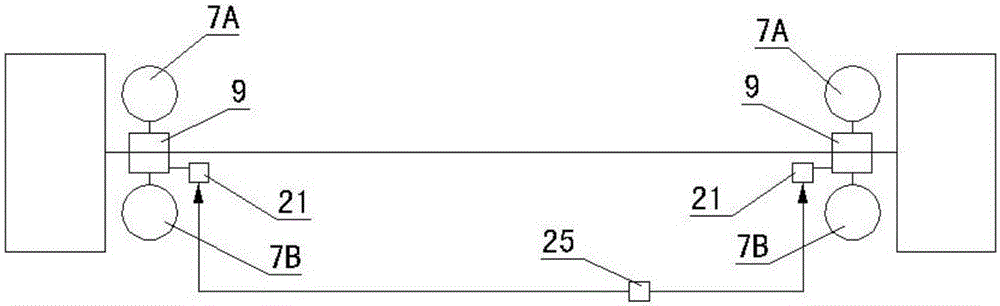

[0033] see figure 1 , the double air spring with shared additional air chamber in this embodiment includes left air spring 7A and right air spring 7B, and shared additional air chamber 9 is set between said left air spring 7A and right air spring 7B and is used for controlling A controller 21 for the working mode of the additional gas chamber 9 .

[0034] like figure 1 As shown, the left main air chamber 1A in the left air spring 7A is sealed by a hyperbolic left rubber bag 6A fixedly connected to the left upper cover 2A at the top and fixedly connected to the left lower cover 3A at the bottom through the left fixed connection device 4A. The air chamber is provided with a left waist ring 5A at the waist of the left rubber bag 6A in a hyperbolic shape, which is used to limit the radial expansion of the waist of the left rubber bag 6A and prevent mutual friction between the hyperbolas; the left lower cover plate 3A The center of the left hose 8A communicates with the left m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com